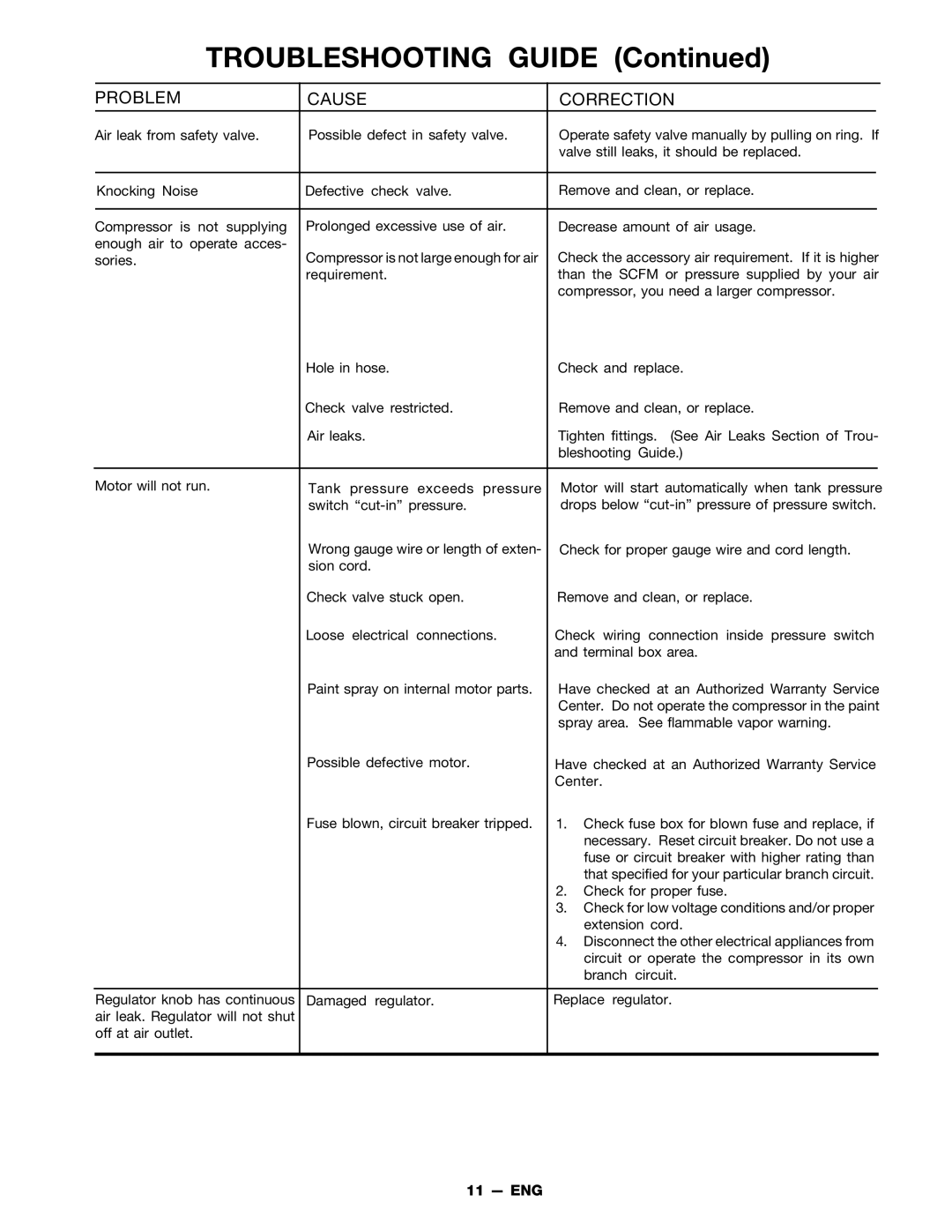

TROUBLESHOOTING GUIDE (Continued)

PROBLEM | CAUSE | CORRECTION |

|

Air leak from safety valve. | Possible defect in safety valve. | Operate safety valve manually by pulling on ring. If | |

|

| valve still leaks, it should be replaced. | |

|

|

|

|

Knocking Noise | Defective check valve. | Remove and clean, or replace. | |

|

|

|

|

Compressor is not supplying | Prolonged excessive use of air. | Decrease amount of air usage. | |

enough air to operate acces- | Compressor is not large enough for air | Check the accessory air requirement. If it is higher | |

sories. | |||

| requirement. | than the SCFM or pressure supplied by your air | |

|

| compressor, you need a larger compressor. | |

| Hole in hose. | Check and replace. | ||

| Check valve restricted. | Remove and clean, or replace. | ||

| Air leaks. | Tighten fittings. (See Air Leaks Section of Trou- | ||

|

| bleshooting Guide.) | ||

|

|

|

| |

Motor will not run. | Tank pressure exceeds pressure | Motor will start automatically when tank pressure | ||

| switch | drops below | ||

| Wrong gauge wire or length of exten- Check for proper gauge wire and cord length. | |||

| sion cord. |

|

|

|

| Check valve stuck open. | Remove and clean, or replace. | ||

| Loose electrical connections. | Check wiring connection inside pressure switch | ||

|

| and terminal box area. | ||

| Paint spray on internal motor parts. | Have checked at an Authorized Warranty Service | ||

|

| Center. Do not operate the compressor in the paint | ||

|

| spray area. See flammable vapor warning. | ||

| Possible defective motor. | Have checked at an Authorized Warranty Service | ||

|

| Center. | ||

| Fuse blown, circuit breaker tripped. | 1. Check fuse box for blown fuse and replace, if | ||

|

|

| necessary. Reset circuit breaker. Do not use a | |

|

|

| fuse or circuit breaker with higher rating than | |

|

|

| that specified for your particular branch circuit. | |

|

| 2. Check for proper fuse. | ||

|

| 3. | Check for low voltage conditions and/or proper | |

|

|

| extension cord. | |

|

| 4. | Disconnect the other electrical appliances from | |

|

|

| circuit or operate the compressor in its own | |

|

|

| branch circuit. | |

|

|

|

| |

Regulator knob has continuous | Damaged regulator. | Replace regulator. | ||

air leak. Regulator will not shut |

|

|

|

|

off at air outlet. |

|

|

|

|

11 — ENG