INSTALLATION AND BREAK-IN PROCEDURES

Location of the Air Compressor

Your compressor comes to you completely assembled and ready for use. Operate the air compressor in a dry, clean, cool and well ventilated area. The air compressor pump and case are designed to allow for proper cooling. Clean or blow off dust or dirt that collects on the air compressor. A clean air compressor runs cooler and provides longer service. The ventilation openings on your air compressor are necessary to maintain proper operating temperature. Do not place rags or other containers on or near these openings.

Extension Cords

Use extra air hose instead of an extension cord to avoid voltage drop and power loss to the motor. Low voltage can cause damage to the motor.

If an extension cord must be used, be sure it is:

•a

•in good condition

•no longer than 50 feet

•14 gauge (AWG) or larger. (Wire size increases as gauge number decreases.) 12 AWG, 10 AWG and 8 AWG may also be used. DO NOT USE 16 OR 18 AWG.

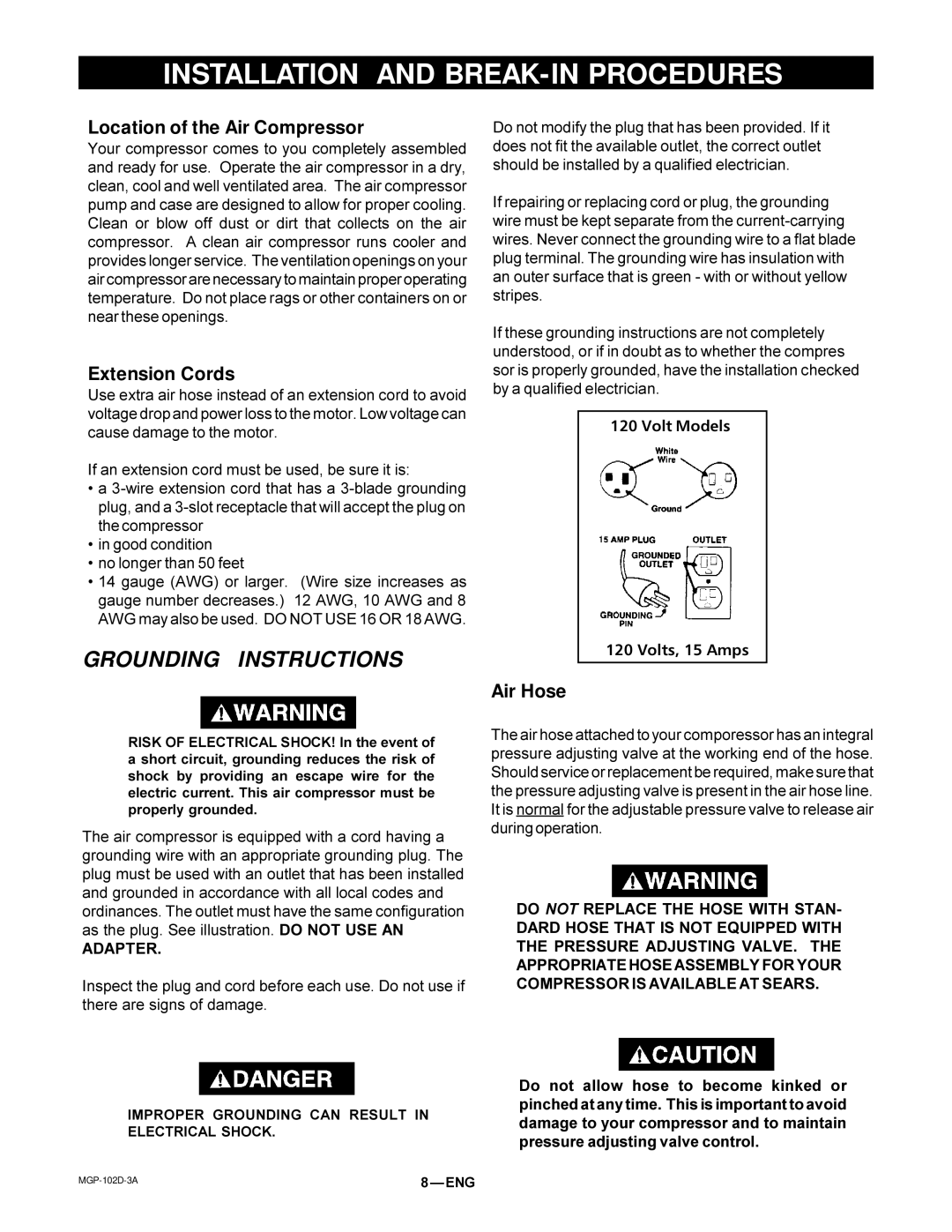

GROUNDING INSTRUCTIONS

RISK OF ELECTRICAL SHOCK! In the event of a short circuit, grounding reduces the risk of shock by providing an escape wire for the electric current. This air compressor must be properly grounded.

The air compressor is equipped with a cord having a grounding wire with an appropriate grounding plug. The plug must be used with an outlet that has been installed and grounded in accordance with all local codes and ordinances. The outlet must have the same configuration as the plug. See illustration. DO NOT USE AN

ADAPTER.

Inspect the plug and cord before each use. Do not use if there are signs of damage.

IMPROPER GROUNDING CAN RESULT IN ELECTRICAL SHOCK.

Do not modify the plug that has been provided. If it does not fit the available outlet, the correct outlet should be installed by a qualified electrician.

If repairing or replacing cord or plug, the grounding wire must be kept separate from the

If these grounding instructions are not completely understood, or if in doubt as to whether the compres sor is properly grounded, have the installation checked by a qualified electrician.

120 Volt Models

120 Volts, 15 Amps

Air Hose

The air hose attached to your comporessor has an integral pressure adjusting valve at the working end of the hose. Should service or replacement be required, make sure that the pressure adjusting valve is present in the air hose line. It is normal for the adjustable pressure valve to release air during operation.

DO NOT REPLACE THE HOSE WITH STAN- DARD HOSE THAT IS NOT EQUIPPED WITH THE PRESSURE ADJUSTING VALVE. THE APPROPRIATE HOSE ASSEMBLY FOR YOUR COMPRESSOR IS AVAILABLE AT SEARS.

Do not allow hose to become kinked or pinched at any time. This is important to avoid damage to your compressor and to maintain pressure adjusting valve control.

8 |