OPERATION

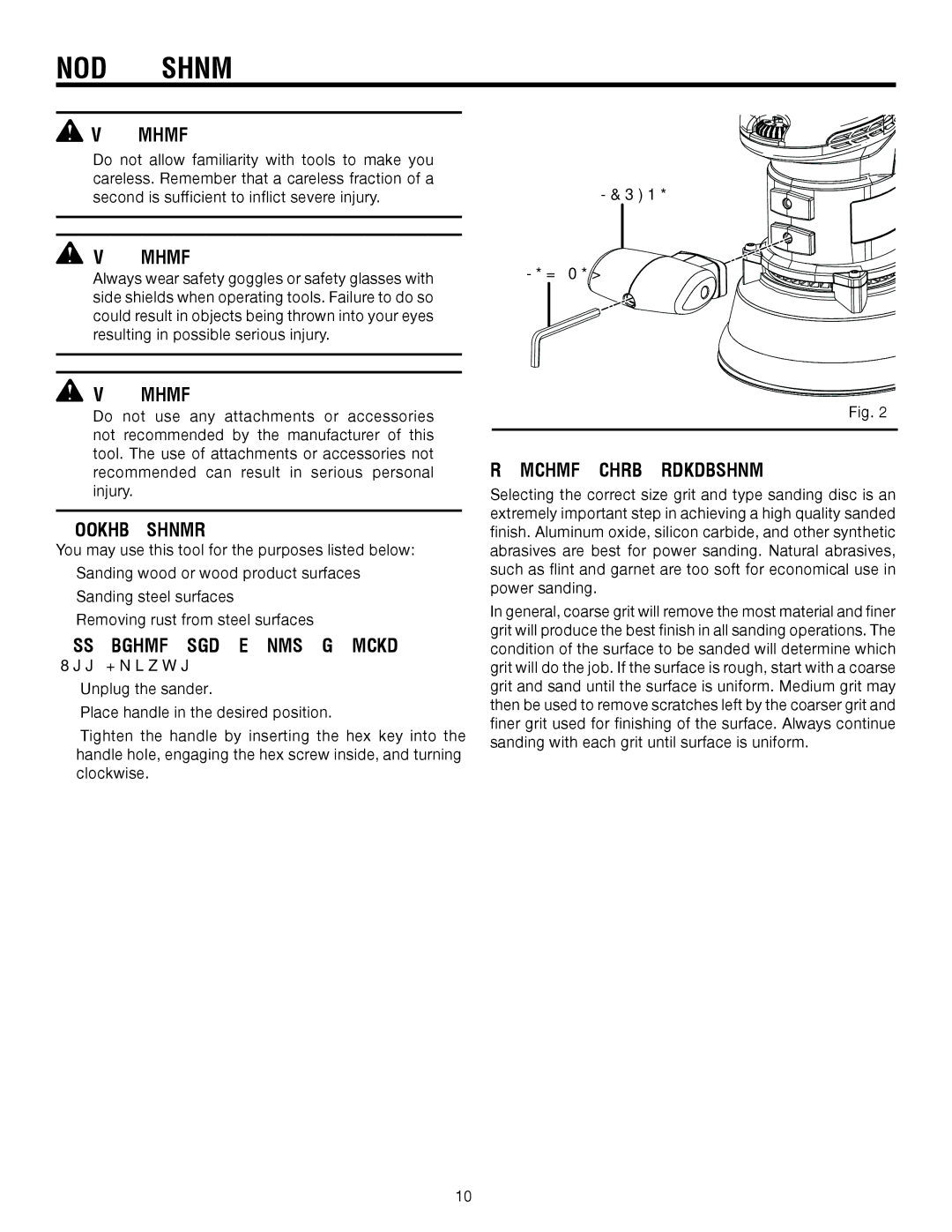

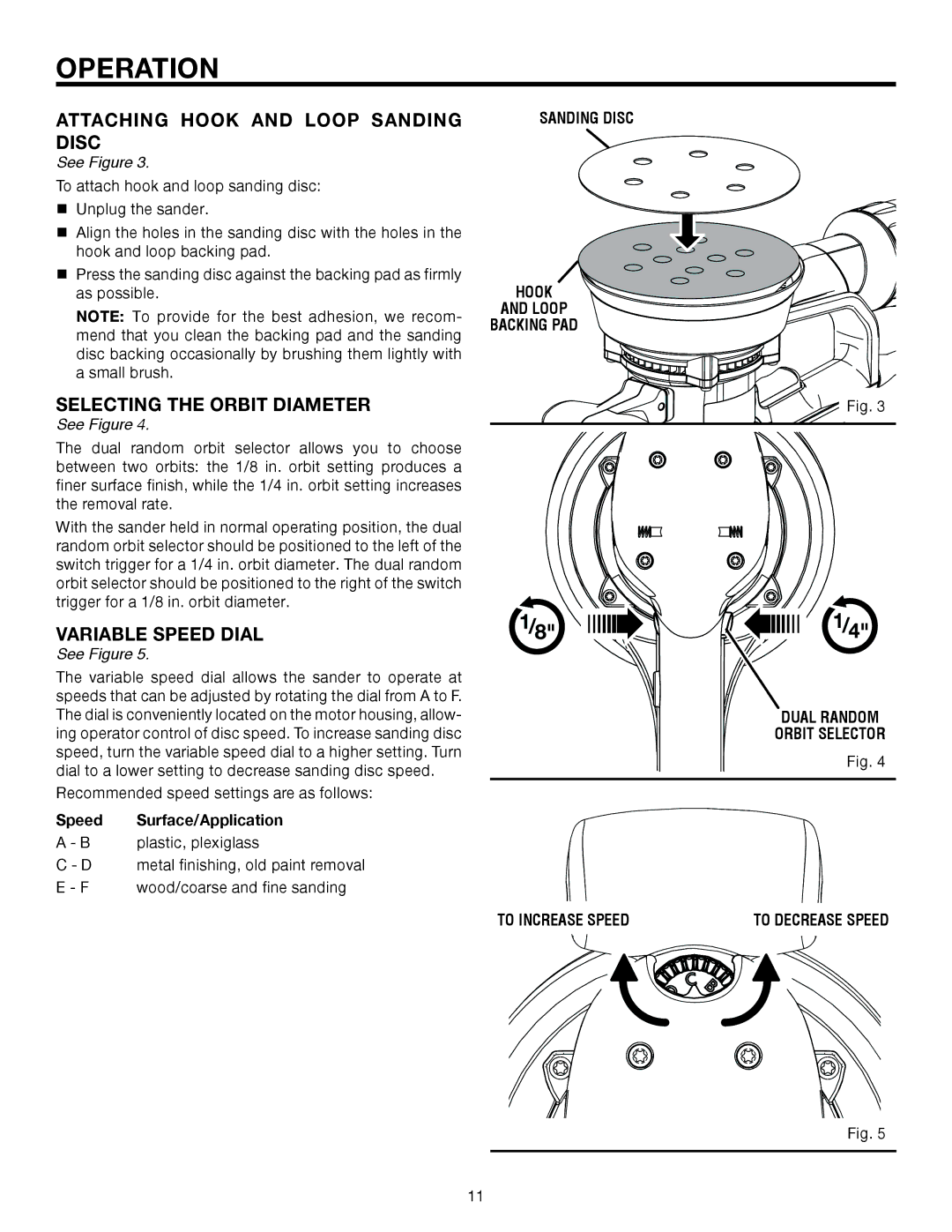

ATTACHING HOOK AND LOOP SANDING DISC

See Figure 3.

To attach hook and loop sanding disc:

Unplug the sander.

Align the holes in the sanding disc with the holes in the hook and loop backing pad.

Press the sanding disc against the backing pad as firmly as possible.

NOTE: To provide for the best adhesion, we recom- mend that you clean the backing pad and the sanding disc backing occasionally by brushing them lightly with a small brush.

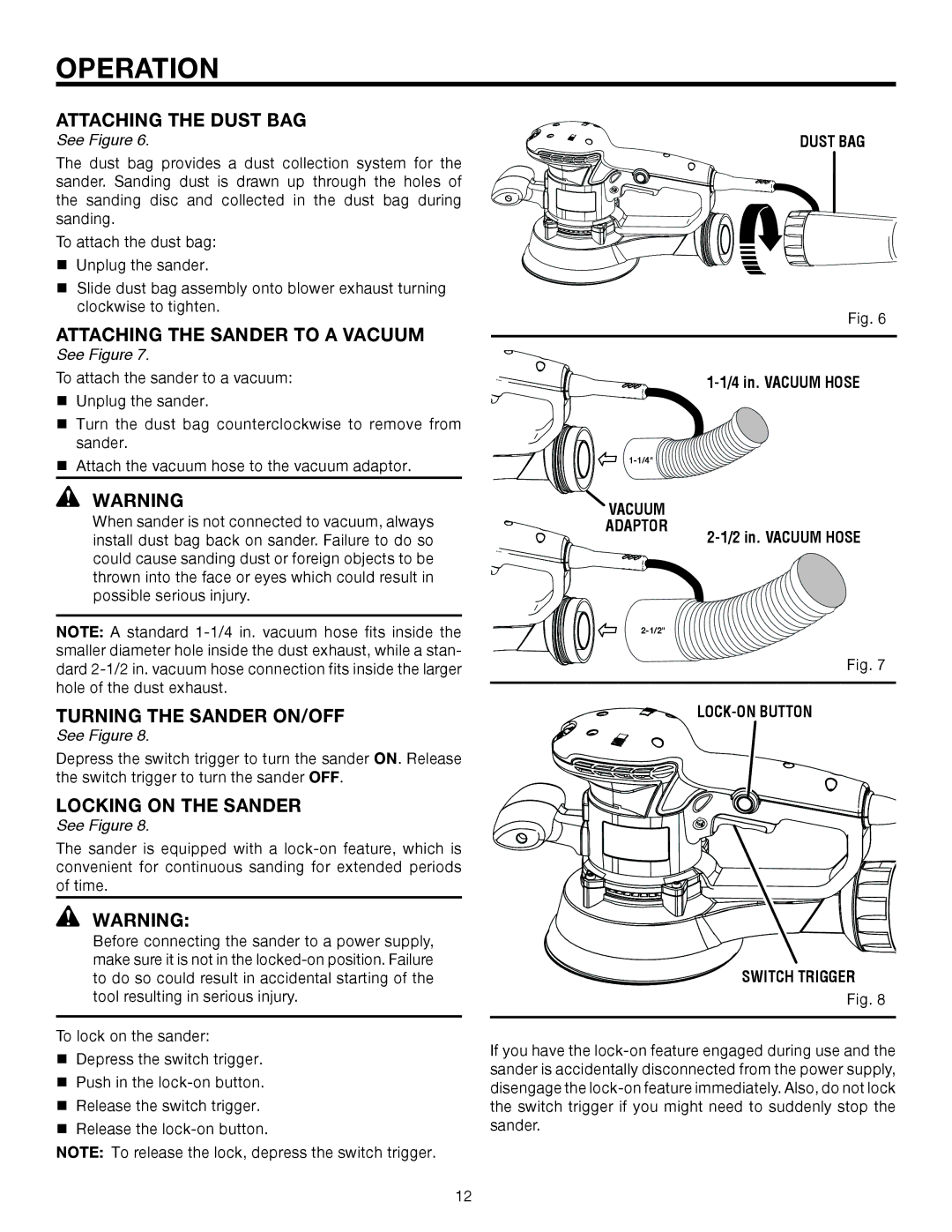

SELECTING THE ORBIT DIAMETER

See Figure 4.

The dual random orbit selector allows you to choose between two orbits: the 1/8 in. orbit setting produces a finer surface finish, while the 1/4 in. orbit setting increases the removal rate.

With the sander held in normal operating position, the dual random orbit selector should be positioned to the left of the switch trigger for a 1/4 in. orbit diameter. The dual random orbit selector should be positioned to the right of the switch trigger for a 1/8 in. orbit diameter.

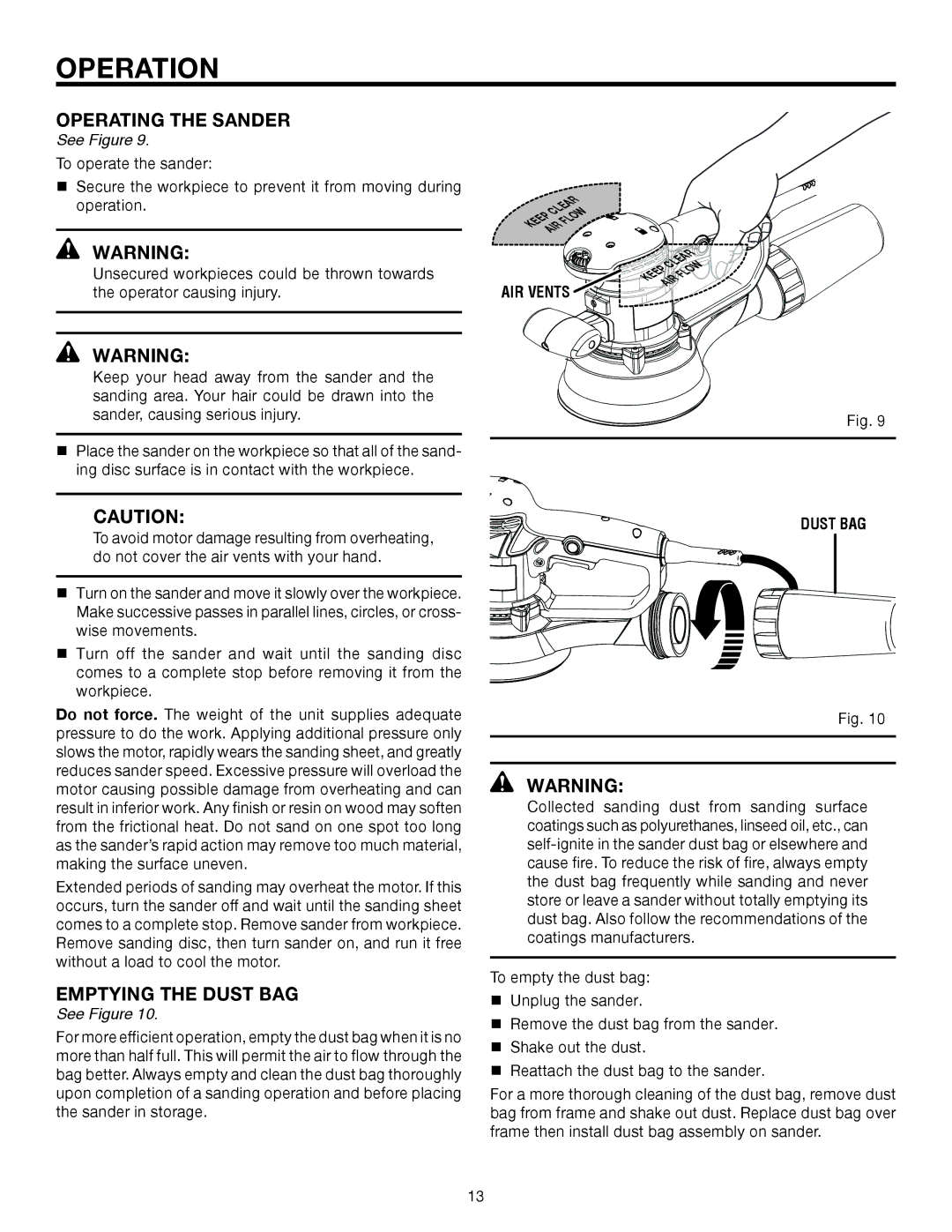

VARIABLE SPEED DIAL

See Figure 5.

The variable speed dial allows the sander to operate at speeds that can be adjusted by rotating the dial from A to F. The dial is conveniently located on the motor housing, allow- ing operator control of disc speed. To increase sanding disc speed, turn the variable speed dial to a higher setting. Turn dial to a lower setting to decrease sanding disc speed.

Recommended speed settings are as follows:

Speed Surface/Application

A - B plastic, plexiglass

C - D metal finishing, old paint removal

E - F wood/coarse and fine sanding

SANDING DISC

HOOK

AND LOOP

BACKING PAD

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Fig.

Fig.![]() 3

3

DUAL RANDOM

ORBIT SELECTOR

Fig. 4

TO INCREASE SPEED | TO DECREASE SPEED |

Fig. 5

11