Specifications

Operating | |

Pressure |

|

Staple Capacity | 80 |

Staple Length / | 3/4” to |

Type | |

Air Inlet | 1/4” NPT (18 TPI - male/female |

| adapter included) |

Note: SKU’s 40072 and 97521 contain the Stapler by itself.

SKU 40073 contains the Stapler, pneumatic tool oil, 2 hex wrenches, and a blowmold carrying case.

Unpacking

When unpacking, make sure the item is intact and undamaged. If any parts are missing or broken, call Harbor Freight Tools at

Operation

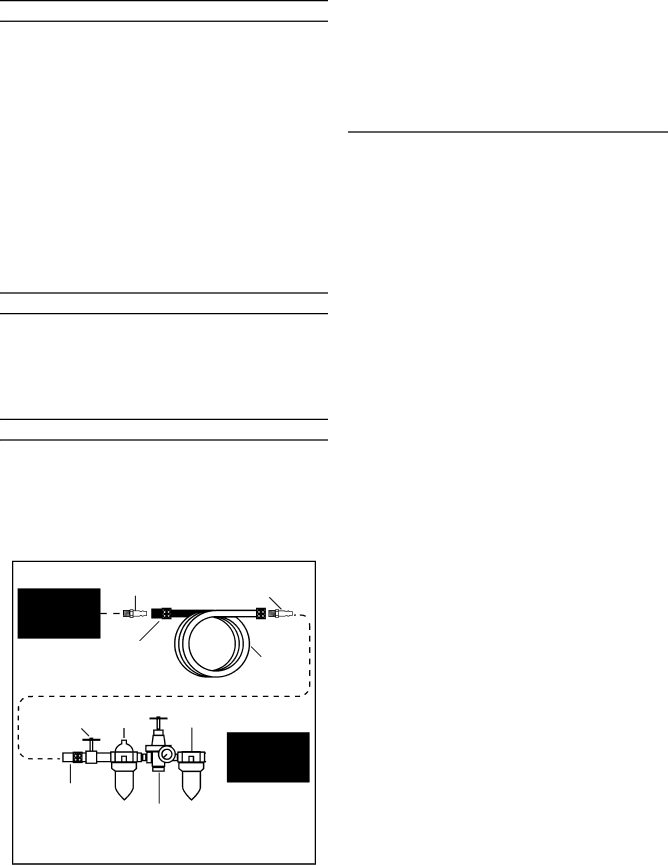

For best service, incorporate an oiler, regulator, and inline filter, as shown in the diagram below. Hoses, couplers, oilers, regulators, and filters are all available at Harbor Freight Tools.

Coupler | Coupler |

Plug | Plug |

Tool

Quick

CouplerAir Hose

on Reel

Valve | Oiler | Filter |

Air

![]() Compressor

Compressor

Regulator with

Pressure Gauge

Recommended Air Line Components

REV 10a

Note: To connect this tool, we recommend a quick coupler/adapter (not included). Coupler/adapters are available at Harbor Freight Tools. For smoother operation, put

Testing the Single Sequential Safety

Trip Mechanism

Warning: Even though the Stapler should be empty during this procedure, always point the Stapler at a piece of scrap wood when testing.

1.Make sure the tool is disconnected from the power supply.

2.Completely empty the magazine of staples.

3.The Stapler should not fire if the nose is not depressed against the workpiece.

4.Check that the Trigger (39) and the Safety (52) move freely, without sticking.

5.Connect the air supply to the tool at the Air Plug (82) set at the recommended

6.Test the tool by depressing the Safety (52) against the workpiece without pulling the Trigger (39). The tool must not cycle (fire). If it cycles (fires), stop immediately and take the tool to a qualified service technician.

7.Hold the tool away or off of the workpiece. The Safety (52) of the tool should return to its original position. Squeeze the Trigger (39). The tool should not cycle (fire). If it cycles

(fires), stop immediately and take the tool to a qualified service technician.

8.Depress the Safety (52) against the workpiece and squeeze the Trigger (39).

The tool must cycle (fire) once only. Release the trigger and squeeze it again.

The tool must cycle (fire) once only.

SKU’s 40072, | For technical questions, please call | Page 7 |

40073, & 97521 |

|

|