The transformer must also not be mounted within 0.6m of a bath or shower cubicle, up to a height of 2.25m.

The transformer must not be mounted where ambient temperatures are likely to exceed 40°C.

Fixing the transformer directly

1.Remove the two screws securing the cover, remove cover.

2.Position the transformer on the wall, and mark the two fixing holes.

3.Drill and plug the two holes and fix the transformer with the screws supplied.

For loft mounting:

The transformer can be fixed to a wooden surface with the two screws supplied.

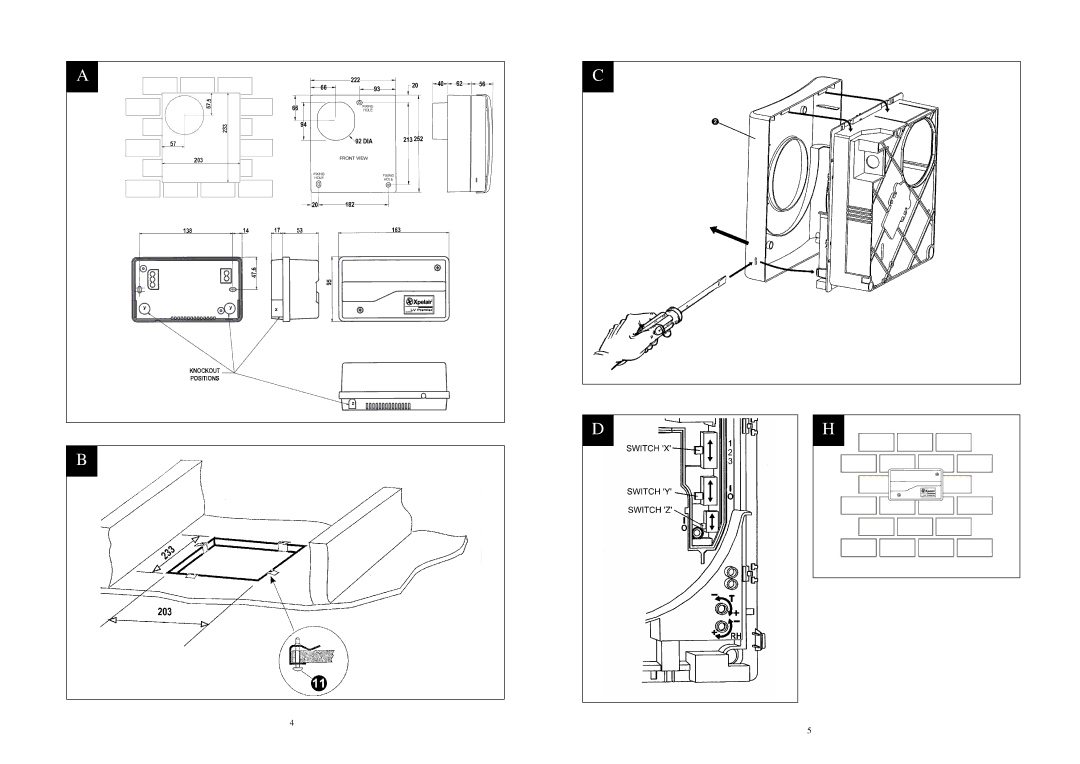

For fixed surface wiring:

Use the rectangular knockouts on each side (X). These accept 25 x 16mm trunking (not supplied)

For concealed wiring:

Use the round knockouts (Y).

For connection to a window mounted fan: Use knockout (Z). Use flexible cable.

When using the side entries with flexible cable, a hole suitable for the cable size must be made centrally in the rectangular section.

Wire the Fan

1.Isolate the electricity supply and remove all fuses.

The terminal block will accept cable up to 1.5mm².

2.A means for disconnection in all poles must be incorporated in the fixed wiring in accordance with the wiring rules.

3.Use suitably rated 3-core or 4-core cable dependent on application.

4.Remove the retaining screws of the terminal cover •, if still in position.

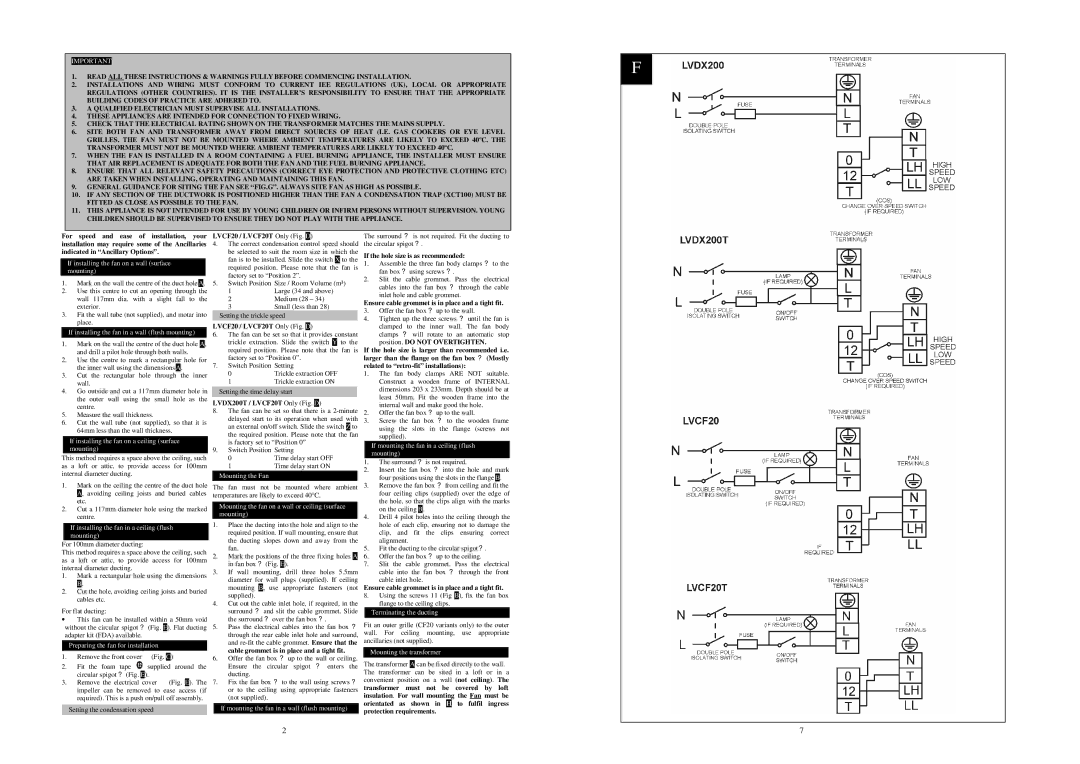

5.Wire the fan as shown in  using the cable clamp provided. Check fan model to diagram. LVDX200T: “LH” = Live (High Speed) / “LL” = Live (Low Speed)

using the cable clamp provided. Check fan model to diagram. LVDX200T: “LH” = Live (High Speed) / “LL” = Live (Low Speed)

6.Replace the terminal cover • and fasten the retaining screws.

7.See section on “User adjustments” if you wish to use settings other than those that have been factory set.

8.Refit the front cover • (Fig.  ).

).

9.Connect the cable from the isolating switch to electrical supply wiring, and re-check installation.

10.Refit fuses before turning on electricity supply.

11.For fixed wiring circuits, the protective fuse for the appliance must not exceed 5A.

For Australia Only

LVCF20 – Connection to the supply – flexible 3- core cable with 3 pin plug top for insertion into an approved 10A wall mounted surface switch with at least 3mm clearance between contacts.

ALL OTHERS – Permanently connected to the supply and a remote switch controls operation. They should be directly wired to the supply through an approved 10A wall mounted surface switch with at least 3mm clearance between contacts.

Wire the Transformer

Always wire via the cable clamp.

1.Remove the cable clamps.

2.Wire the transformer as shown in  . Check the fan model to diagram.

. Check the fan model to diagram.

3.Ensure all connections are tight.

4.Replace the clamps and two screws. Ensure the cable is firmly retained by the clamp.

5.Replace the transformer cover with the two screws.

6.Switch off the mains electrical supply and remove fuses.

7.Connect the cable from the isolating switch to the electrical supply wiring.

8.For fixed wiring circuits the protective fuse for the appliance must not exceed 5A.

User adjustments

Before making any adjustments, isolate the fan completely from the mains supply, check specification below to see which features apply to your fan.

1.Remove the front cover and replace after adjustment (Fig.  ).

).

LVDX200

There are no user adjustments for the LVDX200 fan.

LVDX200T

1.The timer over-run period can be adjusted between approximately 30 seconds and 20 minutes. Use an electrician’s screwdriver and turn screw “T” (Fig.  ), clockwise to increase time, anti-clockwise to decrease. (Factory preset to approximately 10 minutes).

), clockwise to increase time, anti-clockwise to decrease. (Factory preset to approximately 10 minutes).

LVCF20

1.The humidity setting is adjustable between approximately 50% and 90% relative humidity. Use an electrician’s screwdriver, and turn screw “RH” (Fig.  ), clockwise to increase the relative humidity setting and anti- clockwise to decrease. (Note: the fan is more sensitive at 50% RH than at 90%).

), clockwise to increase the relative humidity setting and anti- clockwise to decrease. (Note: the fan is more sensitive at 50% RH than at 90%).

LVCF20T

1.The timer over-run period can be adjusted between approximately 30 seconds and 20 minutes. Use an electrician’s screwdriver and turn screw “T” (Fig.  ), clockwise to increase time, anti-clockwise to decrease. (Factory preset to approximately 10 minutes).

), clockwise to increase time, anti-clockwise to decrease. (Factory preset to approximately 10 minutes).

2.The humidity setting is adjustable between approximately 50% and 90% relative humidity. Use an electrician’s screwdriver, and turn screw “RH” (Fig.  ), clockwise to increase the relative humidity setting and anti- clockwise to decrease. (Note: the fan is more sensitive at 50% RH than at 90%).

), clockwise to increase the relative humidity setting and anti- clockwise to decrease. (Note: the fan is more sensitive at 50% RH than at 90%).

Using the Fan

LVDX200

Operate the fan using the external On/Off switch. Repeat to switch off. The fan speed is pre-set by the Installer to either high or low speed.

Both speeds can be selected when wired through a change over switch Part No. 90108AW.

LVDX200T

Operate the fan using the external on/off switch. Repeat to switch off.

When the switch is turned off, the fan continues to operate for the selected over-run timer period. Top light “I” is lit when the external on/off switch is turned on.

The fan speed is pre-set by the installer to either high or low speed. (If a change over switch has been installed then the user can switch between high speed and low speed.)

Time delay start feature on or off

This is set by the installer to provide a 2-minute time delay start when the fan is switched on using the external on/off switch.

LVCF20 / LVCF20T

Switched Operation

The fan can be wired with a separate on/off switch. Fan operates at condensation speed when switched on. Top light “I” is lit when the separate on/off switch is switched on. When switched off, the fan will continue to operate if the humidity level has not reached that set by adjusting screw “RH”. LVCF20T only: When switched off, the fan continues to operate for the adjustable timer over- run period.

Condensation Operation

The fan operates at condensation control speed, when the relative humidity exceeds the set level, and turns off when the humidity drops.

Boost Operation

The integral pull cord switch switches the fan to run at high speed. Bottom light “II” is lit when the fan is

operating at high speed. Note: If the separate on/off switch and integral pull cord are both on, the lights “I” and “II” will both be lit and the fan will run at high speed.

Trickle feature on or off

This is set by the installer to provide continuous background extraction, when the humidity level is below that set by adjusting screw “RH”.

LVCF20T only

Time delay stat feature on or off

This is set by the installer to provide a 2-minute time delay start when the fan is switched on using a separate on/off switch.

Cleaning

1.Before cleaning, isolate the fan completely from the mains supply.

2.Only clean the external surface of the fan, using a damp lint free cloth.

3.Do not use strong detergents, solvents or chemical cleaners.

4.Allow the fan to dry thoroughly before use.

5.Apart from cleaning, no other maintenance is required.

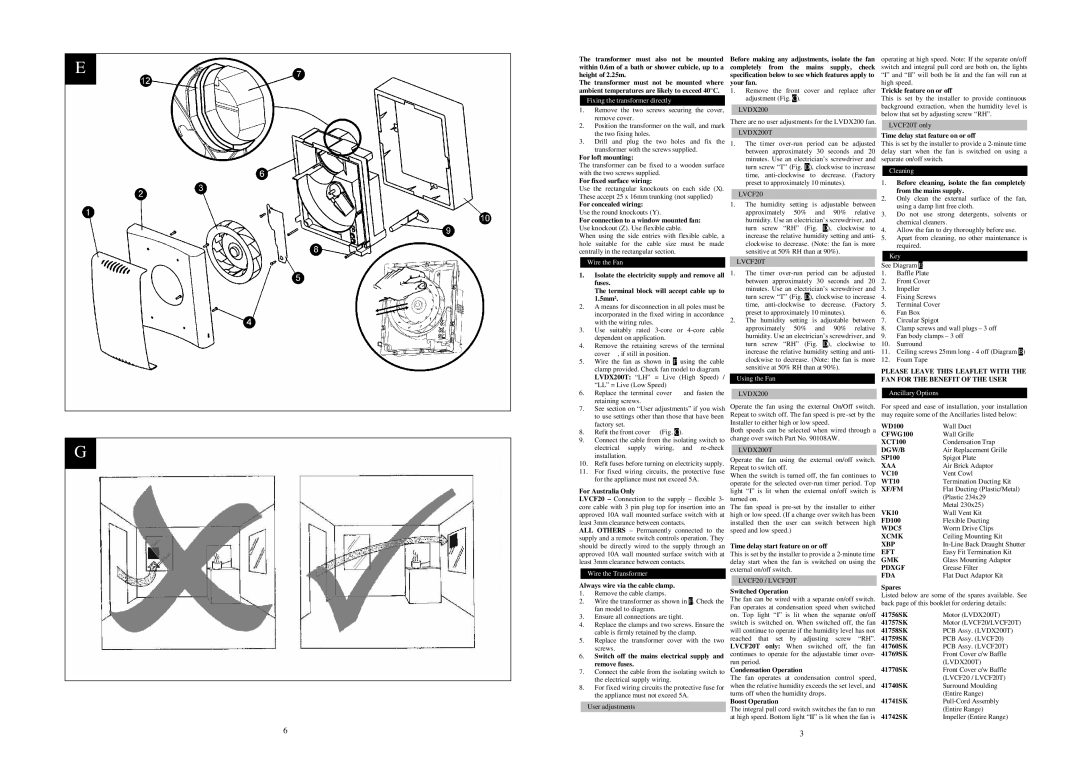

Key

See Diagram

1.Baffle Plate

2.Front Cover

3.Impeller

4.Fixing Screws

5.Terminal Cover

6.Fan Box

7.Circular Spigot

8.Clamp screws and wall plugs – 3 off

9.Fan body clamps – 3 off

10.Surround

11.Ceiling screws 25mm long - 4 off (Diagram  )

)

12.Foam Tape

PLEASE LEAVE THIS LEAFLET WITH THE FAN FOR THE BENEFIT OF THE USER

Ancillary Options

For speed and ease of installation, your installation may require some of the Ancillaries listed below:

WD100 | Wall Duct |

CFWG100 | Wall Grille |

XCT100 | Condensation Trap |

DGW/B | Air Replacement Grille |

SP100 | Spigot Plate |

XAA | Air Brick Adaptor |

VC10 | Vent Cowl |

WT10 | Termination Ducting Kit |

XF/FM | Flat Ducting (Plastic/Metal) |

| (Plastic 234x29 |

VK10 | Metal 230x25) |

Wall Vent Kit |

FD100 | Flexible Ducting |

WDC5 | Worm Drive Clips |

XCMK | Ceiling Mounting Kit |

XBP | In-Line Back Draught Shutter |

EFT | Easy Fit Termination Kit |

GMK | Glass Mounting Adaptor |

PDXGF | Grease Filter |

FDA | Flat Duct Adaptor Kit |

Spares

Listed below are some of the spares available. See back page of this booklet for ordering details:

41756SK | Motor (LVDX200T) |

41757SK | Motor (LVCF20/LVCF20T) |

41758SK | PCB Assy. (LVDX200T) |

41759SK | PCB Assy. (LVCF20) |

41760SK | PCB Assy. (LVCF20T) |

41769SK | Front Cover c/w Baffle |

41770SK | (LVDX200T) |

Front Cover c/w Baffle |

41740SK | (LVCF20 / LVCF20T) |

Surround Moulding |

41741SK | (Entire Range) |

Pull-Cord Assembly |

41742SK | (Entire Range) |

Impeller (Entire Range) |