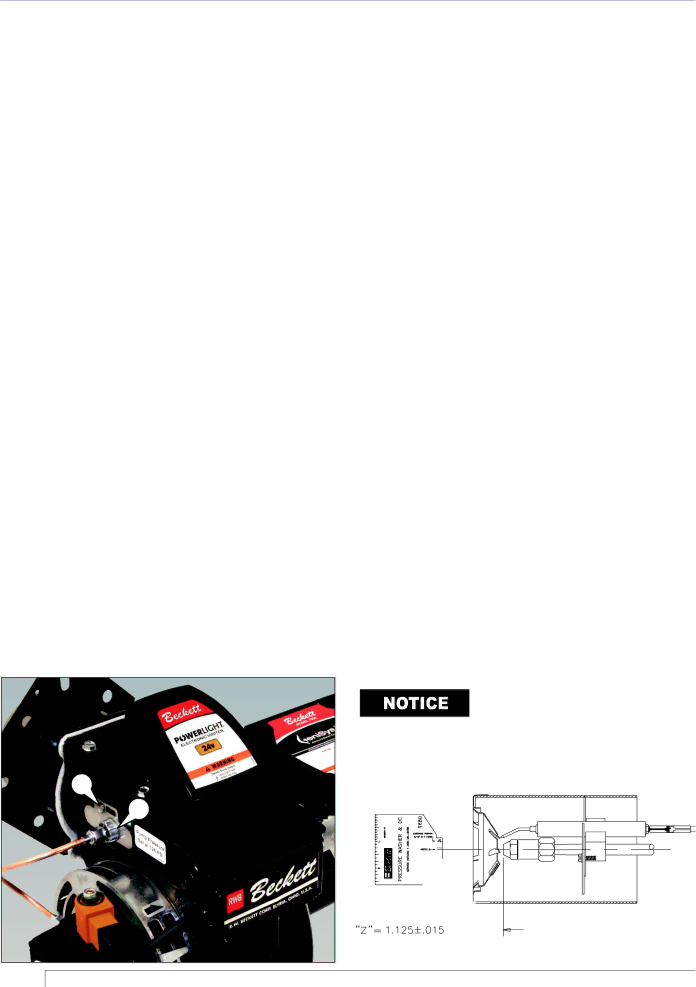

24 VDC specifications

Beckett 24 VDC is a reliable and efficient solution widely utilized in various applications, particularly in heating systems, pumps, and HVAC equipment. This power supply system delivers a stable 24 volts of direct current (VDC), making it suitable for use in both residential and commercial settings. One of its primary advantages is its ability to operate safely in low-voltage environments, significantly reducing the risk of electrical shocks and allowing for more straightforward integration into existing systems.One of the standout features of Beckett 24 VDC is its compact and durable design. The unit is engineered to withstand varying environmental conditions, ensuring that it can function effectively even in challenging settings. This resilience translates to increased reliability and longevity, minimizing the need for frequent replacements or maintenance.

The technology underlying Beckett 24 VDC incorporates advanced circuitry that ensures high efficiency. This efficient operation can lead to reduced energy consumption, making it an eco-friendly choice for those looking to lower their carbon footprint. Furthermore, this technology is designed to provide a constant output voltage, ensuring stable performance regardless of fluctuations in the input voltage.

Another notable characteristic of the Beckett 24 VDC system is its versatility. It can easily be integrated into various applications, from powering controls and sensors to operating pumps and motors. This adaptability makes it a valuable asset for both new installations and retrofitting existing systems.

The installation process for Beckett 24 VDC is designed to be straightforward, featuring clear wiring diagrams and accessible connection points. This ease of installation can save time and labor, making it an attractive option for contractors and technicians alike.

Additionally, the Beckett 24 VDC system is compliant with industry standards, ensuring that it meets regulatory requirements for safety and performance. This compliance provides peace of mind for users and installers, knowing that they are utilizing a product that adheres to the highest standards.

In conclusion, Beckett 24 VDC stands out as a dependable, efficient, and versatile solution for low-voltage applications. Its robust construction, energy-efficient technology, and ease of installation make it an ideal choice for users looking to enhance their systems while prioritizing safety and reliability. Whether in residential or commercial environments, Beckett 24 VDC proves to be a valuable addition to any setup.