CLM-150-S150-GI, CLM-300-W-GI specifications

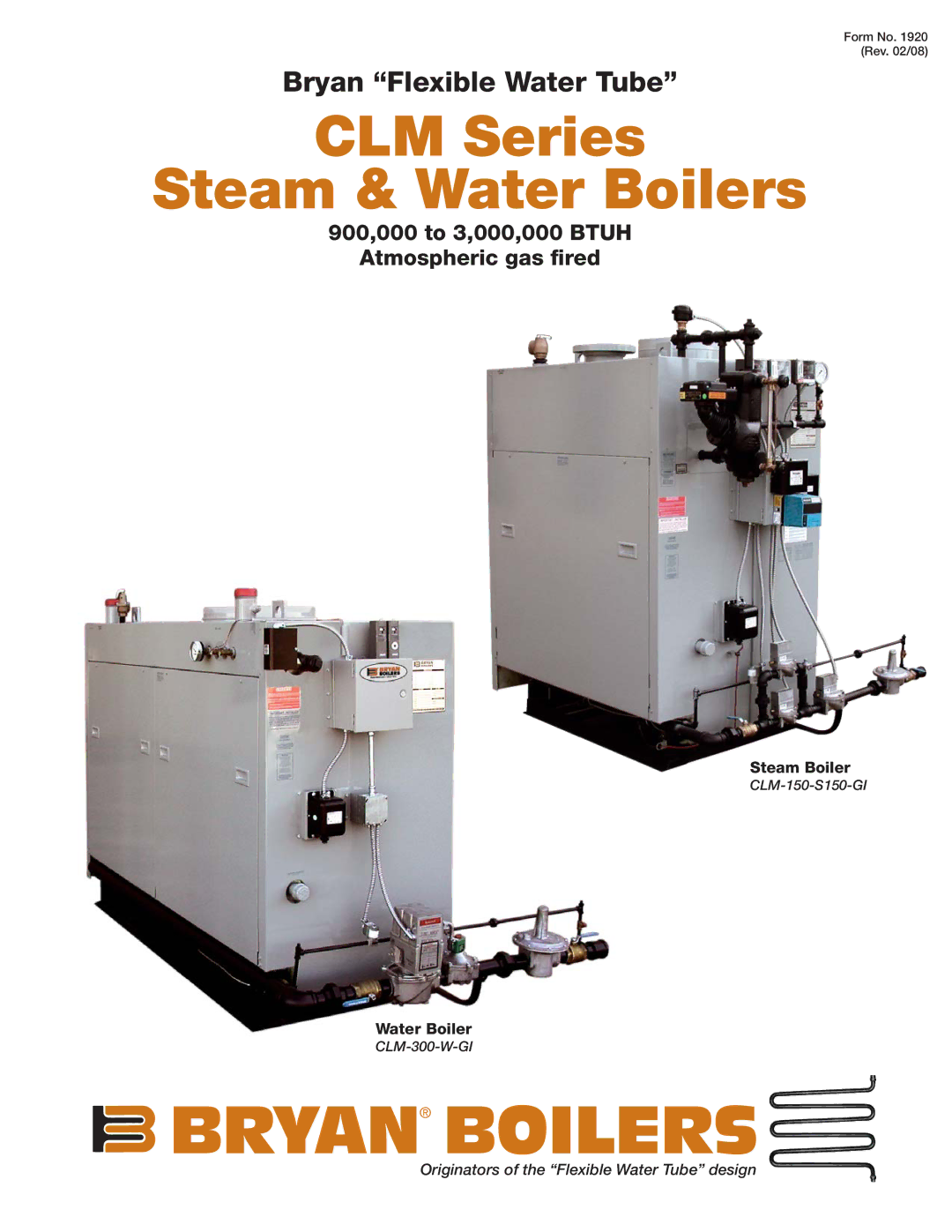

Bryan Boilers is a recognized name in the heating industry, renowned for its innovative approach to steam and hot water generation. Among its impressive lineup are the CLM-300-W-GI and CLM-150-S150-GI models, which showcase the company's commitment to quality, efficiency, and advanced technology.The CLM-300-W-GI is a high-capacity water boiler designed to meet the demanding needs of various applications, including commercial and industrial operations. Its robust construction is complemented by a multitude of innovative features that enhance performance and durability. One of its main features is the direct contact water heater design, enabling superior heat transfer and minimizing energy losses. The boiler is equipped with a high-efficiency burner system that operates with low emissions, making it a green choice for companies looking to reduce their carbon footprint.

On the other hand, the CLM-150-S150-GI model offers a slightly smaller capacity suited for moderate heating requirements. Despite its size, the CLM-150 doesn’t compromise on efficiency or performance. It is designed with a streamlined burner system that ensures high combustion efficiency while maintaining low operational costs. This makes it an ideal choice for businesses seeking to optimize their energy consumption without sacrificing performance.

Both models incorporate advanced technology, including an electronic control system that allows for precise monitoring and management of the heating process. This control system is user-friendly and provides real-time data, enabling operators to make informed decisions about their heating systems. Additionally, both boilers are built with high-quality materials resistant to corrosion and wear, ensuring longevity and reduced maintenance needs.

Another notable feature of both the CLM-300-W-GI and CLM-150-S150-GI is their modular design, allowing for easy installation and flexibility in system configuration. This feature also simplifies maintenance tasks, making it easier to access components for service and repairs.

In summary, Bryan Boilers offers a blend of efficiency, innovation, and reliability in the CLM-300-W-GI and CLM-150-S150-GI models. These boilers are designed to meet the needs of various industries while promoting sustainability with their advanced combustion technologies. With a focus on performance and user-friendly operations, Bryan Boilers continues to set the standard for excellence in the heating sector.