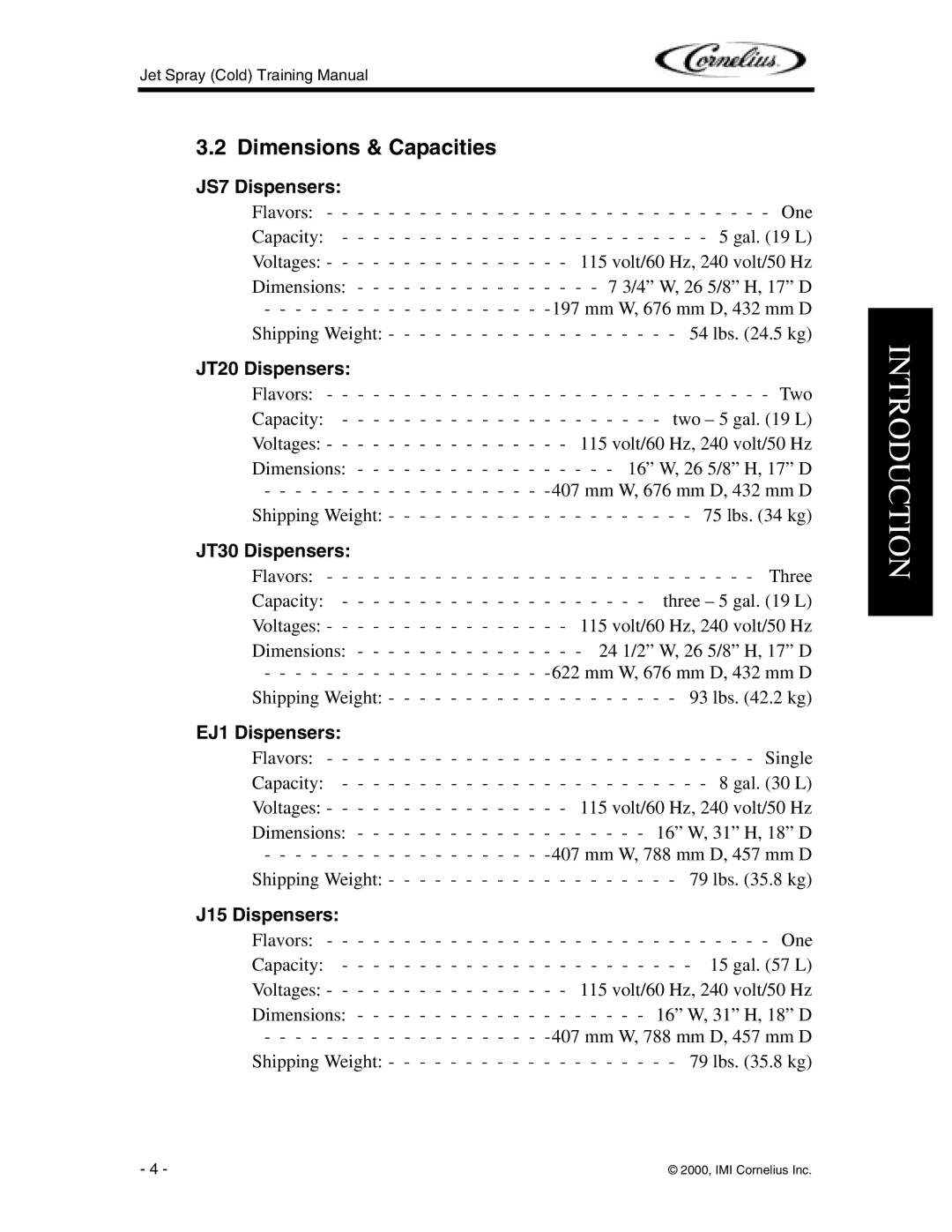

JT30, EJ1, J15, JS7, JT20 specifications

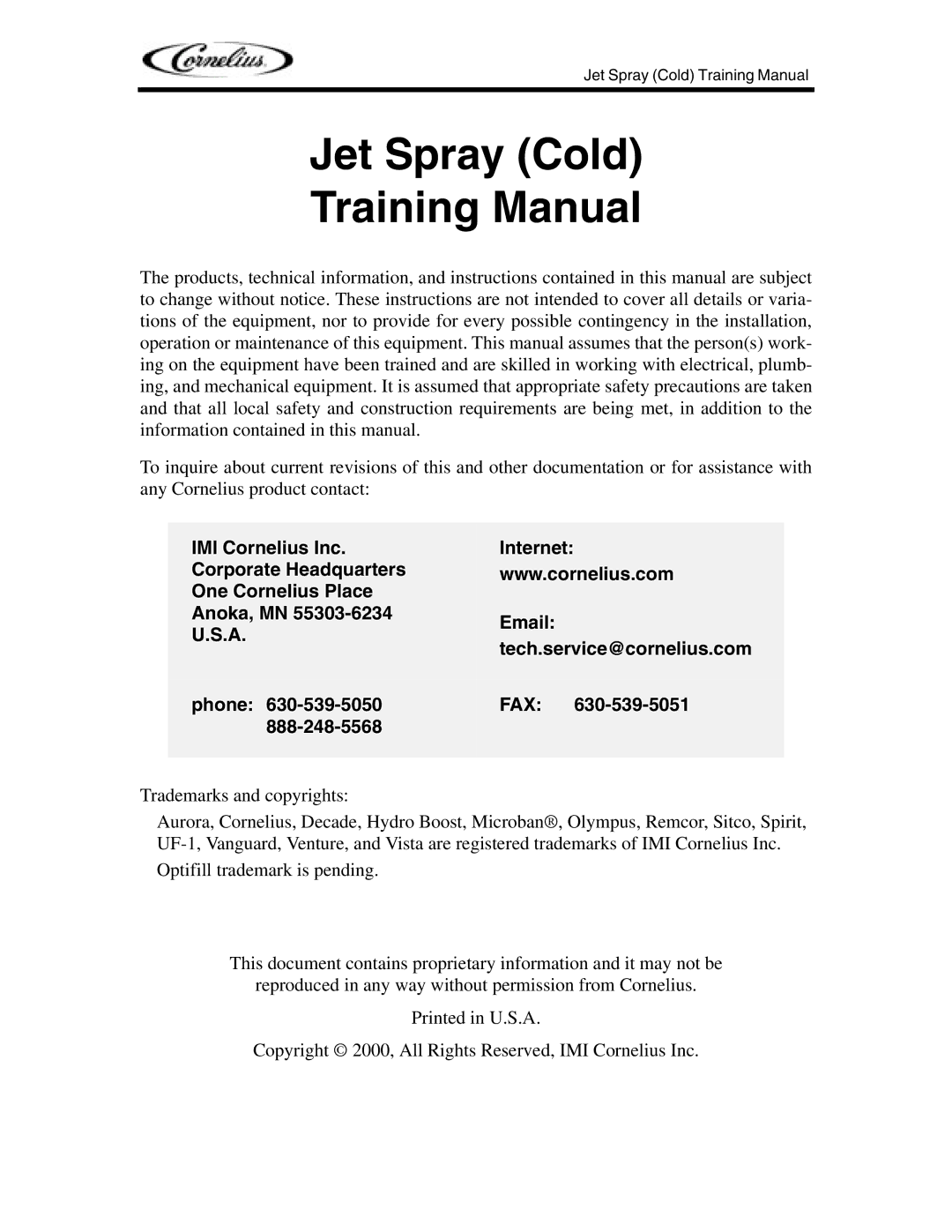

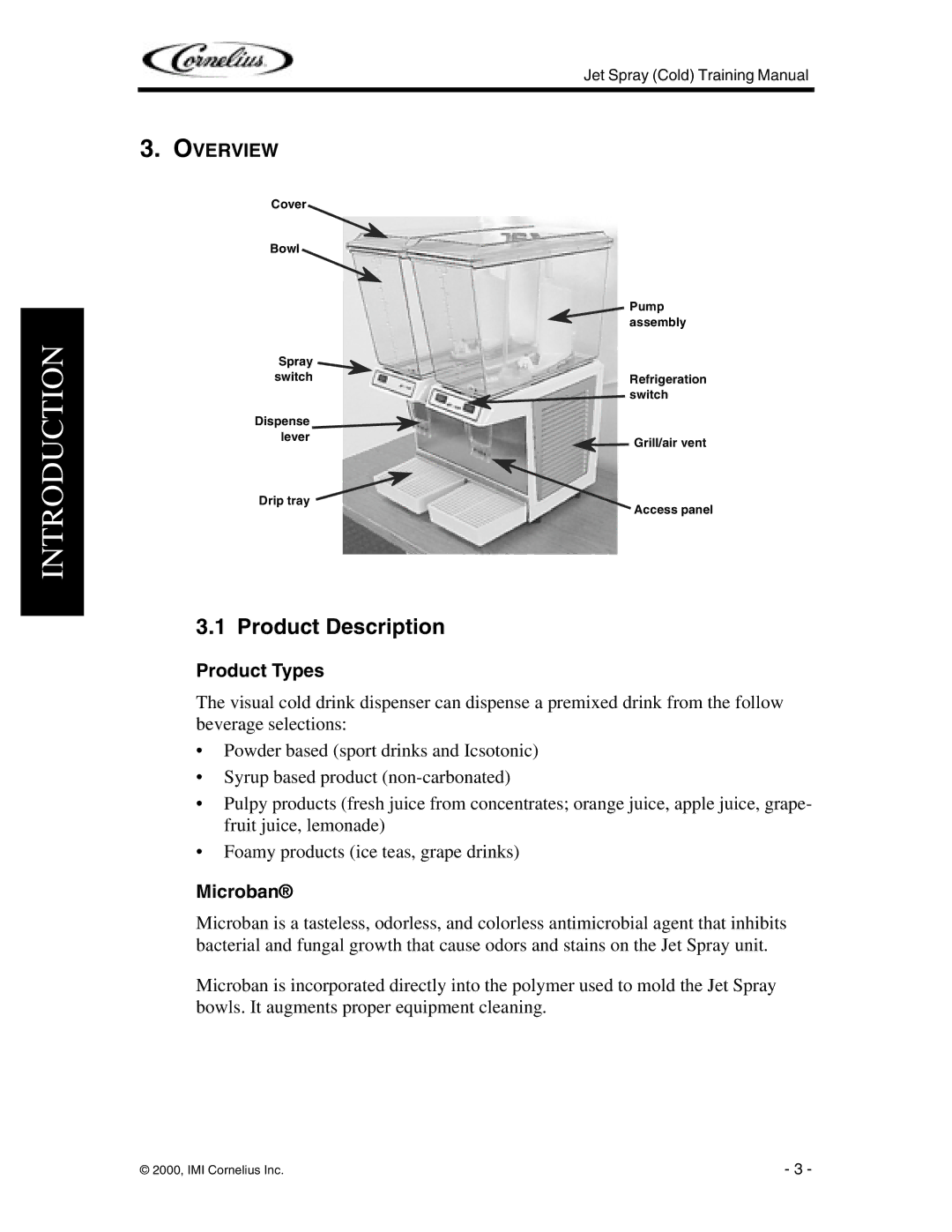

Cornelius has long been a leader in the beverage dispensing industry, with a range of innovative products including the JT20, JS7, J15, EJ1, and JT30 models. Each of these dispensers showcases unique features, advanced technologies, and characteristics that cater to diverse commercial needs.The Cornelius JT20 is known for its versatility and efficiency. Designed for high-volume applications, this unit offers a 20-flavor capability, making it an excellent choice for restaurants and convenience stores. With advanced cooling technology, the JT20 ensures optimal beverage temperature while minimizing energy consumption. Its user-friendly interface allows for easy calibration and operation, which is crucial during busy service hours.

Next is the JS7, which appeals to those who prioritize simplicity and reliability. This model boasts a compact design, ideal for limited spaces while delivering a robust performance. The JS7 comes equipped with high-quality carbonators that enhance drink taste and consistency. Its straightforward maintenance features ensure that operators can keep it running smoothly without excessive downtime.

The J15 model stands out for its innovative integration of digital technology. Equipped with a smart dispensing system, the J15 allows users to customize drinks according to customer preferences with precise measurements. This model's intuitive touchscreen interface enhances user experience while providing essential analytics for operators to optimize beverage offerings.

In contrast, the EJ1 emphasizes eco-friendliness. This model is crafted with sustainable materials and incorporates advanced energy-saving features, making it suitable for environmentally conscious businesses. The EJ1 also supports a variety of drink options, including non-carbonated beverages, further adding to its versatility.

Lastly, the JT30 takes performance to a new level with its impressive output and flexibility to serve a wide range of beverages. It features a specialized cooling system designed for rapid beverage service without sacrificing quality, making it ideal for high-traffic locations. The JT30’s modular design allows for easy customization, ensuring it can be tailored to meet specific business needs.

In summary, the Cornelius JT20, JS7, J15, EJ1, and JT30 each bring unique advantages to the table, combining modern technology, efficiency, and adaptability to the beverage dispensing market. With a commitment to innovation, Cornelius continues to set the standard in the industry, ensuring that operators can deliver exceptional beverage experiences to their customers.