![]() Delfield™®

Delfield™®

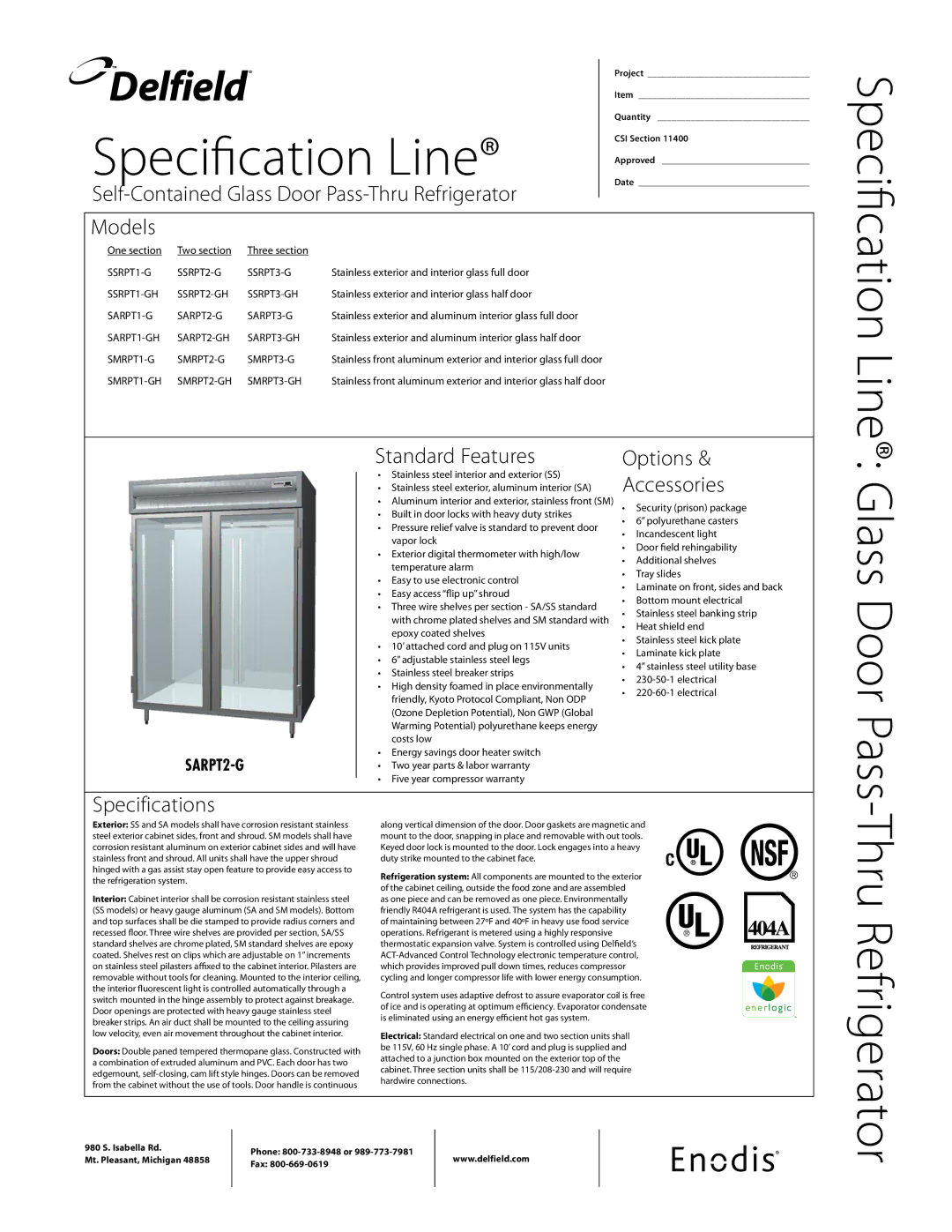

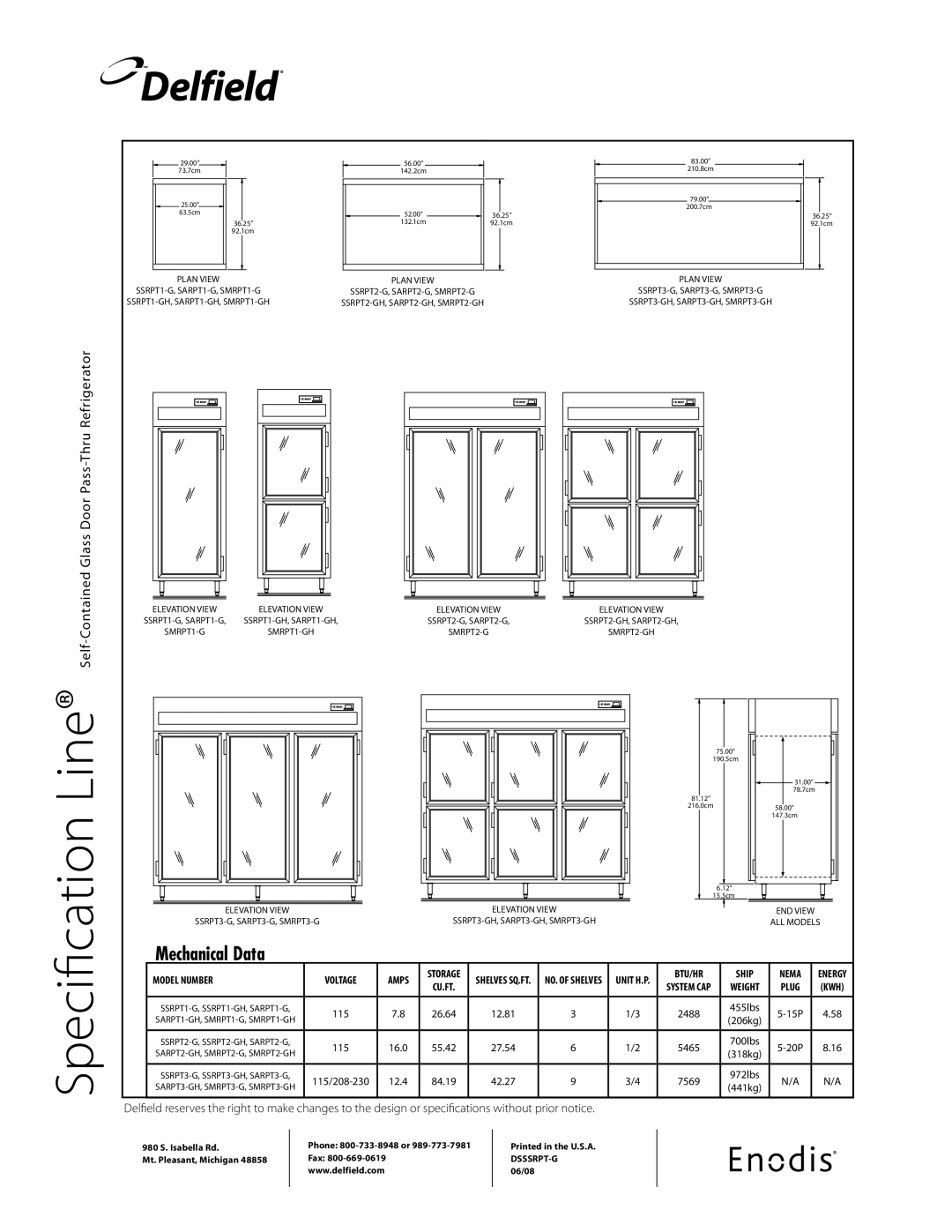

Specification Line®

Self-Contained Glass Door Pass-Thru Refrigerator

Project ___________________________________

Item _____________________________________

Quantity _ ________________________________

CSI Section 11400

Approved _ _______________________________

Date _____________________________________

Specification

Models

One section | Two section | Three section |

|

Stainless exterior and interior glass full door | |||

Stainless exterior and interior glass half door | |||

Stainless exterior and aluminum interior glass full door | |||

Stainless exterior and aluminum interior glass half door | |||

Stainless front aluminum exterior and interior glass full door | |||

Stainless front aluminum exterior and interior glass half door |

| Standard Features | Options & | ||

| • Stainless steel interior and exterior (SS) | Accessories | ||

| ||||

| • | Stainless steel exterior, aluminum interior (SA) | ||

| • | Aluminum interior and exterior, stainless front (SM) | • | Security (prison) package |

| • Built in door locks with heavy duty strikes | • | 6” polyurethane casters | |

| • Pressure relief valve is standard to prevent door | |||

| • | Incandescent light | ||

|

| vapor lock | ||

|

| • | Door field rehingability | |

| • Exterior digital thermometer with high/low | |||

| • | Additional shelves | ||

|

| temperature alarm | ||

|

| • | Tray slides | |

| • Easy to use electronic control | |||

| • Laminate on front, sides and back | |||

| • | Easy access “flip up” shroud | ||

| • | Bottom mount electrical | ||

| • Three wire shelves per section - SA/SS standard | |||

| • Stainless steel banking strip | |||

|

| with chrome plated shelves and SM standard with | ||

|

| • | Heat shield end | |

|

| epoxy coated shelves | ||

|

| • Stainless steel kick plate | ||

| • 10’ attached cord and plug on 115V units | |||

| • | Laminate kick plate | ||

| • 6” adjustable stainless steel legs | |||

| • 4” stainless steel utility base | |||

| • Stainless steel breaker strips | |||

| • | |||

| • High density foamed in place environmentally | |||

| • | |||

|

| friendly, Kyoto Protocol Compliant, Non ODP | ||

|

|

|

| |

|

| (Ozone Depletion Potential), Non GWP (Global |

|

|

|

| Warming Potential) polyurethane keeps energy |

|

|

|

| costs low |

|

|

| • Energy savings door heater switch |

|

| |

• | Two year parts & labor warranty |

|

| |

| • Five year compressor warranty |

|

| |

|

|

| ||

Line®: Glass Door Pass

Specifications

Exterior: SS and SA models shall have corrosion resistant stainless steel exterior cabinet sides, front and shroud. SM models shall have corrosion resistant aluminum on exterior cabinet sides and will have stainless front and shroud. All units shall have the upper shroud hinged with a gas assist stay open feature to provide easy access to the refrigeration system.

Interior: Cabinet interior shall be corrosion resistant stainless steel (SS models) or heavy gauge aluminum (SA and SM models). Bottom and top surfaces shall be die stamped to provide radius corners and recessed floor. Three wire shelves are provided per section, SA/SS standard shelves are chrome plated, SM standard shelves are epoxy coated. Shelves rest on clips which are adjustable on 1” increments on stainless steel pilasters affixed to the cabinet interior. Pilasters are removable without tools for cleaning. Mounted to the interior ceiling, the interior fluorescent light is controlled automatically through a switch mounted in the hinge assembly to protect against breakage. Door openings are protected with heavy gauge stainless steel breaker strips. An air duct shall be mounted to the ceiling assuring low velocity, even air movement throughout the cabinet interior.

Doors: Double paned tempered thermopane glass. Constructed with a combination of extruded aluminum and PVC. Each door has two edgemount,

along vertical dimension of the door. Door gaskets are magnetic and mount to the door, snapping in place and removable with out tools. Keyed door lock is mounted to the door. Lock engages into a heavy duty strike mounted to the cabinet face.

Refrigeration system: All components are mounted to the exterior of the cabinet ceiling, outside the food zone and are assembled

as one piece and can be removed as one piece. Environmentally friendly R404A refrigerant is used. The system has the capability of maintaining between 27ºF and 40ºF in heavy use food service operations. Refrigerant is metered using a highly responsive thermostatic expansion valve. System is controlled using Delfield’s

Control system uses adaptive defrost to assure evaporator coil is free of ice and is operating at optimum efficiency. Evaporator condensate is eliminated using an energy efficient hot gas system.

Electrical: Standard electrical on one and two section units shall be 115V, 60 Hz single phase. A 10’ cord and plug is supplied and attached to a junction box mounted on the exterior top of the cabinet. Three section units shall be

980 S. Isabella Rd. | Phone: | www.delfield.com | |

Mt. Pleasant, Michigan 48858 | |||

Fax: | |||

|

|