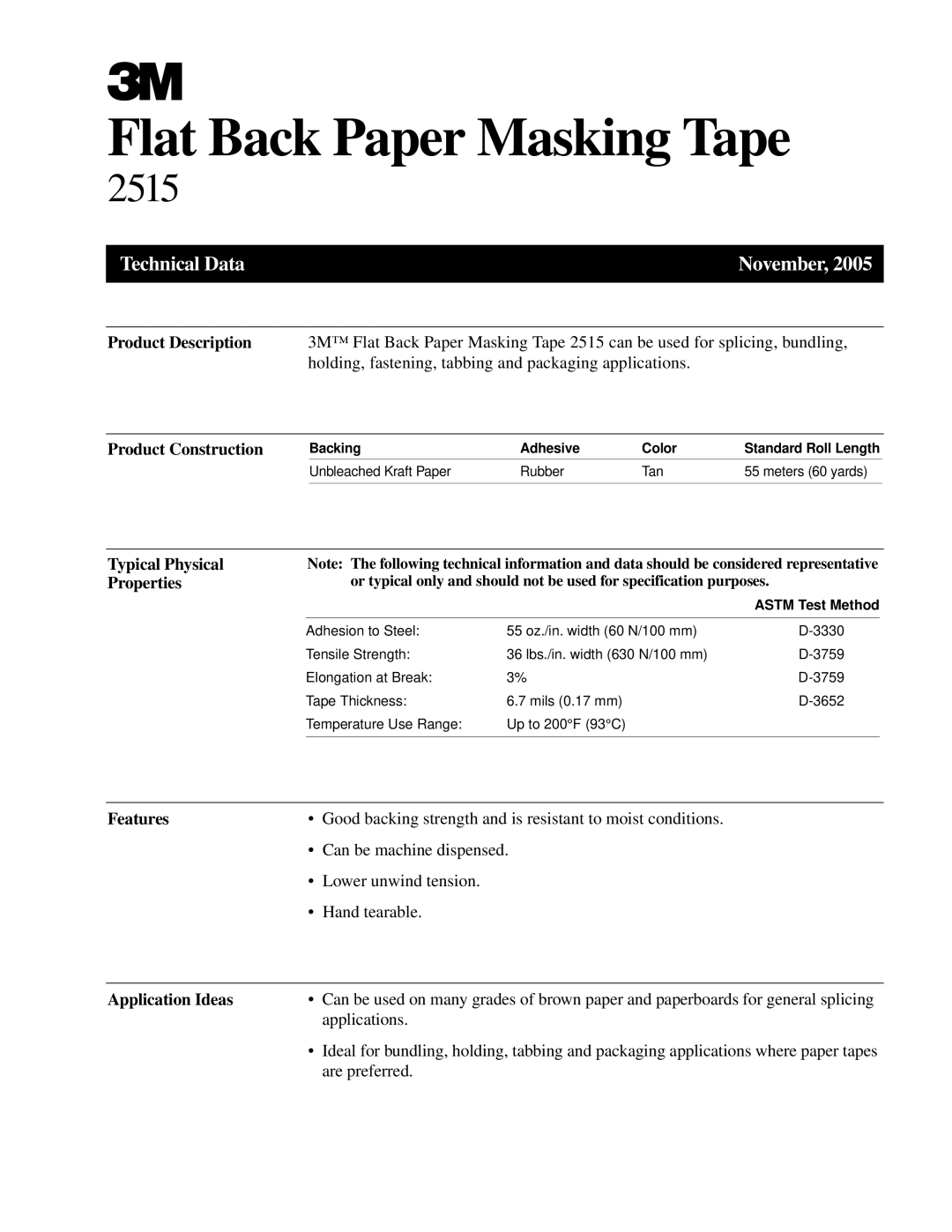

2515 specifications

The 3M 2515 is a high-performance masking tape that is widely regarded in both industrial and creative settings for its versatility and reliability. Designed primarily for painting and surface protection, this tape offers unique characteristics that make it a favorite among professionals and DIY enthusiasts alike.One of the standout features of the 3M 2515 is its ability to adhere securely to a variety of surfaces, including wood, metal, and glass. The strong adhesion ensures that the tape stays in place during application, preventing any bleed-through of paint or other materials while also providing clean lines and an immaculate finish. This makes the 3M 2515 particularly useful in achieving sharp paint edges when used in conjunction with spray or brush applications.

The tape is also designed to withstand a range of environmental conditions. Its durability is complemented by a temperature resistance of up to 250°F (121°C) for up to 30 minutes, making it suitable for both indoor and outdoor use. This feature is particularly beneficial for projects that may require exposure to heat or fluctuating temperatures.

Another notable characteristic of the 3M 2515 is its ease of removal. The tape can be peeled off cleanly without leaving any adhesive residue behind, which is crucial for maintaining the integrity of surfaces and ensuring that they remain ready for subsequent treatment or finishing touches. This characteristic also allows for adjustments during the application process, as the tape can be repositioned without damaging the underlying surface.

The technology behind the 3M 2515 focuses on advanced adhesion science, ensuring that the tape can deliver consistent performance across various applications. The specially formulated backing and adhesive layers contribute to its high tensile strength and resistance to tearing, providing users with confidence in their application.

Whether used for bodywork, trim applications, or creating intricate designs, the 3M 2515 stands out for its performance and versatility. With its combination of strong adhesion, temperature resistance, and clean removal, it has established itself as a reliable choice for anyone looking to achieve professional-quality results in their projects. Overall, the 3M 2515 is a valuable tool that helps users tackle challenging tasks with ease, making it an essential addition to any toolkit.