Contents

Unpacking

Remove the components from the box. Inspect for concealed damage and/or missing items. If you discover any damage and/or missing pieces, contact your distributor immediately.

Your 3M™ Series

•3M™ Series 05 Spray Gun

•Cup

•Care Kit

3M™ Series

General Set Up and Spray Gun Use

For additional instructions refer to your cup or fluid source manual.

Note: Flush the spray gun before using

The 3M™ Series

3M™ Series

The 3M™ Series

*Maximum inlet pressure will yield approximately 10 psi at the air cap.

Air Regulation

The 3M™ Series

The regulator adjustment knob on the 3M™ Series

Adjusting Fluid Flow

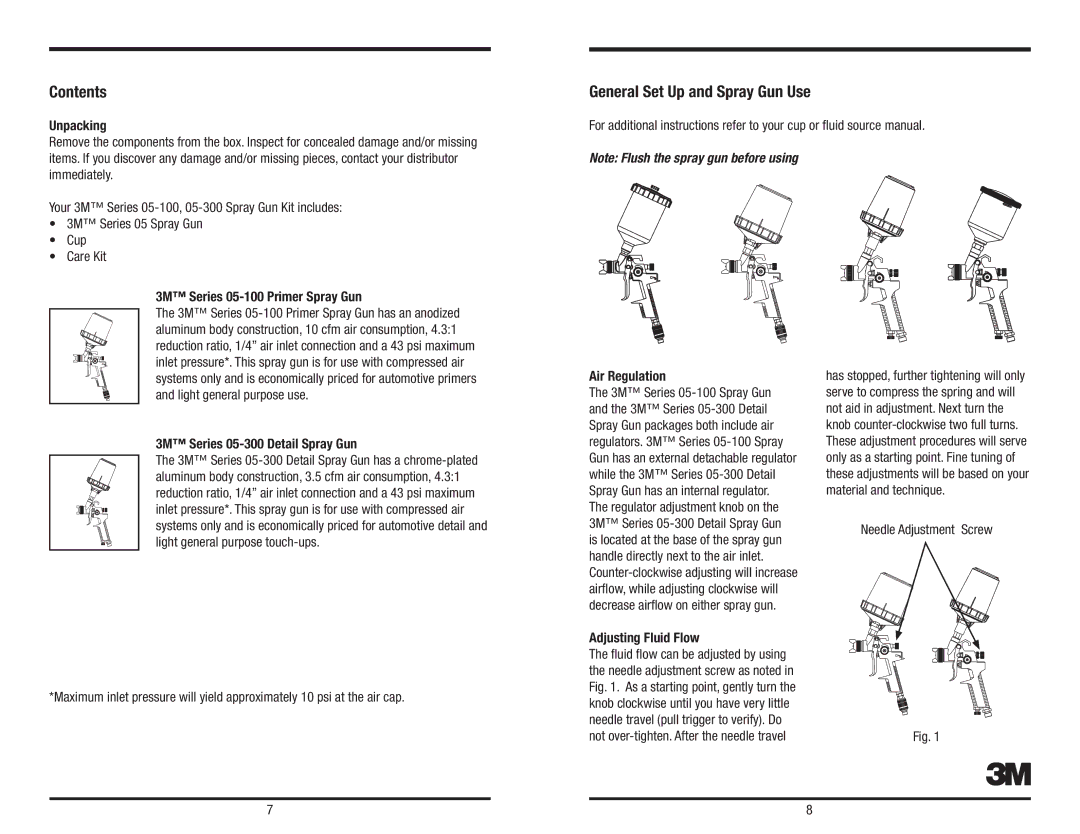

The fluid flow can be adjusted by using the needle adjustment screw as noted in Fig. 1. As a starting point, gently turn the knob clockwise until you have very little needle travel (pull trigger to verify). Do not

has stopped, further tightening will only serve to compress the spring and will not aid in adjustment. Next turn the knob

Needle Adjustment Screw

Fig. 1

3

7 | 8 |