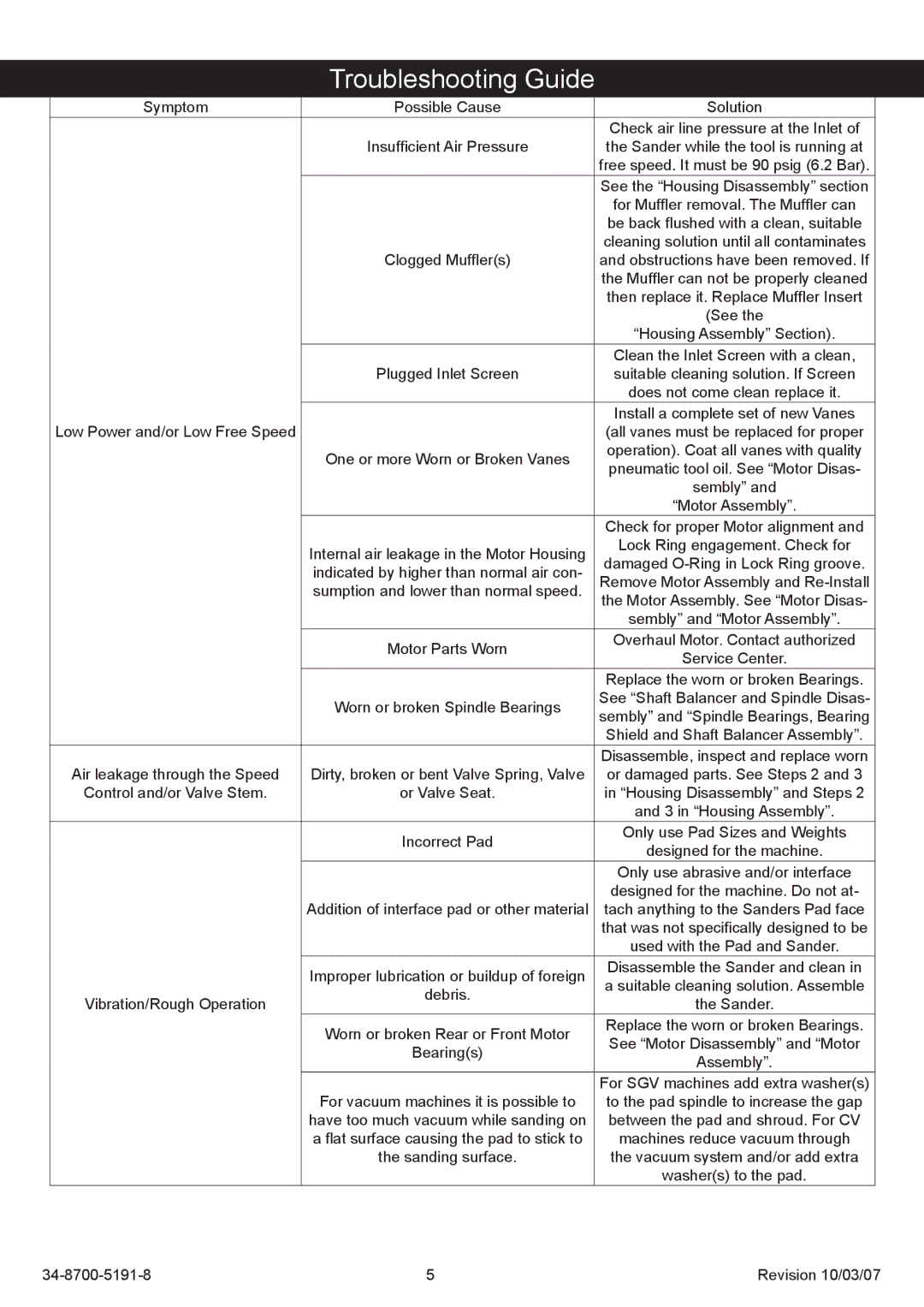

Troubleshooting Guide

Symptom | Possible Cause | Solution | |

|

| Check air line pressure at the Inlet of | |

| Insufficient Air Pressure | the Sander while the tool is running at | |

|

| free speed. It must be 90 psig (6.2 Bar). | |

|

| See the “Housing Disassembly” section | |

|

| for Muffler removal. The Muffler can | |

|

| be back flushed with a clean, suitable | |

|

| cleaning solution until all contaminates | |

| Clogged Muffler(s) | and obstructions have been removed. If | |

|

| the Muffler can not be properly cleaned | |

|

| then replace it. Replace Muffler Insert | |

|

| (See the | |

|

| “Housing Assembly” Section). | |

|

| Clean the Inlet Screen with a clean, | |

| Plugged Inlet Screen | suitable cleaning solution. If Screen | |

|

| does not come clean replace it. | |

|

| Install a complete set of new Vanes | |

Low Power and/or Low Free Speed |

| (all vanes must be replaced for proper | |

| One or more Worn or Broken Vanes | operation). Coat all vanes with quality | |

| pneumatic tool oil. See “Motor Disas- | ||

|

| ||

|

| sembly” and | |

|

| “Motor Assembly”. | |

|

| Check for proper Motor alignment and | |

| Internal air leakage in the Motor Housing | Lock Ring engagement. Check for | |

| damaged | ||

| indicated by higher than normal air con- | ||

| Remove Motor Assembly and | ||

| sumption and lower than normal speed. | ||

| the Motor Assembly. See “Motor Disas- | ||

|

| ||

|

| sembly” and “Motor Assembly”. | |

| Motor Parts Worn | Overhaul Motor. Contact authorized | |

| Service Center. | ||

|

| ||

|

| Replace the worn or broken Bearings. | |

| Worn or broken Spindle Bearings | See “Shaft Balancer and Spindle Disas- | |

| sembly” and “Spindle Bearings, Bearing | ||

|

| ||

|

| Shield and Shaft Balancer Assembly”. | |

|

| Disassemble, inspect and replace worn | |

Air leakage through the Speed | Dirty, broken or bent Valve Spring, Valve | or damaged parts. See Steps 2 and 3 | |

Control and/or Valve Stem. | or Valve Seat. | in “Housing Disassembly” and Steps 2 | |

|

| and 3 in “Housing Assembly”. | |

| Incorrect Pad | Only use Pad Sizes and Weights | |

| designed for the machine. | ||

|

| ||

|

| Only use abrasive and/or interface | |

|

| designed for the machine. Do not at- | |

| Addition of interface pad or other material | tach anything to the Sanders Pad face | |

|

| that was not specifically designed to be | |

|

| used with the Pad and Sander. | |

| Improper lubrication or buildup of foreign | Disassemble the Sander and clean in | |

| a suitable cleaning solution. Assemble | ||

| debris. | ||

Vibration/Rough Operation | the Sander. | ||

| |||

| Worn or broken Rear or Front Motor | Replace the worn or broken Bearings. | |

| See “Motor Disassembly” and “Motor | ||

| Bearing(s) | ||

| Assembly”. | ||

|

| ||

|

| For SGV machines add extra washer(s) | |

| For vacuum machines it is possible to | to the pad spindle to increase the gap | |

| have too much vacuum while sanding on | between the pad and shroud. For CV | |

| a flat surface causing the pad to stick to | machines reduce vacuum through | |

| the sanding surface. | the vacuum system and/or add extra | |

|

| washer(s) to the pad. |

Revision 10/03/07 |