CONFINED SPACE

When drawing combustion and dilution air from inside a conventionally constructed building to a confined space, such a space shall be provided with two permanent openings, ONE IN OR WITHIN 12 INCHES (30.5cm) OF THE ENCLOSURE BOTTOM. Each opening shall have a free area of at least one square inch per 1000 Btuh (2,225mm2/Kw)of the total input of all appliances in the enclosure, but not less than 100 square inches (645 square cm).

If the confined space is within a building of tight construction, air for combustion, ventilation and draft hood dilution must be obtained from outdoors. When directly communicating with the outdoors or communicating with the outdoors through vertical ducts, two permanent openings, located in the above manner, shall be provided. Each opening shall have a free area of not less than one square inch per 4000 Btuh (8,900mm2/Kw) of the total input of all appliances in the enclosure. If horizontal ducts are used, each opening shall have a free area of not less than one square inch per 2000 Btuh (4,450mm2/Kw) of the total input of all appliances in the enclosure. For Canadian installations consult CAN/CGA B149.

Where an exhaust fan is installed in the same room with a heater, sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN INTO THE ROOM THROUGH THE CHIMNEY, CAUSING POOR COMBUSTION. SOOTING MAY RESULT AND RISK OF ASPHYXIATION WILL OCCUR.

VENTING

WARNING

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING THE HEATER MUST BE FOLLOWED TO AVOID CHOKED COMBUSTION OR RECIRCULATION OF FLUE GASES. SUCH CONDITIONS CAUSE SOOTING OR RISKS OF FIRE AND ASPHYXIATION.

In the United States:

Vent sizing, installation and termination shall be in accordance with the NATIONAL FUEL GAS CODE. ANSI Z223.1-1999 or most recent edition.

In Canada:

With Canadian Installation Code CAN/CGA B149 (latest edition) Type B venting may be used with these heaters. All local and utility regulations on venting should be followed.

Remove all soot or other obstructions from chimney which will retard free draft.

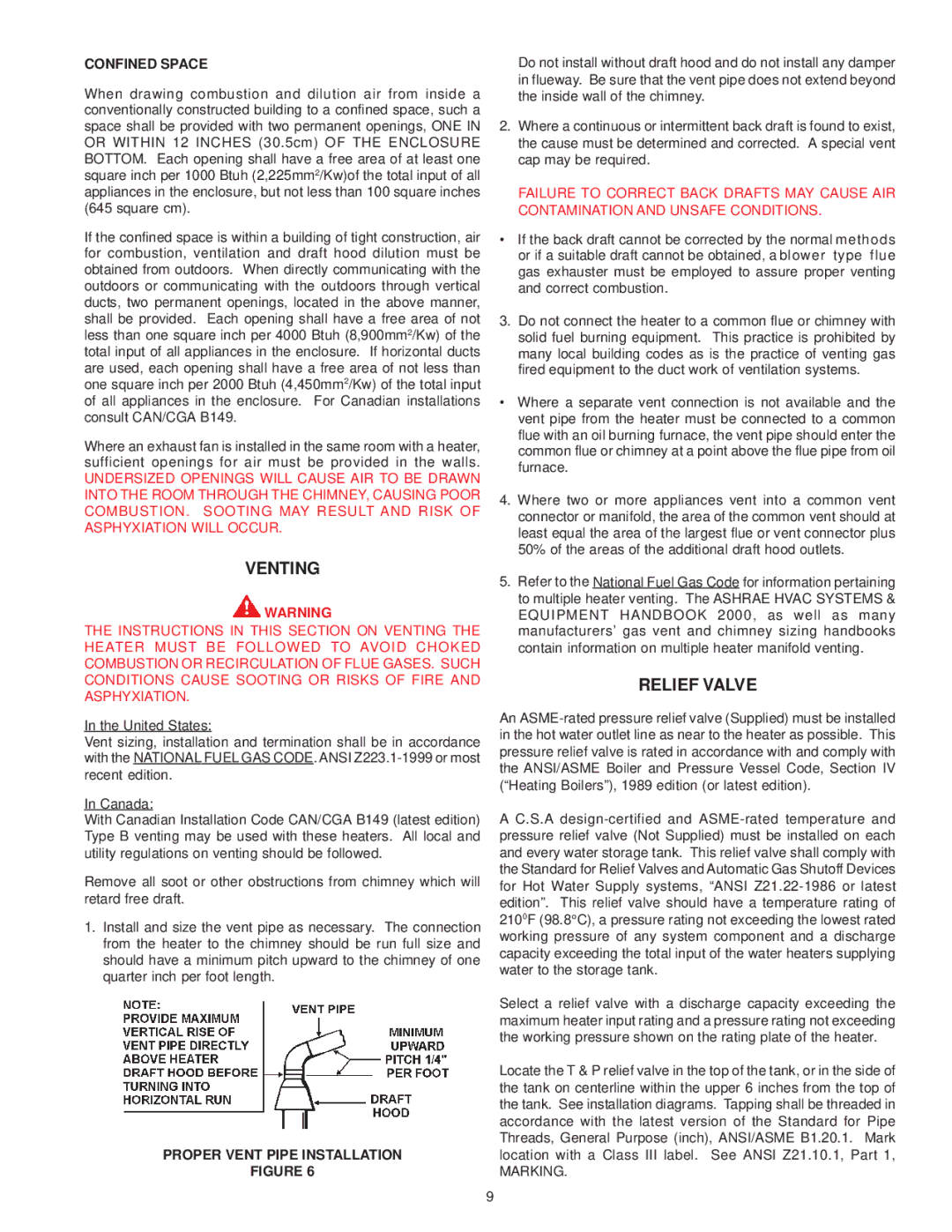

1.Install and size the vent pipe as necessary. The connection from the heater to the chimney should be run full size and should have a minimum pitch upward to the chimney of one quarter inch per foot length.

PROPER VENT PIPE INSTALLATION

FIGURE 6

Do not install without draft hood and do not install any damper in flueway. Be sure that the vent pipe does not extend beyond the inside wall of the chimney.

2.Where a continuous or intermittent back draft is found to exist, the cause must be determined and corrected. A special vent cap may be required.

FAILURE TO CORRECT BACK DRAFTS MAY CAUSE AIR CONTAMINATION AND UNSAFE CONDITIONS.

•If the back draft cannot be corrected by the normal methods or if a suitable draft cannot be obtained, ablower type flue gas exhauster must be employed to assure proper venting and correct combustion.

3.Do not connect the heater to a common flue or chimney with solid fuel burning equipment. This practice is prohibited by many local building codes as is the practice of venting gas fired equipment to the duct work of ventilation systems.

•Where a separate vent connection is not available and the vent pipe from the heater must be connected to a common flue with an oil burning furnace, the vent pipe should enter the common flue or chimney at a point above the flue pipe from oil furnace.

4.Where two or more appliances vent into a common vent connector or manifold, the area of the common vent should at least equal the area of the largest flue or vent connector plus 50% of the areas of the additional draft hood outlets.

5.Refer to the National Fuel Gas Code for information pertaining to multiple heater venting. The ASHRAE HVAC SYSTEMS & EQUIPMENT HANDBOOK 2000, as well as many manufacturers’ gas vent and chimney sizing handbooks contain information on multiple heater manifold venting.

RELIEF VALVE

An ASME-rated pressure relief valve (Supplied) must be installed in the hot water outlet line as near to the heater as possible. This pressure relief valve is rated in accordance with and comply with the ANSI/ASME Boiler and Pressure Vessel Code, Section IV (“Heating Boilers”), 1989 edition (or latest edition).

AC.S.A design-certified and ASME-rated temperature and pressure relief valve (Not Supplied) must be installed on each and every water storage tank. This relief valve shall comply with the Standard for Relief Valves and Automatic Gas Shutoff Devices for Hot Water Supply systems, “ANSI Z21.22-1986 or latest edition”. This relief valve should have a temperature rating of 2100F (98.8°C), a pressure rating not exceeding the lowest rated working pressure of any system component and a discharge capacity exceeding the total input of the water heaters supplying water to the storage tank.

Select a relief valve with a discharge capacity exceeding the maximum heater input rating and a pressure rating not exceeding the working pressure shown on the rating plate of the heater.

Locate the T & P relief valve in the top of the tank, or in the side of the tank on centerline within the upper 6 inches from the top of the tank. See installation diagrams. Tapping shall be threaded in accordance with the latest version of the Standard for Pipe Threads, General Purpose (inch), ANSI/ASME B1.20.1. Mark location with a Class III label. See ANSI Z21.10.1, Part 1,

MARKING.