![]() CAUTION

CAUTION

THE WATER HEATER IS POLARITY SENSITIVE. BEFORE APPLYING ELECTRICITY TO THIS HEATER BE CERTAIN THAT SUPPLY NEUTRAL WIRE TO GROUND CHECK INDICATES ZERO VOLTAGE.

HOT SURFACE IGNITER

The Hot Surface Igniter is a device that ignites the main burner by high temperature (>1800°F or >982°C). When 120VAC is applied to the igniter, sufficient heat is generated to ignite the main burner. Although improvements have been made to strengthen the igniter, it is fragile and care must be taken when handling the igniter to prevent breakage.

GAS PIPING

Contact your local gas service company to ensure that adequate gas service is available and to review applicable installation codes for your area.

Size the main gas line in accordance with Table 3. The figures shown are for straight lengths of pipe at 0.5 in. W.C. (125Pa) pressure drop, which is considered normal for low pressure systems Note that fittings such as elbows and tees will add to the pipe pressure drop.

![]() CAUTION

CAUTION

DO NOT USE FLEXIBLE GAS PIPING.

TABLE 3. MAXIMUM CAPACITY OF PIPE IN CUBIC FEET OF GAS PER HOUR (Based upon a Pressure Drop of 0.5 inch Water Column and 0.6 Specific Gravity Gas and max. gas pressure of 0.5 psig).

| LENGTH |

| NORMAL IRON PIPE SIZES (INCHES) |

| |||

| IN |

| INPUT IN THOUSANDS BTU/HR |

| |||

| FEET | 1 1/4" | 1 1/2" | 2" | 2 1/2" | 3" | 4" |

10 | 1400 | 2100 | 3960 | 6300 | 11000 | 23000 | |

20 | 950 | 1460 | 2750 | 4360 | 7700 | 15800 | |

| 30 | 770 | 1180 | 2200 | 3520 | 6250 | 12800 |

40 | 660 | 990 | 1900 | 3000 | 5300 | 10900 | |

| 50 | 580 | 900 | 1680 | 2650 | 4750 | 9700 |

60 | 530 | 810 | 1520 | 2400 | 4300 | 8800 | |

| 70 | 490 | 750 | 1400 | 2250 | 3900 | 8100 |

| 80 | 460 | 690 | 1300 | 2050 | 3700 | 7500 |

90 | 430 | 650 | 1220 | 1950 | 3450 | 7200 | |

100 | 400 | 620 | 1150 | 1850 | 3250 | 6700 | |

125 | 360 | 550 | 1020 | 1650 | 2950 | 6000 | |

150 | 325 | 500 | 950 | 1500 | 2650 | 5500 | |

| 175 | 300 | 460 | 850 | 1370 | 2450 | 5000 |

200 |

| 430 | 800 | 1280 | 2280 | 4600 | |

LENGTH |

| NORMAL IRON PIPE SIZES (INCHES) |

| |||

IN |

|

| INPUT IN KW |

|

| |

METERS | 1 1/4" | 1 1/2" | 2" | 2 1/2" | 3" | 4" |

3.0 | 410 | 615 | 1160 | 1845 | 3221 | 6735 |

6.1 | 278 | 428 | 805 | 1277 | 2255 | 4626 |

9.1 | 225 | 346 | 644 | 1031 | 1830 | 3748 |

12.2 | 193 | 290 | 556 | 878 | 1552 | 3192 |

15.2 | 170 | 264 | 492 | 776 | 1391 | 2840 |

18.3 | 155 | 237 | 445 | 703 | 1259 | 2577 |

21.3 | 143 | 220 | 410 | 659 | 1142 | 2372 |

24.4 | 135 | 202 | 381 | 600 | 1083 | 2196 |

27.4 | 126 | 190 | 357 | 571 | 1010 | 2108 |

30.5 | 117 | 182 | 337 | 542 | 952 | 1962 |

38.1 | 105 | 161 | 299 | 483 | 864 | 1757 |

45.7 | 95 | 146 | 278 | 439 | 776 | 1610 |

53.3 | 88 | 135 | 249 | 401 | 717 | 1464 |

61.0 |

| 126 | 234 | 375 | 688 | 1347 |

![]() WARNING

WARNING

THE HEATER IS NOT INTENDED FOR OPERATION AT HIGHER THAN 11.0" WATER COLUMN (2.74 Kpa) FOR NATURAL GAS AND 14.0" W.C. (3.49kPa) FOR PROPANE GAS SUPPLY PRESSURE. HIGHER GAS SUPPLY PRESSURES REQUIRE SUPPLEMENTAL REDUCING SERVICE REGULATION. EXPOSURE TO HIGHER GAS SUPPLY PRESSURE MAY CAUSE DAMAGE TO THE GAS CONTROLS WHICH COULD RESULT IN FIRE OR EXPLOSION. IF OVERPRESSURE HAS OCCURRED SUCH AS THROUGH IMPROPER TESTING OF GAS LINES OR EMERGENCY MALFUNCTION OF THE SUPPLY SYSTEM THE GAS VALVE MUST BE CHECKED FOR SAFE OPERATION. MAKE SURE THAT THE OUTSIDE VENTS ON THE SUPPLY REGULATORS AND THE SAFETY VENT VALVES ARE PROTECTED AGAINST BLOCKAGE. THESE ARE PARTS OF THE GAS SUPPLY SYSTEM, NOT THE HEATER. VENT BLOCKAGE MAY OCCUR DURING ICE STORMS. IT IS IMPORTANT TO GUARD AGAINST GAS VALVE FOULING FROM CONTAMINANTS IN THE GAS WAYS. SUCH FOULING MAY CAUSE IMPROPER OPERATION, FIRE OR EXPLOSION.

IF COPPER SUPPLY LINES ARE USED THEY MUST BE INTERNALLY TINNED AND CERTIFIED FOR GAS SERVICE.

BEFORE ATTACHING THE GAS LINE BE SURE THAT ALL GAS PIPE IS CLEAN ON THE INSIDE.

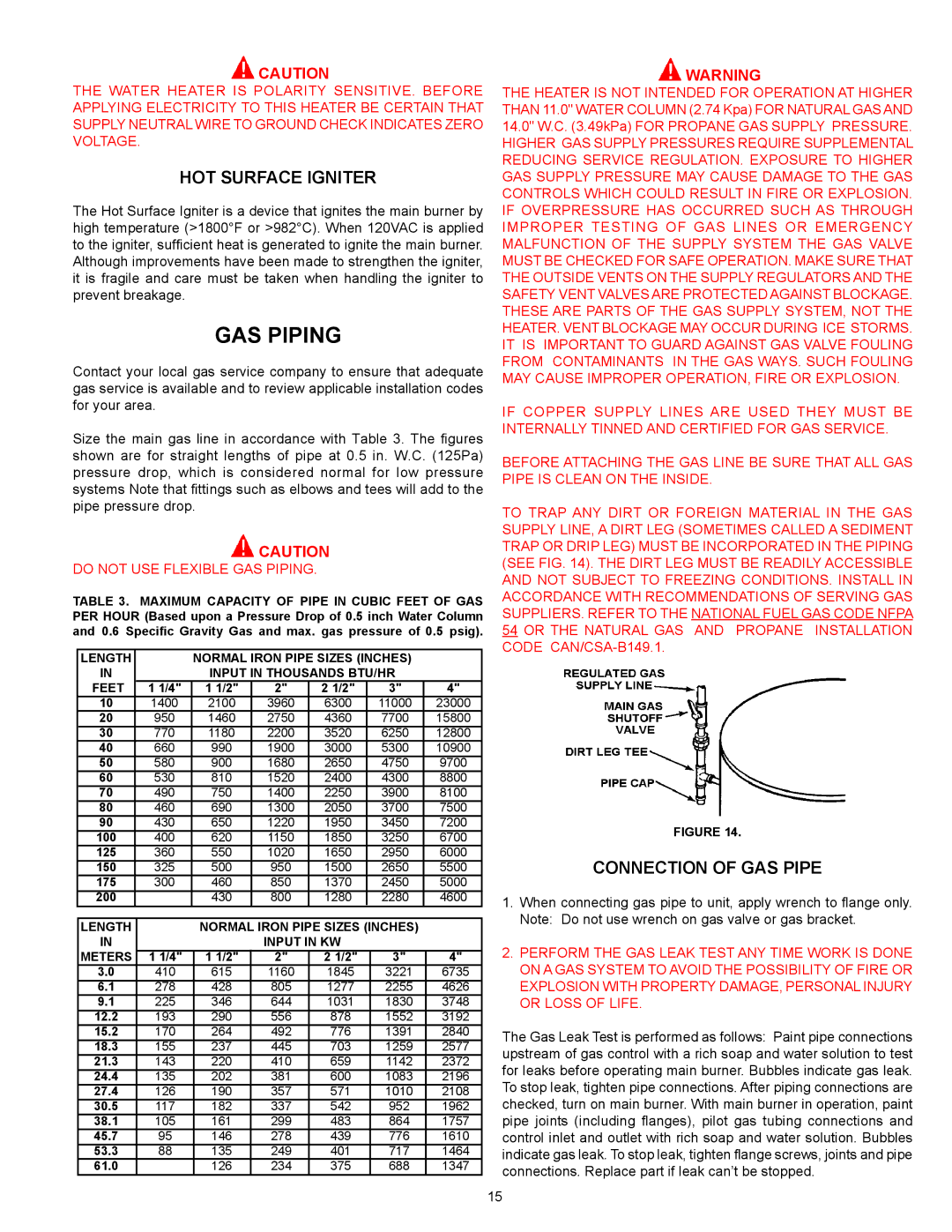

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS SUPPLY LINE, A DIRT LEG (SOMETIMES CALLED A SEDIMENT TRAP OR DRIP LEG) MUST BE INCORPORATED IN THE PIPING (SEE FIG. 14). THE DIRT LEG MUST BE READILY ACCESSIBLE AND NOT SUBJECT TO FREEZING CONDITIONS. INSTALL IN ACCORDANCE WITH RECOMMENDATIONS OF SERVING GAS SUPPLIERS. REFER TO THE NATIONAL FUEL GAS CODE NFPA

54OR THE NATURAL GAS AND PROPANE INSTALLATION

CODE

FIGURE 14.

CONNECTION OF GAS PIPE

1.When connecting gas pipe to unit, apply wrench to flange only. Note: Do not use wrench on gas valve or gas bracket.

2.PERFORM THE GAS LEAK TEST ANY TIME WORK IS DONE

ON A GAS SYSTEM TO AVOID THE POSSIBILITY OF FIRE OR

EXPLOSION WITH PROPERTY DAMAGE, PERSONAL INJURY

OR LOSS OF LIFE.

The Gas Leak Test is performed as follows: Paint pipe connections upstream of gas control with a rich soap and water solution to test for leaks before operating main burner. Bubbles indicate gas leak. To stop leak, tighten pipe connections. After piping connections are checked, turn on main burner. With main burner in operation, paint pipe joints (including flanges), pilot gas tubing connections and control inlet and outlet with rich soap and water solution. Bubbles indicate gas leak. To stop leak, tighten flange screws, joints and pipe connections. Replace part if leak can’t be stopped.

15