BT- 80 specifications

A.O. Smith BT-80 is a notable model in the realm of water heater technology, representing a confluence of efficiency, durability, and advanced engineering. As an industry leader, A.O. Smith has designed this model with the end-user in mind, focusing on delivering a reliable and long-lasting water heating solution suitable for residential and light commercial applications.One of the standout features of the BT-80 is its impressive 80-gallon capacity, which makes it ideal for households with high hot water demands. Whether it's for daily showers, laundry, or dishwashing, this water heater can accommodate the needs of larger families or homes that require a consistent supply of hot water throughout the day.

The BT-80 utilizes a high-efficiency burner that maximizes energy use, ensuring that less fuel is consumed while providing consistent heating performance. This feature not only reduces utility costs for the homeowner but also reinforces A.O. Smith's commitment to environmentally friendly solutions. Additionally, the water heater is equipped with an insulated tank that minimizes heat loss, further improving its efficiency.

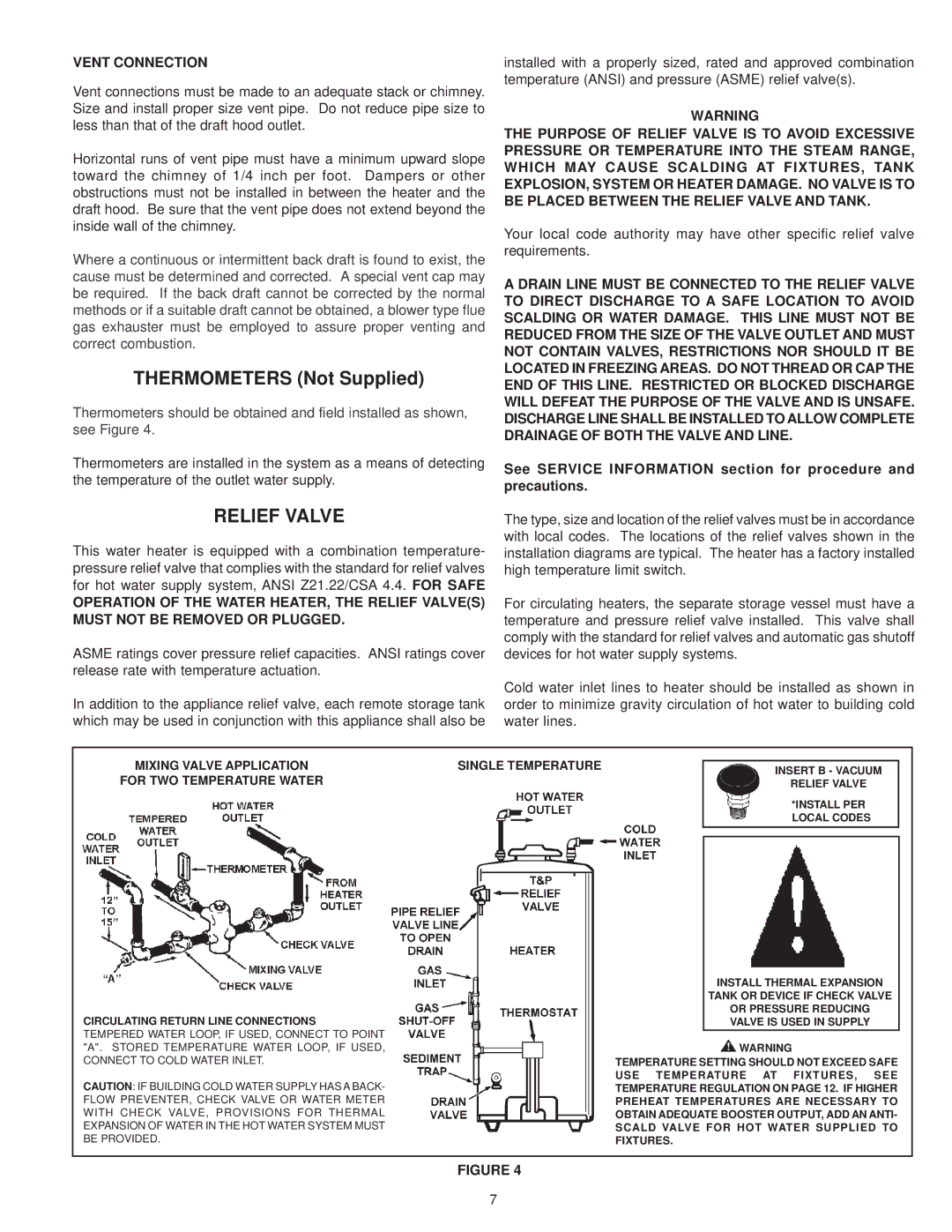

Safety and reliability are key characteristics of the BT-80. It comes with advanced safety features, including a pressure relief valve that prevents excess pressure build-up, ensuring safe operation at all times. The product is also designed for easy maintenance, with accessibility features that allow users or technicians to perform routine checks and repairs conveniently.

This model incorporates cutting-edge technology such as the company's Blue Diamond® glass coating, which provides superior corrosion resistance. This protective feature extends the lifespan of the tank, making it an excellent investment for homeowners.

Moreover, the BT-80 is built to meet stringent industry standards, ensuring it not only performs well but also complies with local codes. Its robust construction means it can withstand various water conditions while maintaining efficiency.

In summary, the A.O. Smith BT-80 is an exemplary water heating solution characterized by its large capacity, energy-efficient operation, advanced safety features, and durable design. It is an ideal choice for customers seeking a reliable and efficient way to meet their hot water needs. With A.O. Smith's reputable engineering and commitment to quality, the BT-80 is a worthy consideration for anyone in the market for a new water heater.