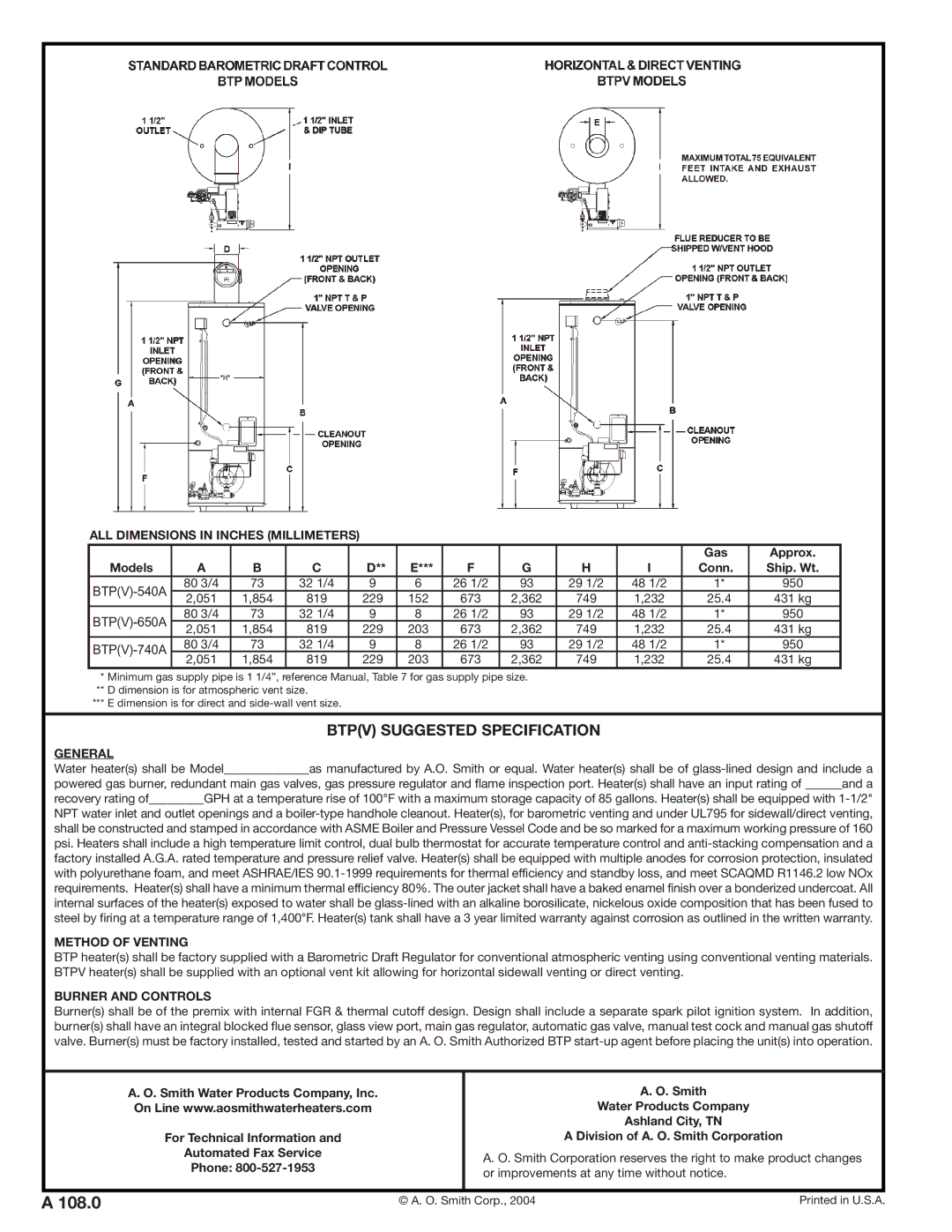

BTP-650A, BTP-540A, BTPV-650A, BTP-740A specifications

A.O. Smith has been a leading name in the water heating industry, known for its innovation and quality. The BTP series, including models BTP-540A, BTP-650A, BTP-740A, and the BTPV-650A, showcases the company's commitment to efficient heating solutions that meet diverse consumer needs.The BTP-540A is designed for residential use, featuring a 40-gallon capacity that is perfect for smaller households. This model utilizes a high-efficiency gas burner that achieves an impressive first-hour rating, ensuring hot water is readily available when needed. The integrated smart technology monitors water usage patterns, optimizing heating cycles and improving energy efficiency.

Moving to the BTP-650A, this model boasts a larger 50-gallon capacity, making it suitable for medium-sized families. A.O. Smith incorporates advanced insulation technology in this tank to minimize heat loss, ensuring that energy is conserved effectively. Additionally, the BTP-650A features a user-friendly digital display that allows homeowners to easily adjust settings and monitor performance.

The BTP-740A is the powerhouse of the series, with a robust 75-gallon capacity, ideal for larger households or commercial applications. This model employs a dual heating system that enhances recovery rates, ensuring a consistent supply of hot water even during peak demand. The BTP-740A also includes multiple safety features, such as temperature relief valves and automatic shut-off settings, providing peace of mind for users.

Lastly, the BTPV-650A deviates slightly by featuring a hybrid design that combines a tank storage system with heat pump technology. This unique configuration allows for extraordinary energy efficiency, significantly reducing operational costs. The BTPV-650A can operate in various ambient temperatures, making it versatile for different climates.

All models in the BTP series come equipped with A.O. Smith's state-of-the-art control systems, promoting user-friendly experiences through real-time monitoring and diagnostics. The durable construction of these water heaters ensures longevity, while features like Wi-Fi connectivity in certain models allow for remote monitoring and management via smartphone apps.

In summary, the A.O. Smith BTP-540A, BTP-650A, BTP-740A, and BTPV-650A are designed with a strong focus on efficiency, capacity, and innovative technology, catering to a wide range of residential and commercial hot water needs.