Belt/Bearing Maintenance GB Unit

1.Belts tend to stretch after a period of time.

They should be checked periodically for wear and tightness. When replacing belts, use the same type as supplied with the unit.

2.Matched belts should always be used on units with

3.For belt replacement, loosen the tensioning device enough to allow removal of the belt by hand.

4.Once installed, adjust belts as shown in “Pre‑Starting Checks.”

5.Shaft bearings can be classified in two groups: relubricating and

6.On GB belt driven fans, the standard cast pillow block bearings are factory lubricated and are provided with external grease fittings. Annual lubrication is recommended, or more frequently if needed (See Table 2). Do not

7.Grease fittings should be wiped clean. The unit should be in operation while lubricating. Extreme care should be used around moving parts.

8.Grease should be pumped in very slowly until a slight bead forms around the seal. A high grade lithium base grease should be used. (See Table 3)

9.To ensure tightness, check pulley setscrews. Proper keys must be in keyways.

10.Fan RPM should not be readjusted. Only use pulleys of identical size and type when replacing pulleys.

11.During the first few months of operation, check bearing setscrews periodically to ensure tightness.

12.If unit is to be left idle for an extended period, remove belts and store in a cool, dry place to avoid premature belt failure.

Recommended Relubrication

Frequency in Months

NOTE: If unusual environment conditions exist (extreme temperature, moisture or contaminants) more frequent lubrication is required.

A good quality lithium base grease, conforming to NLGI Grade 2 consistency, such as those listed here may be used.

Table 2: Suggested Fan Bearing Greasing Intervals

Interval | Type of Service | |

(months) | ||

| ||

|

| |

1 to 3 | Heavy duty in dirty, dusty locations; high ambient | |

temperatures; moisture laden atmosphere; vibration. | ||

| ||

|

| |

3 to 6 | 12 to 24 hours per day, heavy duty, or if moisture is | |

present | ||

| ||

|

| |

6 to 12 | 8 to 16 hours per day in clean, relatively dry | |

atmosphere | ||

| ||

|

| |

12 to 18 | Infrequent operation or light duty in clean | |

atmosphere | ||

| ||

|

| |

|

| |

| Table 3: Grease Manufacturers | |

|

|

Manufacturer | Grease (NLGI #2) | |

|

| |

U.S. Electric Motors | Grease No. 83343 | |

|

| |

Chevron U.S.A. Inc | Chevron SRI Grease #2 | |

Mobil Oil Corporation | Mobilith | |

Mobil 532 | ||

| ||

Texaco, Inc. | Premium BRB #2 | |

Texaco Multifak #2 | ||

| ||

Amoco Oil Co. | Rykon Premium #2 | |

Exxon | Unirex N2 | |

Shell | B Shell Alvania #2 |

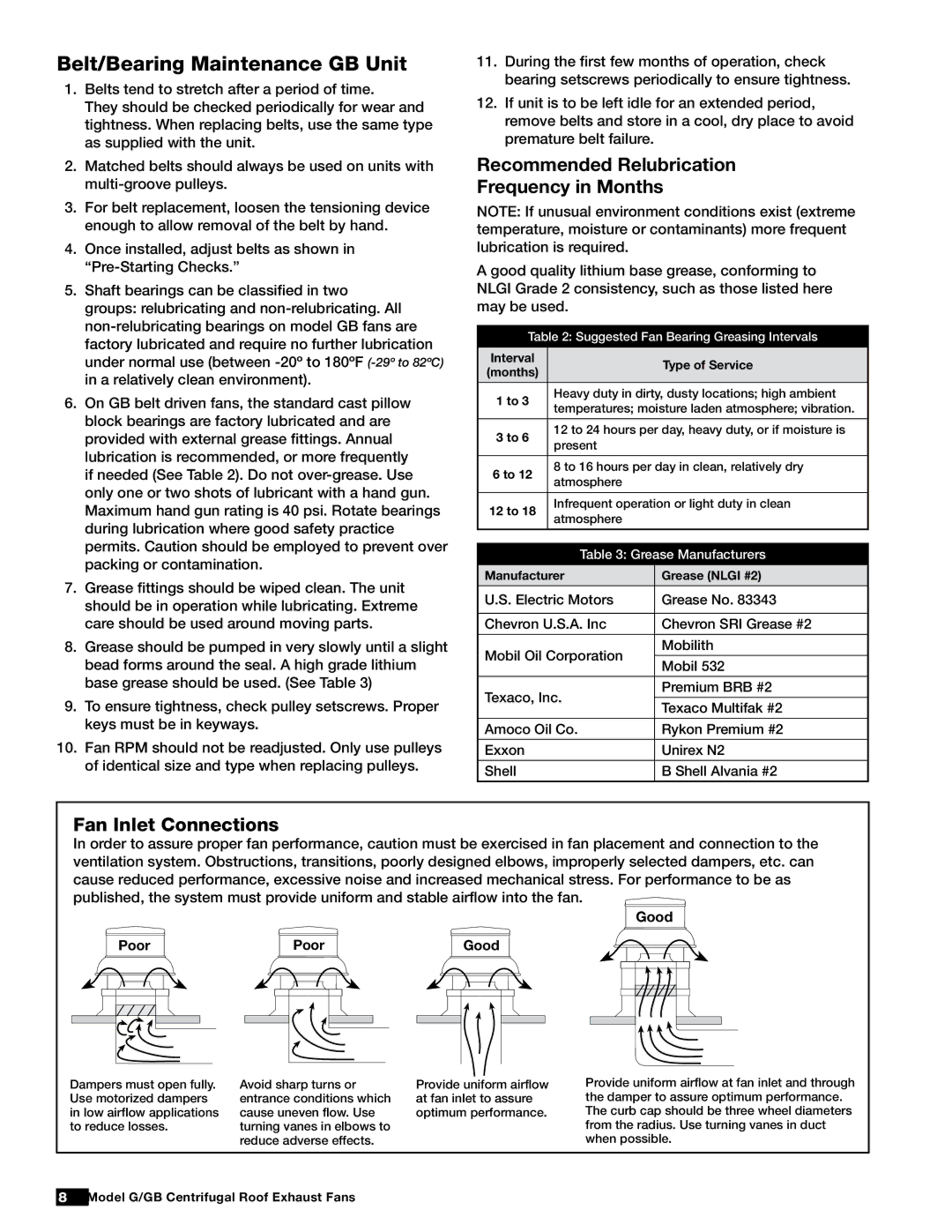

Fan Inlet Connections

In order to assure proper fan performance, caution must be exercised in fan placement and connection to the ventilation system. Obstructions, transitions, poorly designed elbows, improperly selected dampers, etc. can cause reduced performance, excessive noise and increased mechanical stress. For performance to be as published, the system must provide uniform and stable airflow into the fan.

Good

|

|

|

| Poor |

|

|

|

|

| Poor |

|

|

| Good |

|

|

| ||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dampers must open fully. Use motorized dampers in low airflow applications to reduce losses.

Avoid sharp turns or entrance conditions which cause uneven flow. Use turning vanes in elbows to reduce adverse effects.

Provide uniform airflow at fan inlet to assure optimum performance.

Provide uniform airflow at fan inlet and through the damper to assure optimum performance. The curb cap should be three wheel diameters from the radius. Use turning vanes in duct when possible.

8 Model G/GB Centrifugal Roof Exhaust Fans

®