Pre-Starting Checks

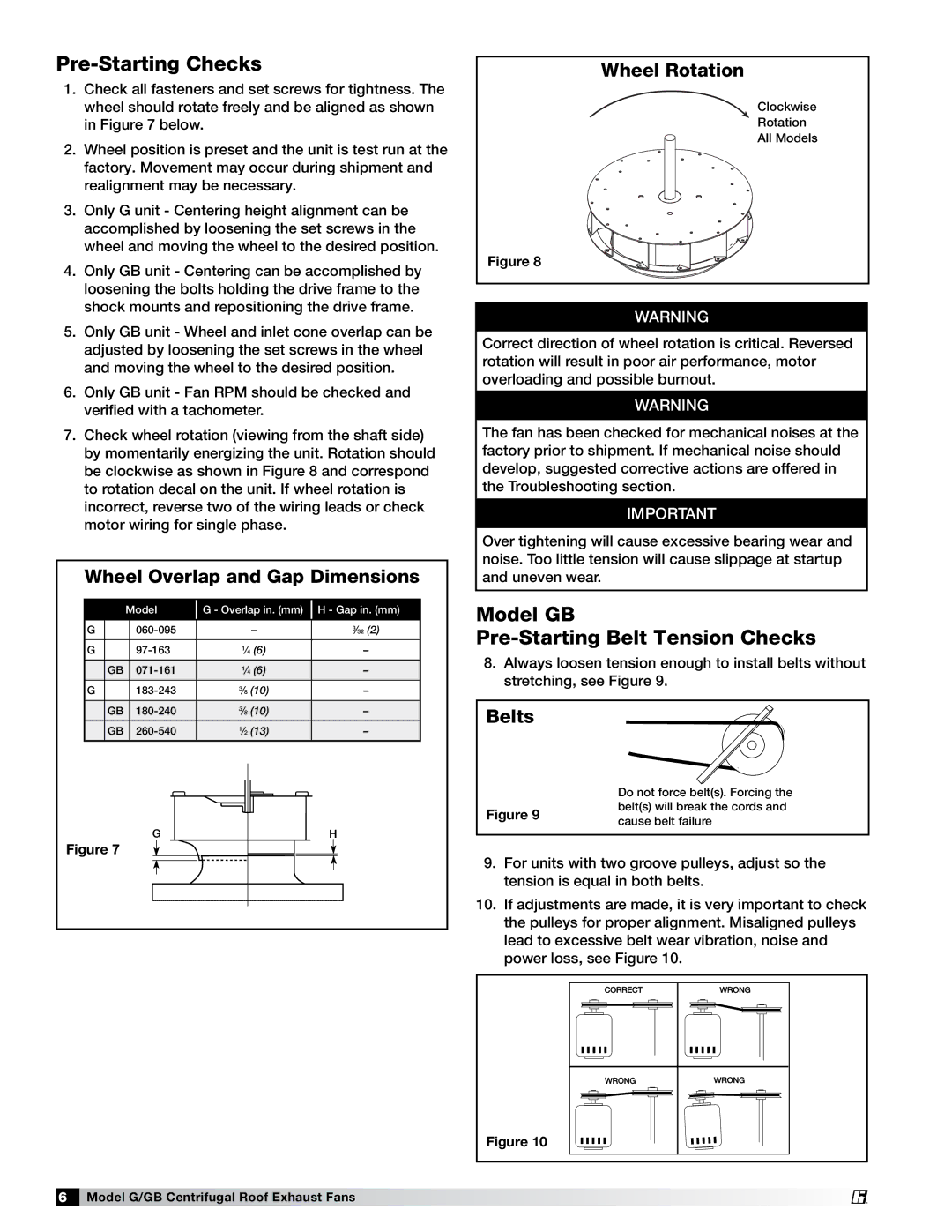

1.Check all fasteners and set screws for tightness. The wheel should rotate freely and be aligned as shown in Figure 7 below.

2.Wheel position is preset and the unit is test run at the factory. Movement may occur during shipment and realignment may be necessary.

3.Only G unit - Centering height alignment can be accomplished by loosening the set screws in the wheel and moving the wheel to the desired position.

4.Only GB unit - Centering can be accomplished by loosening the bolts holding the drive frame to the shock mounts and repositioning the drive frame.

5.Only GB unit - Wheel and inlet cone overlap can be adjusted by loosening the set screws in the wheel and moving the wheel to the desired position.

6.Only GB unit - Fan RPM should be checked and verified with a tachometer.

7.Check wheel rotation (viewing from the shaft side) by momentarily energizing the unit. Rotation should be clockwise as shown in Figure 8 and correspond to rotation decal on the unit. If wheel rotation is incorrect, reverse two of the wiring leads or check motor wiring for single phase.

Wheel Overlap and Gap Dimensions

| Model | G - Overlap in. (mm) | H - Gap in. (mm) | |

G |

| – | 3⁄32 (2) | |

G | 1⁄4 (6) | – | ||

GB | 1⁄4 (6) | – | ||

G | 3⁄8 | (10) | – | |

GB | 3⁄8 | (10) | – | |

GB | 1⁄2 | (13) | – | |

| G |

|

| H |

Figure 7 |

|

|

|

|

Wheel Rotation

Clockwise

Rotation

All Models

Figure 8

WARNING

Correct direction of wheel rotation is critical. Reversed rotation will result in poor air performance, motor overloading and possible burnout.

WARNING

The fan has been checked for mechanical noises at the factory prior to shipment. If mechanical noise should develop, suggested corrective actions are offered in the Troubleshooting section.

IMPORTANT

Over tightening will cause excessive bearing wear and noise. Too little tension will cause slippage at startup and uneven wear.

Model GB

Pre-Starting Belt Tension Checks

8.Always loosen tension enough to install belts without stretching, see Figure 9.

Belts

Do not force belt(s). Forcing the

Figure 9 belt(s) will break the cords and cause belt failure

9.For units with two groove pulleys, adjust so the tension is equal in both belts.

10.If adjustments are made, it is very important to check the pulleys for proper alignment. Misaligned pulleys lead to excessive belt wear vibration, noise and power loss, see Figure 10.

Figure 10

6 Model G/GB Centrifugal Roof Exhaust Fans

®