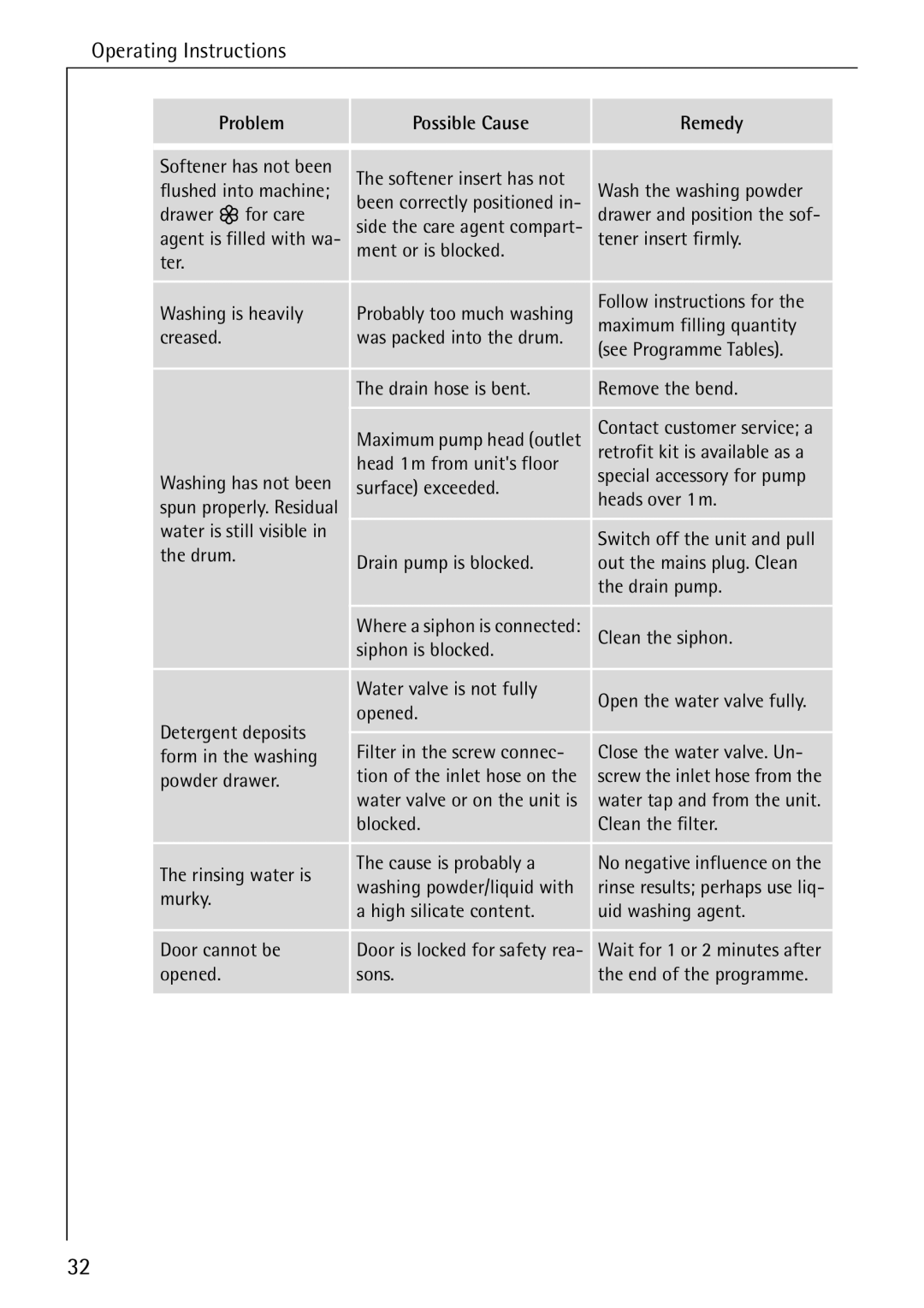

Operating Instructions

Problem | Possible Cause | Remedy | |

Softener has not been | The softener insert has not |

| |

flushed into machine; | Wash the washing powder | ||

been correctly positioned in- | |||

drawer æfor care | drawer and position the sof- | ||

agent is filled with wa- | side the care agent compart- | tener insert firmly. | |

ment or is blocked. | |||

ter. |

|

| |

Washing is heavily | Probably too much washing | Follow instructions for the | |

maximum filling quantity | |||

creased. | was packed into the drum. | ||

(see Programme Tables). | |||

|

| ||

| The drain hose is bent. | Remove the bend. | |

| Maximum pump head (outlet | Contact customer service; a | |

| retrofit kit is available as a | ||

Washing has not been | head 1m from unit's floor | special accessory for pump | |

surface) exceeded. | |||

heads over 1m. | |||

spun properly. Residual |

| ||

|

| ||

water is still visible in |

| Switch off the unit and pull | |

the drum. |

| ||

Drain pump is blocked. | out the mains plug. Clean | ||

| |||

|

| the drain pump. | |

| Where a siphon is connected: | Clean the siphon. | |

| siphon is blocked. |

| |

| Water valve is not fully | Open the water valve fully. | |

| opened. | ||

Detergent deposits |

| ||

Filter in the screw connec- | Close the water valve. Un- | ||

form in the washing | |||

powder drawer. | tion of the inlet hose on the | screw the inlet hose from the | |

| water valve or on the unit is | water tap and from the unit. | |

| blocked. | Clean the filter. | |

The rinsing water is | The cause is probably a | No negative influence on the | |

washing powder/liquid with | rinse results; perhaps use liq- | ||

murky. | |||

a high silicate content. | uid washing agent. | ||

| |||

Door cannot be | Door is locked for safety rea- | Wait for 1 or 2 minutes after | |

opened. | sons. | the end of the programme. | |

|

|

|

32