TACT SwitchTM

Soldering Conditions

Soldering Conditions

Condition for Reflow

Condition for Reflow

Available for Surface Mount Type.

1. | Heating method: Double heating method with infrared heater. |

2. | Temperature measurement: Thermocouple 0.1 to 0.2φ CA(K)or CC(T)at solder joints(copper foil surface). A heat resistive tape |

Detector | should be used to fix thermocouple. |

| |

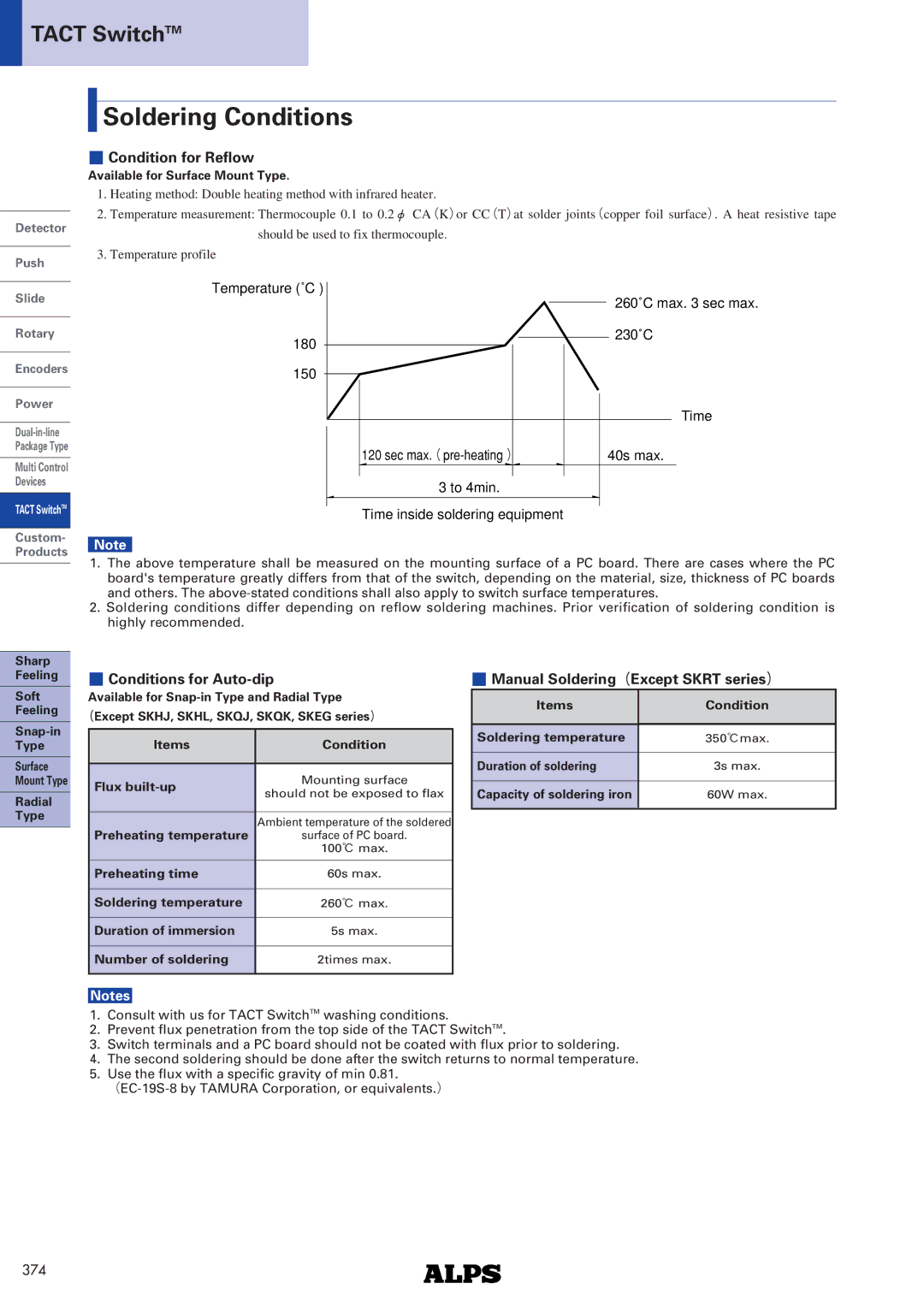

3. | Temperature profile |

Push |

|

Slide

Rotary

Encoders

Power

Multi Control Devices

TACT SwitchTM

Custom- Products

Temperature (˚C )

180

150

Note

260˚C max. 3 sec max.

230˚C

Time

120 sec max(. | 40s max. |

3 to 4min.

Time inside soldering equipment

1.The above temperature shall be measured on the mounting surface of a PC board. There are cases where the PC board's temperature greatly differs from that of the switch, depending on the material, size, thickness of PC boards and others. The

2.Soldering conditions differ depending on reflow soldering machines. Prior verification of soldering condition is highly recommended.

Sharp Feeling

Soft Feeling

Surface Mount Type

Radial

Type

Conditions for

Conditions for Auto-dip

Available for

(Except SKHJ, SKHL, SKQJ, SKQK, SKEG series)

Items | Condition | |

|

| |

Flux | Mounting surface | |

should not be exposed to flax | ||

| ||

|

| |

Preheating temperature | Ambient temperature of the soldered | |

surface of PC board. | ||

| 100℃ max. | |

Preheating time | 60s max. | |

|

| |

Soldering temperature | 260℃ max. | |

|

| |

Duration of immersion | 5s max. | |

|

| |

Number of soldering | 2times max. | |

|

|

Manual Soldering(Except SKRT series)

Manual Soldering(Except SKRT series)

Items | Condition |

|

|

Soldering temperature | 350℃max. |

|

|

Duration of soldering | 3s max. |

|

|

Capacity of soldering iron | 60W max. |

|

|

Notes

1.Consult with us for TACT SwitchTM washing conditions.

2.Prevent flux penetration from the top side of the TACT SwitchTM.

3.Switch terminals and a PC board should not be coated with flux prior to soldering.

4.The second soldering should be done after the switch returns to normal temperature.

5.Use the flux with a specific gravity of min 0.81.

374