CHOOSING THE RIGHT REMOTE MOUNT BLOWER

Below is a chart of the recommended ALDES fans that can be used with the HLS & HLD Series range hood liners. Some models are for mounting remotely in the attic. Other models are used when installation requires a roof mount or wall mount fan.

HLS 30 & HLS 36

Model | Location | Mounting | Airflow @ 0" | Typical Airflow† |

interior | inline | 257 | 190 | |

A6HP | interior | inline | 392 | 275 |

exterior | wall | 381 | 330 | |

exterior | roof | 227 | 205 |

HLD 36

Model | Location | Mounting | Airflow @ 0" | Typical Airflow† |

| interior | inline | 521 | 450 |

interior | inline | 836 | 650 | |

exterior | wall | 435 | 370 | |

exterior | roof/wall | 401 | 350 |

HLD 42 & HLD 48

Model | Location | Mounting | Airflow @ 0" | Typical Airflow† |

interior | inline | 590 | 525 | |

| interior | inline | 1266 | 1020 |

exterior | roof/wall | 753 | 721 | |

exterior | roof/wall | 1008 | 919 |

†Typical airflow is an estimate based on a system with

*Representative of

NOTE: Due to the large volume of air that these remote blowers move, it is important that a source of sufficient makeup air is available to avoid backdrafting in the house.

PART 2 Electrical Connection

WARNINGS:

1.Ensure that the power supply is disconnected before proceeding.

2.Verify that the power supply matches the ratings found on the appliance data label before proceeding.

3.The complete appliance must be properly grounded at all times when electrical power is applied.

4.Do not ground the appliance with the neutral (white) house supply wire. A separate ground wire must be utilized.

5.Failure to complete electrical connections properly may result in damaged or nonfunc- tional systems. Follow instructions carefully to ensure proper installation.

•It is the owner’s responsibility to ensure that a qualified electrician performs the electrical connection of this appliance. The electrical installation, including minimum supply wire size, must comply with the National Electric Code ANSI/NFPA

•A copy of this standard may be obtained from National Fire Protection Association, 1 Batterymarch Park Quincy, Massachusetts

INSTRUCTIONS:

1.A 15 to 20 amp electrical service is recommended for proper electrical supply. Before determining, calculate amp ratings based on the product label found on the liner and the ventilator. (Always observe local building codes).

2.Always use a dedicated circuit.

3.Line load is calculated by adding the amperage of the halogen lights to the rated amper- age of the ventilator (either

4.The ALDES liner is supplied with a 5.0 amp variable speed fan control. Make sure the rated amperage on the ventilator does not exceed 5.0 amps.

5.The ALDES liner has been designed to accommodate several different motor speed controls, (for example ThermadorTM model

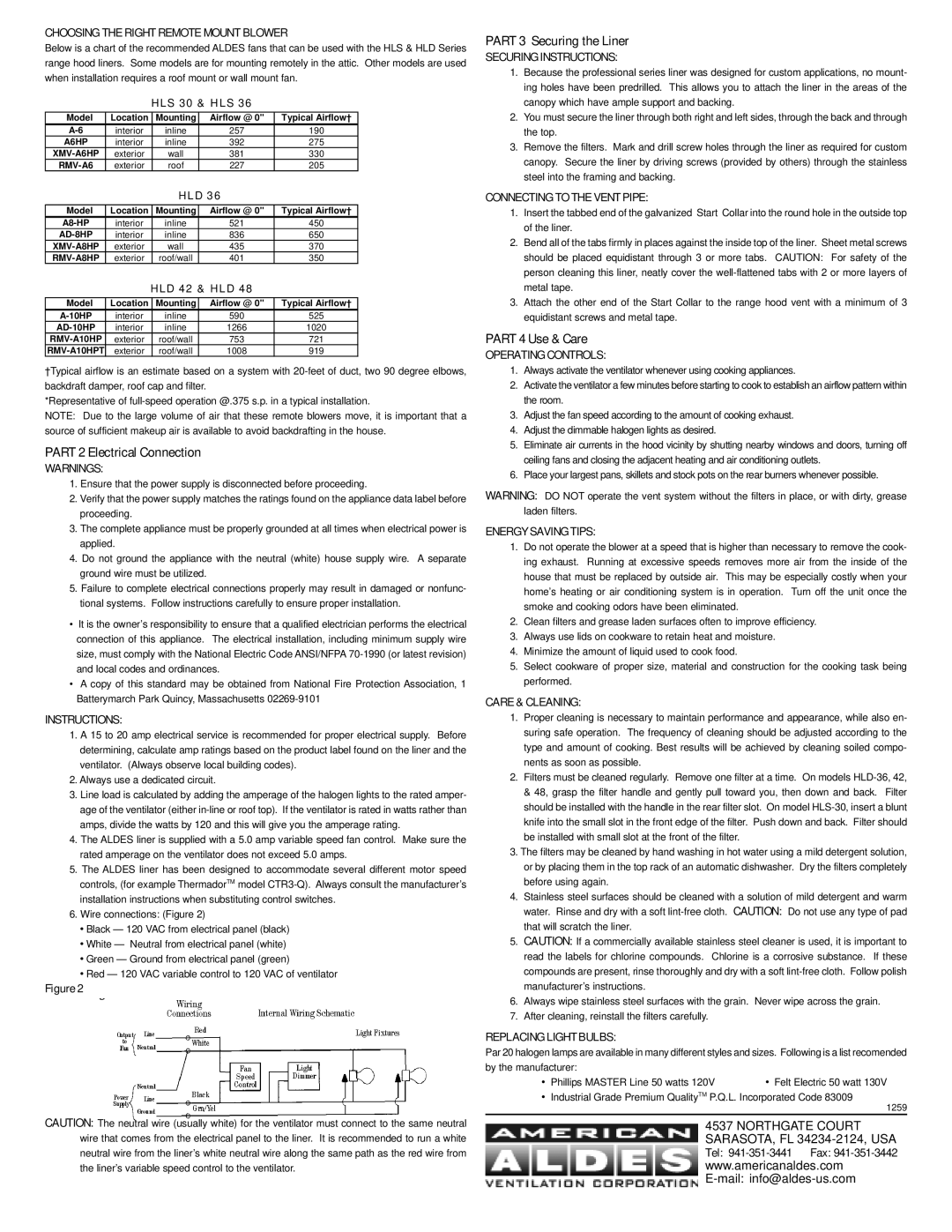

6.Wire connections: (Figure 2)

•Black — 120 VAC from electrical panel (black)

•White — Neutral from electrical panel (white)

•Green — Ground from electrical panel (green)

•Red — 120 VAC variable control to 120 VAC of ventilator

Figure 2

CAUTION: The neutral wire (usually white) for the ventilator must connect to the same neutral wire that comes from the electrical panel to the liner. It is recommended to run a white neutral wire from the liner’s white neutral wire along the same path as the red wire from the liner’s variable speed control to the ventilator.

PART 3 Securing the Liner

SECURING INSTRUCTIONS:

1.Because the professional series liner was designed for custom applications, no mount- ing holes have been predrilled. This allows you to attach the liner in the areas of the canopy which have ample support and backing.

2.You must secure the liner through both right and left sides, through the back and through the top.

3.Remove the filters. Mark and drill screw holes through the liner as required for custom canopy. Secure the liner by driving screws (provided by others) through the stainless steel into the framing and backing.

CONNECTING TO THE VENT PIPE:

1.Insert the tabbed end of the galvanized Start Collar into the round hole in the outside top of the liner.

2.Bend all of the tabs firmly in places against the inside top of the liner. Sheet metal screws should be placed equidistant through 3 or more tabs. CAUTION: For safety of the person cleaning this liner, neatly cover the

3.Attach the other end of the Start Collar to the range hood vent with a minimum of 3 equidistant screws and metal tape.

PART 4 Use & Care

OPERATING CONTROLS:

1.Always activate the ventilator whenever using cooking appliances.

2.Activate the ventilator a few minutes before starting to cook to establish an airflow pattern within the room.

3.Adjust the fan speed according to the amount of cooking exhaust.

4.Adjust the dimmable halogen lights as desired.

5.Eliminate air currents in the hood vicinity by shutting nearby windows and doors, turning off ceiling fans and closing the adjacent heating and air conditioning outlets.

6.Place your largest pans, skillets and stock pots on the rear burners whenever possible.

WARNING: DO NOT operate the vent system without the filters in place, or with dirty, grease laden filters.

ENERGY SAVING TIPS:

1.Do not operate the blower at a speed that is higher than necessary to remove the cook- ing exhaust. Running at excessive speeds removes more air from the inside of the house that must be replaced by outside air. This may be especially costly when your home’s heating or air conditioning system is in operation. Turn off the unit once the smoke and cooking odors have been eliminated.

2.Clean filters and grease laden surfaces often to improve efficiency.

3.Always use lids on cookware to retain heat and moisture.

4.Minimize the amount of liquid used to cook food.

5.Select cookware of proper size, material and construction for the cooking task being performed.

CARE & CLEANING:

1.Proper cleaning is necessary to maintain performance and appearance, while also en- suring safe operation. The frequency of cleaning should be adjusted according to the type and amount of cooking. Best results will be achieved by cleaning soiled compo- nents as soon as possible.

2.Filters must be cleaned regularly. Remove one filter at a time. On models

3.The filters may be cleaned by hand washing in hot water using a mild detergent solution, or by placing them in the top rack of an automatic dishwasher. Dry the filters completely before using again.

4.Stainless steel surfaces should be cleaned with a solution of mild detergent and warm water. Rinse and dry with a soft

5.CAUTION: If a commercially available stainless steel cleaner is used, it is important to read the labels for chlorine compounds. Chlorine is a corrosive substance. If these compounds are present, rinse thoroughly and dry with a soft

6.Always wipe stainless steel surfaces with the grain. Never wipe across the grain.

7.After cleaning, reinstall the filters carefully.

REPLACING LIGHT BULBS:

Par 20 halogen lamps are available in many different styles and sizes. Following is a list recomended by the manufacturer:

• Phillips MASTER Line 50 watts 120V | • Felt Electric 50 watt 130V |

•Industrial Grade Premium QualityTM P.Q.L. Incorporated Code 83009

1259

4537 NORTHGATE COURT SARASOTA, FL

Tel:

www.americanaldes.com