|

|

|

|

|

|

|

|

| MODEL MPVS 100 AND 120 | INSTALLATION |

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| INSTALLATION INSTRUCTIONS | OPERATION |

|

|

|

|

|

|

|

|

| MAINTENANCE | |

|

|

|

|

|

|

|

|

| (Supplement to RDF 09/08) | |

|

|

|

|

|

|

|

|

| 02/09 | |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

General: MPVS Series

The principle advantage of the MPVS central exhaust system is the assurance of controlled indoor air quality ventilation and the elimination of standard noisy bath fans, with the obvious benefits of reduced penetrations to the exterior of the building. Withtheincreasedtightnessofconstruction for energy efficient buildings, there is a growing need of mechanical ventilation for indoor air quality. These fans are designed to serve this purpose as well, by providing effective bathroom ventilation, with the ability to run intermittently or continuously as needed. The quiet, energy efficient permanent split capacitor external rotor motor has permanently sealed bearings that provide many years of maintenance- free performance.

Construction: The MPVS fan is constructed of heavy gauge galvanized steel to prevent corrosion caused by moisture. The cabinet is internally lined with UL rated, acoustic

Fan and Motor: The fan motor is an energy efficient permanent split capacitor type, of external rotor design. Totally sealed to protect against moisture and contaminants, it is approved for use to remove steam and moisture in kitchen and bath areas. The motor incorporates permanently lubricated sealed bearings and automatic reset thermal overload protection. It is designed and certified for continuous duty or intermittent operation.

The fan uses a backward inclined impeller design that minimizes dust from collecting on the blades and affecting airflow performance. Each fan is statically and dynamically balanced in the factory to eliminate vibration and ensure quiet

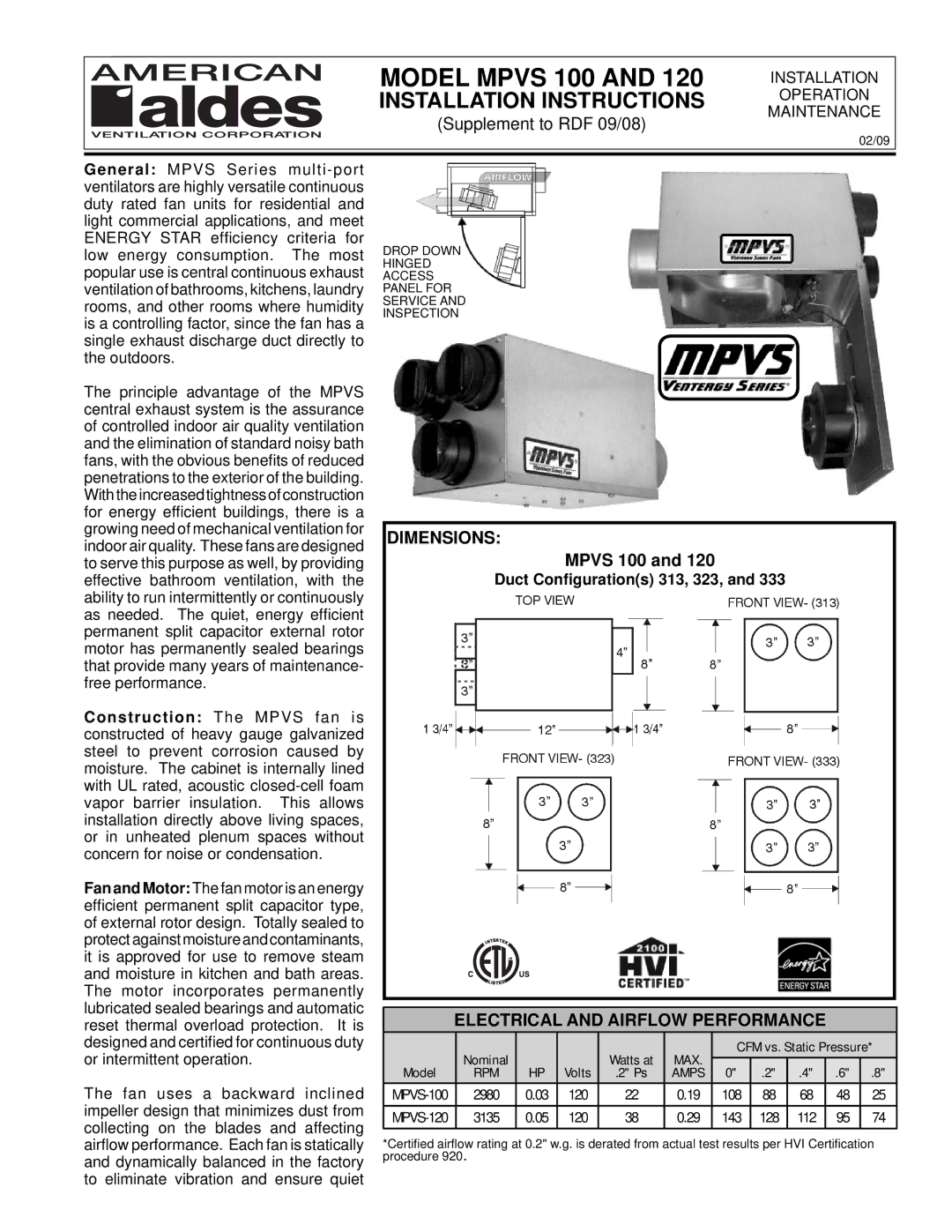

DROP DOWN

HINGED

ACCESS

PANEL FOR

SERVICE AND

INSPECTION

DIMENSIONS:

MPVS 100 and 120

Duct Configuration(s) 313, 323, and 333

ELECTRICAL AND AIRFLOW PERFORMANCE

| Nominal |

|

| Watts at | MAX. | CFM vs. Static Pressure* | |||||

Model | HP | Volts | 0" | .2" | .4" | .6" | .8" | ||||

RPM | .2" Ps | AMPS | |||||||||

| 2980 | 0.03 | 120 | 22 | 0.19 | 108 | 88 | 68 | 48 | 25 | |

| 3135 | 0.05 | 120 | 38 | 0.29 | 143 | 128 | 112 | 95 | 74 | |

*Certified airflow rating at 0.2" w.g. is derated from actual test results per HVI Certification procedure 920.