AD-200 PHASE 7 specifications

American Dryer Corp (ADC) has long been a leader in the laundry equipment industry, and its AD-200 PHASE 7 model is a testament to the company's commitment to innovation and efficiency. Designed for commercial applications, the AD-200 PHASE 7 is a high-performance dryer that sets a new standard for drying technology in laundromats, hotels, and other laundry facilities.One of the standout features of the AD-200 PHASE 7 is its advanced drying system that utilizes a powerful, high-efficiency motor. This motor works in conjunction with a unique airflow design, ensuring that clothes dry quickly and evenly while minimizing energy consumption. The dryer is built to handle large loads, making it an ideal choice for busy commercial environments where efficiency is crucial.

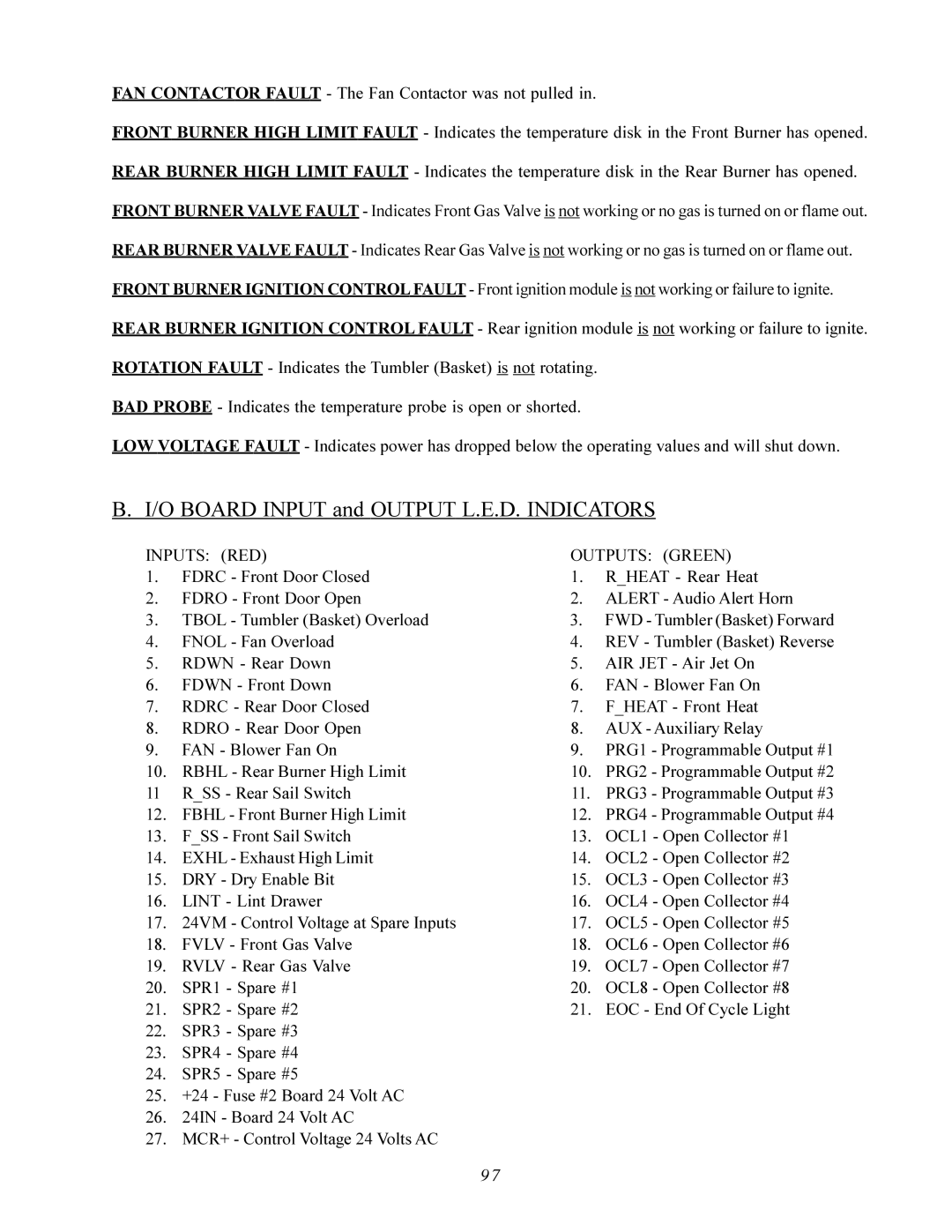

The AD-200 PHASE 7 incorporates state-of-the-art technology to optimize the drying process. It features a microprocessor control system that allows operators to customize drying cycles based on the specific needs of different fabrics. This system not only enhances the user experience by providing precise control but also helps protect garments from over-drying and damage. Additionally, the dryer boasts multiple temperature settings, allowing users to choose the best drying conditions for each load.

Another key characteristic of the AD-200 PHASE 7 is its durable construction. Built with high-quality materials, including reinforced stainless steel, this dryer is designed to withstand the rigors of daily use in a commercial setting. Its robust design not only extends the lifespan of the equipment but also reduces the need for frequent maintenance, which can be a significant cost-saving benefit for businesses.

Energy efficiency is another aspect where the AD-200 PHASE 7 excels. It is equipped with an efficient heat exchange system that recycles hot air during the drying process, reducing energy consumption without compromising performance. This feature contributes to lower utility bills, making it a more sustainable option for businesses looking to improve their environmental footprint.

In conclusion, the American Dryer Corp AD-200 PHASE 7 is a powerful, efficient, and durable commercial dryer that meets the demands of high-volume laundry operations. With its advanced technological features, customizable controls, and energy-saving capabilities, the AD-200 PHASE 7 not only enhances operational efficiency but also provides excellent value for commercial laundry providers. Businesses looking to invest in reliable drying solutions will find the AD-200 PHASE 7 an outstanding choice.