Piping/Connections

MDG31 | MDG51 | MDG77 |

|

|

|

1/2” | 1/2” | 1/2” |

|

|

|

CE dryer connections will be B.S.P.T., all others will be N.P.T.

There should be a minimum

The size of the main gas supply line (header) will vary depending on the distance this line travels from the gas meter or, in the case of L.P. gas, the supply tank, other

Note

!Undersized gas supply piping can create a low or inconsistent pressure, which will result in erratic

operation of the burner ignition system.

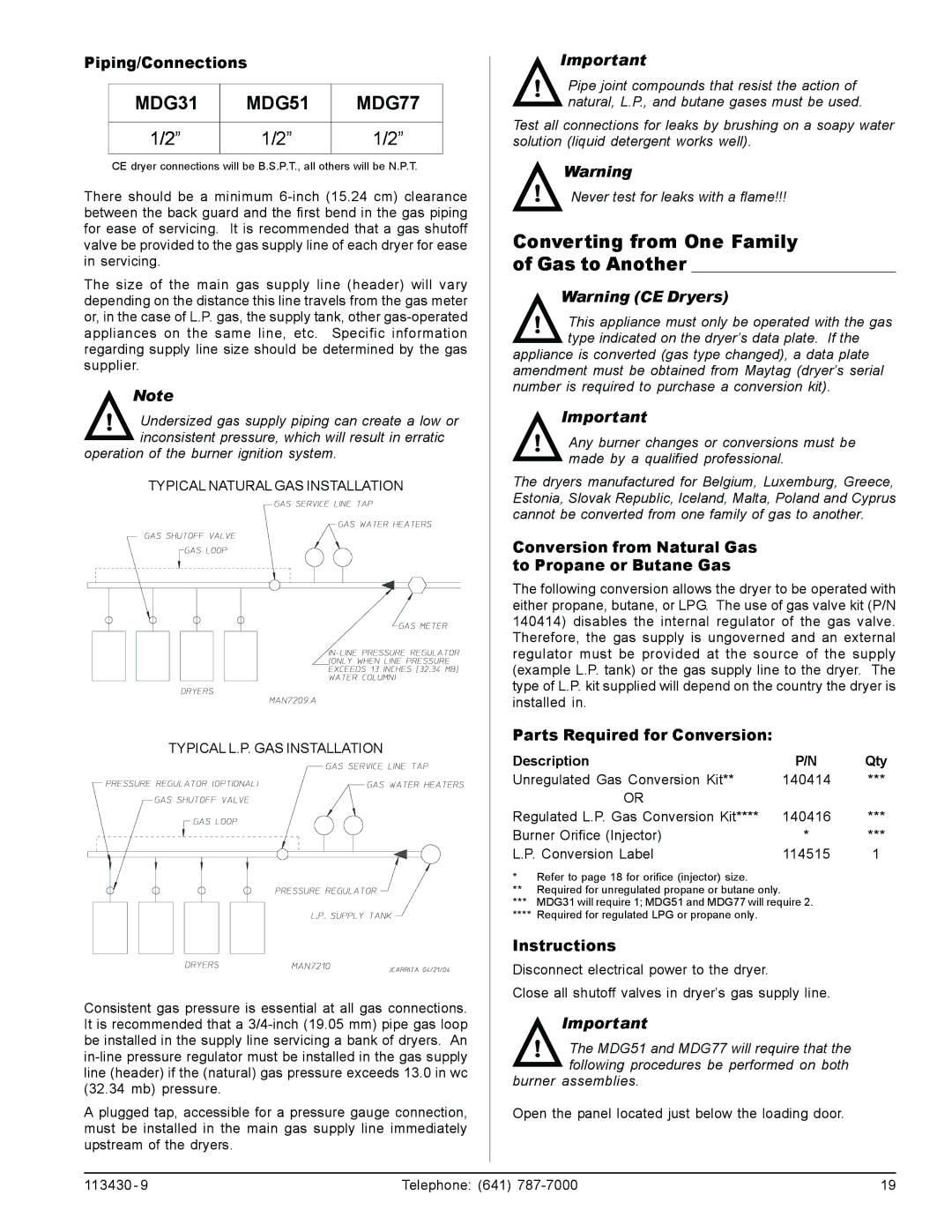

TYPICAL NATURAL GAS INSTALLATION

TYPICAL L.P. GAS INSTALLATION

Consistent gas pressure is essential at all gas connections. It is recommended that a

A plugged tap, accessible for a pressure gauge connection, must be installed in the main gas supply line immediately upstream of the dryers.

Important

!Pipe joint compounds that resist the action of natural, L.P., and butane gases must be used.

Test all connections for leaks by brushing on a soapy water solution (liquid detergent works well).

Warning

!Never test for leaks with a flame!!!

Converting from One Family

of Gas to Another ______________________

Warning (CE Dryers)

!This appliance must only be operated with the gas type indicated on the dryer’s data plate. If the

appliance is converted (gas type changed), a data plate amendment must be obtained from Maytag (dryer’s serial number is required to purchase a conversion kit).

Important

!Any burner changes or conversions must be made by a qualified professional.

The dryers manufactured for Belgium, Luxemburg, Greece, Estonia, Slovak Republic, Iceland, Malta, Poland and Cyprus cannot be converted from one family of gas to another.

Conversion from Natural Gas to Propane or Butane Gas

The following conversion allows the dryer to be operated with either propane, butane, or LPG. The use of gas valve kit (P/N 140414) disables the internal regulator of the gas valve. Therefore, the gas supply is ungoverned and an external regulator must be provided at the source of the supply (example L.P. tank) or the gas supply line to the dryer. The type of L.P. kit supplied will depend on the country the dryer is installed in.

Parts Required for Conversion:

Description | P/N | Qty |

Unregulated Gas Conversion Kit** | 140414 | *** |

OR |

|

|

Regulated L.P. Gas Conversion Kit**** | 140416 | *** |

Burner Orifice (Injector) | * | *** |

L.P. Conversion Label | 114515 | 1 |

*Refer to page 18 for orifice (injector) size.

**Required for unregulated propane or butane only.

***MDG31 will require 1; MDG51 and MDG77 will require 2.

****Required for regulated LPG or propane only.

Instructions

Disconnect electrical power to the dryer.

Close all shutoff valves in dryer’s gas supply line.

Important

!The MDG51 and MDG77 will require that the following procedures be performed on both

burner assemblies.

Open the panel located just below the loading door.

113430 - 9 | Telephone: (641) | 19 |