Locate the gas train and disconnect the union, 3 electrical plugs, and the gas train mounting screws from the burner. Carefully slide the gas train out of the gas train enclosure. (The carbon ignitor located at the far end of the gas train is very fragile.)

Remove 2 burner tube mounting screws and remove burner tube in order to gain access to the orifice.

Using a 3/8” wrench or socket, remove the existing orifice and replace it with an orifice from the kit.

Important

!Use extreme care when removing and replacing orifice (injector). This orifice (injector) is made of

brass, which is easily damaged.

Reinstall the burner tube onto the burner base.

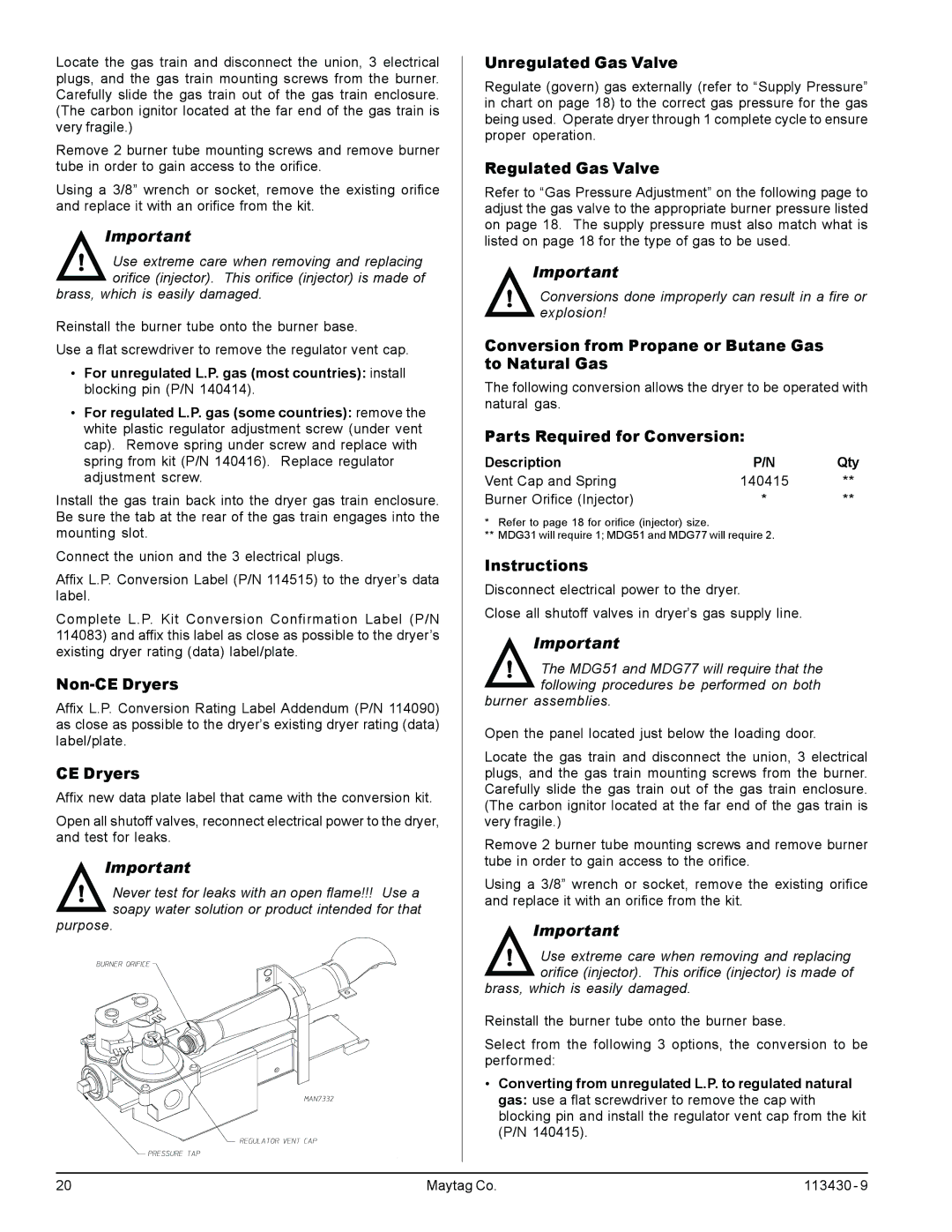

Use a flat screwdriver to remove the regulator vent cap.

•For unregulated L.P. gas (most countries): install blocking pin (P/N 140414).

•For regulated L.P. gas (some countries): remove the white plastic regulator adjustment screw (under vent cap). Remove spring under screw and replace with spring from kit (P/N 140416). Replace regulator adjustment screw.

Install the gas train back into the dryer gas train enclosure. Be sure the tab at the rear of the gas train engages into the mounting slot.

Connect the union and the 3 electrical plugs.

Affix L.P. Conversion Label (P/N 114515) to the dryer’s data label.

Complete L.P. Kit Conversion Confirmation Label (P/N 114083) and affix this label as close as possible to the dryer’s existing dryer rating (data) label/plate.

Non-CE Dryers

Affix L.P. Conversion Rating Label Addendum (P/N 114090) as close as possible to the dryer’s existing dryer rating (data) label/plate.

CE Dryers

Affix new data plate label that came with the conversion kit.

Open all shutoff valves, reconnect electrical power to the dryer, and test for leaks.

Important

!Never test for leaks with an open flame!!! Use a

soapy water solution or product intended for that purpose.

Unregulated Gas Valve

Regulate (govern) gas externally (refer to “Supply Pressure” in chart on page 18) to the correct gas pressure for the gas being used. Operate dryer through 1 complete cycle to ensure proper operation.

Regulated Gas Valve

Refer to “Gas Pressure Adjustment” on the following page to adjust the gas valve to the appropriate burner pressure listed on page 18. The supply pressure must also match what is listed on page 18 for the type of gas to be used.

Important

!Conversions done improperly can result in a fire or explosion!

Conversion from Propane or Butane Gas to Natural Gas

The following conversion allows the dryer to be operated with natural gas.

Parts Required for Conversion:

Description | P/N | Qty |

Vent Cap and Spring | 140415 | ** |

Burner Orifice (Injector) | * | ** |

*Refer to page 18 for orifice (injector) size.

**MDG31 will require 1; MDG51 and MDG77 will require 2.

Instructions

Disconnect electrical power to the dryer.

Close all shutoff valves in dryer’s gas supply line.

Important

!The MDG51 and MDG77 will require that the following procedures be performed on both

burner assemblies.

Open the panel located just below the loading door.

Locate the gas train and disconnect the union, 3 electrical plugs, and the gas train mounting screws from the burner. Carefully slide the gas train out of the gas train enclosure. (The carbon ignitor located at the far end of the gas train is very fragile.)

Remove 2 burner tube mounting screws and remove burner tube in order to gain access to the orifice.

Using a 3/8” wrench or socket, remove the existing orifice and replace it with an orifice from the kit.

Important

!Use extreme care when removing and replacing orifice (injector). This orifice (injector) is made of

brass, which is easily damaged.

Reinstall the burner tube onto the burner base.

Select from the following 3 options, the conversion to be performed:

•Converting from unregulated L.P. to regulated natural gas: use a flat screwdriver to remove the cap with blocking pin and install the regulator vent cap from the kit (P/N 140415).

20 | Maytag Co. | 113430 - 9 |