OWNER'S MANUAL

NG401, NG401A

(12 Volt DC)

NG405 - NG405A

(12 Volt AC)

Natural Gas Detector

(12 Volt Hard-Wired with Optional

Relay Output)

IMPORTANT:

NOT SUITABLE AS A CARBON MONOXIDE DETECTOR OR A SMOKE OR FIRE DETECTOR. THIS DEVICE IS NOT SUIT- ABLE FOR INSTALLATION IN A HAZ- ARDOUS LOCATION, AS DEFINED IN THE NATIONAL OR CANADIAN ELECTRICAL CODE.

Introducing the NG401, NG401A,

NG405, NG405A Natural Gas

Detector

The NG401, NG401A, NG405, NG405A Natural Gas Detector is an effective product for detecting any buildup of natural gas in your home. Dicon Global Inc., the maker of these natural gas detectors, has been developing and making products for detecting gases since 1985.

Your new detector: Is easy to install

Monitors for natural gas continuously and sounds a loud (85db) alarm when it detects a build-up of natural gas.

Has a Test button so that you can test it at any time.

Tests itself continuously.

Is listed by the Underwriters Laboratories to UL1484 standard.

Has a 5-year guarantee for the natural gas sensing element.

A. Why should you be concerned about natural gas?

The harmful element in natural gas is methane, a colorless, odorless, and flammable gas. As natural gas builds up, it mixes with oxygen to produce a mixture that can be explosive if ignited by a spark or flame.

Most likely sources of leaks are gas appli- ances, heaters, stoves, refrigerators, and fur- naces. Gas leaks from outside or below groundlevel can also seep into your home.

B. Where should you install the detector?

Natural gas is lighter than air and therefore collects in the highest areas of rooms and homes. To detect a dangerous concentration of natural gas, you should place your detector near a natural gas appliance or in a room above the appliance. For example a natural gas leak in the kitchen can create a build up in the floors above.

You should place your detector as close to the ceiling as possible.

C. How should you install the detector?

You must install the NG401, NG401A, NG405, NG405A Natural Gas Detector on a wall within

36 inches of the ceiling.

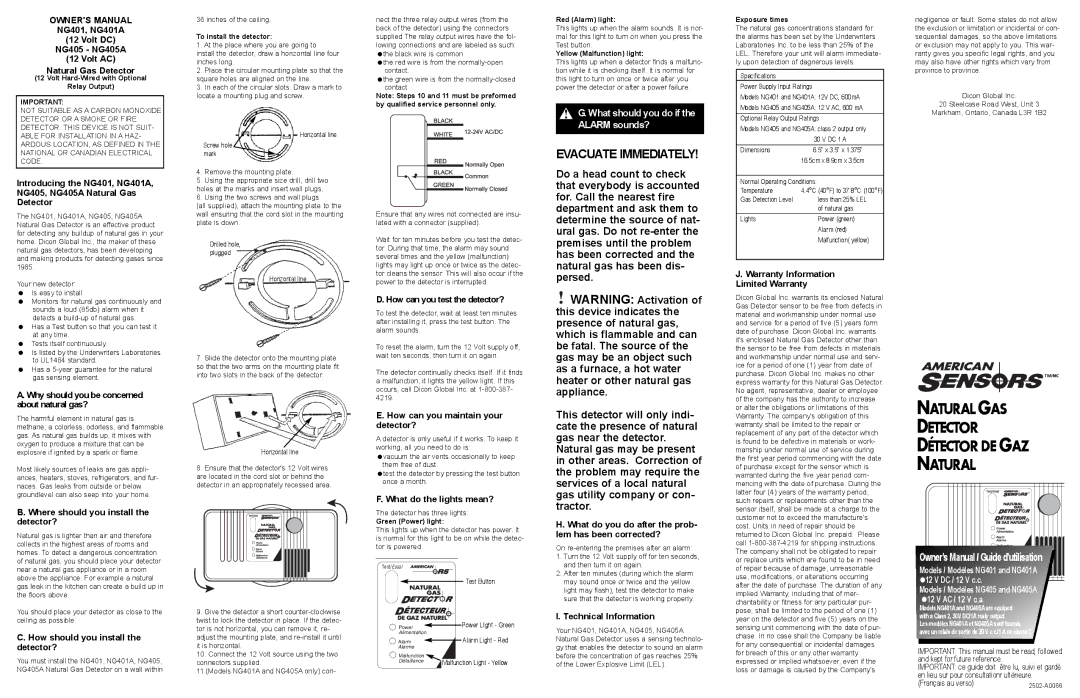

To install the detector:

1. At the place where you are going to

install the detector, draw a horizontal line four inches long.

2.Place the circular mounting plate so that the square holes are aligned on the line.

3.In each of the circular slots. Draw a mark to locate a mounting plug and screw.

Horizontal line

Screw hole mark

4.Remove the mounting plate.

5.Using the appropriate size drill, drill two holes at the marks and insert wall plugs.

6.Using the two screws and wall plugs

(all supplied), attach the mounting plate to the wall ensuring that the cord slot in the mounting plate is down.

Drilled hole, plugged

Horizontal line

7.Slide the detector onto the mounting plate so that the two arms on the mounting plate fit into two slots in the back of the detector.

Horizontal line

8.Ensure that the detector's 12 Volt wires are located in the cord slot or behind the detector in an appropriately recessed area.

9.Give the detector a short counter-clockwise twist to lock the detector in place. If the detec- tor is not horizontal, you can remove it, re- adjust the mounting plate, and re-install it until it is horizontal.

10.Connect the 12 Volt source using the two connectors supplied.

11.(Models NG401A and NG405A only) con-

nect the three relay output wires (from the back of the detector) using the connectors supplied.The relay output wires have the fol- lowing connections and are labeled as such:

the black wire is common

the red wire is from the normally-open contact.

the green wire is from the normally-closed contact

Note: Steps 10 and 11 must be preformed by qualified service personnel only.

Ensure that any wires not connected are insu- lated with a connector (supplied).

Wait for ten minutes before you test the detec- tor. During that time, the alarm may sound several times and the yellow (malfunction) lights may light up once or twice as the detec- tor cleans the sensor. This will also occur if the power to the detector is interrupted.

D. How can you test the detector?

To test the detector, wait at least ten minutes after installing it, press the test button. The alarm sounds.

To reset the alarm, turn the 12 Volt supply off, wait ten seconds, then turn it on again.

The detector continually checks itself. If it finds a malfunction, it lights the yellow light. If this occurs, call Dicon Global Inc. at 1-800-387- 4219.

E. How can you maintain your detector?

A detector is only useful if it works. To keep it working, all you need to do is:

vacuum the air vents occasionally to keep them free of dust.

test the detector by pressing the test button once a month.

F. What do the lights mean?

The detector has three lights:

Green (Power) light:

This lights up when the detector has power. It is normal for this light to be on while the detec- tor is powered.

Test/Essai

TM MC

Test Button

Power | | | Power LIght - Green |

| |

Alimentation | | | Alarm Light - Red |

Alarm | | |

| |

Alarme | | | |

Malfunction | | Malfunction Light - Yellow |

Défaillance | | | |

| | | |

Red (Alarm) light:

This lights up when the alarm sounds. It is nor- mal for this light to turn on when you press the Test button.

Yellow (Malfunction) light:

This lights up when a detector finds a malfunc- tion while it is checking itself. It is normal for this light to turn on once or twice after you power the detector or after a power failure.

G. What should you do if the ALARM sounds?

G. What should you do if the ALARM sounds?

EVACUATE IMMEDIATELY!

Do a head count to check that everybody is accounted for. Call the nearest fire department and ask them to determine the source of nat- ural gas. Do not re-enter the premises until the problem has been corrected and the natural gas has been dis- persed.

WARNING: Activation of this device indicates the presence of natural gas, which is flammable and can be fatal. The source of the gas may be an object such as a furnace, a hot water heater or other natural gas appliance.

WARNING: Activation of this device indicates the presence of natural gas, which is flammable and can be fatal. The source of the gas may be an object such as a furnace, a hot water heater or other natural gas appliance.

This detector will only indi- cate the presence of natural gas near the detector.

Natural gas may be present in other areas. Correction of the problem may require the services of a local natural gas utility company or con- tractor.

H. What do you do after the prob- lem has been corrected?

On re-entering the premises after an alarm:

1.Turn the 12 Volt supply off for ten seconds, and then turn it on again.

2.After ten minutes (during which the alarm may sound once or twice and the yellow light may flash), test the detector to make sure that the detector is working properly.

I. Technical Information

Your NG401, NG401A, NG405, NG405A Natural Gas Detector uses a sensing technolo- gy that enables the detector to sound an alarm before the concentration of gas reaches 25% of the Lower Explosive Limit (LEL).

Exposure times

The natural gas concentrations standard for the alarms has been set by the Underwriters Laboratories Inc. to be less than 25% of the LEL. Therefore your unit will alarm immediate- ly upon detection of dagnerous levels.

Specifications

Power Supply Input Ratings

Models NG401 and NG401A: 12V DC, 600mA

Models NG405 and NG405A: 12 V AC, 600 mA

Optional Relay Output Ratings

Models NG405 and NG405A: class 2 output only

| 30 V DC 1 A |

Dimensions | 6.5” x 3.5” x 1.375” |

| 16.5cm x 8.9cm x 3.5cm |

|

Normal Operating Conditions: |

Temperature | 4.4°C (40°F) to 37.8°C (100°F) |

Gas Detection Level | less than 25% LEL |

| of natural gas |

Lights | Power (green) |

| Alarm (red) |

| Malfunction( yellow) |

J. Warranty Information

Limited Warranty

Dicon Global Inc. warrants its enclosed Natural Gas Detector sensor to be free from defects in material and workmanship under normal use and service for a period of five (5) years form date of purchase. Dicon Global Inc. warrants it's enclosed Natural Gas Detector other than the sensor to be free from defects in materials and workmanship under normal use and serv- ice for a period of one (1) year from date of purchase. Dicon Global Inc. makes no other express warranty for this Natural Gas Detector. No agent, representative, dealer or employee of the company has the authority to increase or alter the obligations or limitations of this Warranty. The company's obligation of this warranty shall be limited to the repair or replacement of any part of the detector which is found to be defective in materials or work- manship under normal use of service during the first year period commencing with the date of purchase except for the sensor which is warranted during the five year period com- mencing with the date of purchase. During the latter four (4) years of the warranty period, such repairs or replacements other than the sensor itself, shall be made at a charge to the customer not to exceed the manufacture's cost. Units in need of repair should be returned to Dicon Global Inc. prepaid. Please call 1-800-387-4219 for shipping instructions. The company shall not be obligated to repair or replace units which are found to be in need of repair because of damage, unreasonable use, modifications, or alterations occurring after the date of purchase. The duration of any implied Warranty, including that of mer- chantability or fitness for any particular pur- pose, shall be limited to the period of one (1) year on the detector and five (5) years on the sensing unit commencing with the date of pur- chase. In no case shall the Company be liable for any consequential or incidental damages for breach of this or any other warranty expressed or implied whatsoever, even if the loss or damage is caused by the Company's

negligence or fault. Some states do not allow the exclusion or limitation or incidental or con- sequential damages, so the above limitations or exclusion may not apply to you. This war- ranty gives you specific legal rights, and you may also have other rights which vary from province to province.

Dicon Global Inc.

20 Steelcase Road West, Unit 3

Markham, Ontario, Canada L3R 1B2

NATURAL GAS

DETECTOR

DÉTECTOR DE GAZ

NATURAL

Owner’s Manual / Guide d’utilisation

Models / Modèles NG401 and NG401A z12 V DC / 12 V c.c.

Models / Modèles NG405 and NG405A z12 V AC / 12 V c.a.

Models NG401A and NG405A are equiped with a Class 2, 30V DC/1A realy output

Les modèles NG401A et NG405A sont fournis avec un relais de sortie de 30 V c.c./1 A de classe 2

IMPORTANT: This manual must be read, followed and kept for future reference.

IMPORTANT: ce guide doit être lu, suivi et gardé en lieu sur pour consultationr ultérieure. (Français au verso)