1480SS.500, T480.500 specifications

The American Standard T480.500,1480SS.500 is an advanced faucet model that epitomizes modern design and innovative technology. With a sleek and contemporary appearance, this faucet not only enhances the aesthetic appeal of any bathroom but also offers high functionality and durability.One of the standout features of the T480.500 is its solid brass construction, which ensures long-lasting performance and resistance to corrosion. This material not only contributes to the faucet's durability but also provides a premium feel. The chrome finish adds a touch of elegance, making it suitable for both classic and contemporary bathroom styles.

The T480.500 faucet incorporates advanced water-saving technology, allowing homeowners to reduce water consumption without sacrificing performance. It features a low-flow rate, which helps in conserving water while still delivering a powerful stream. This eco-friendly aspect aligns with the growing demand for sustainable products in modern households.

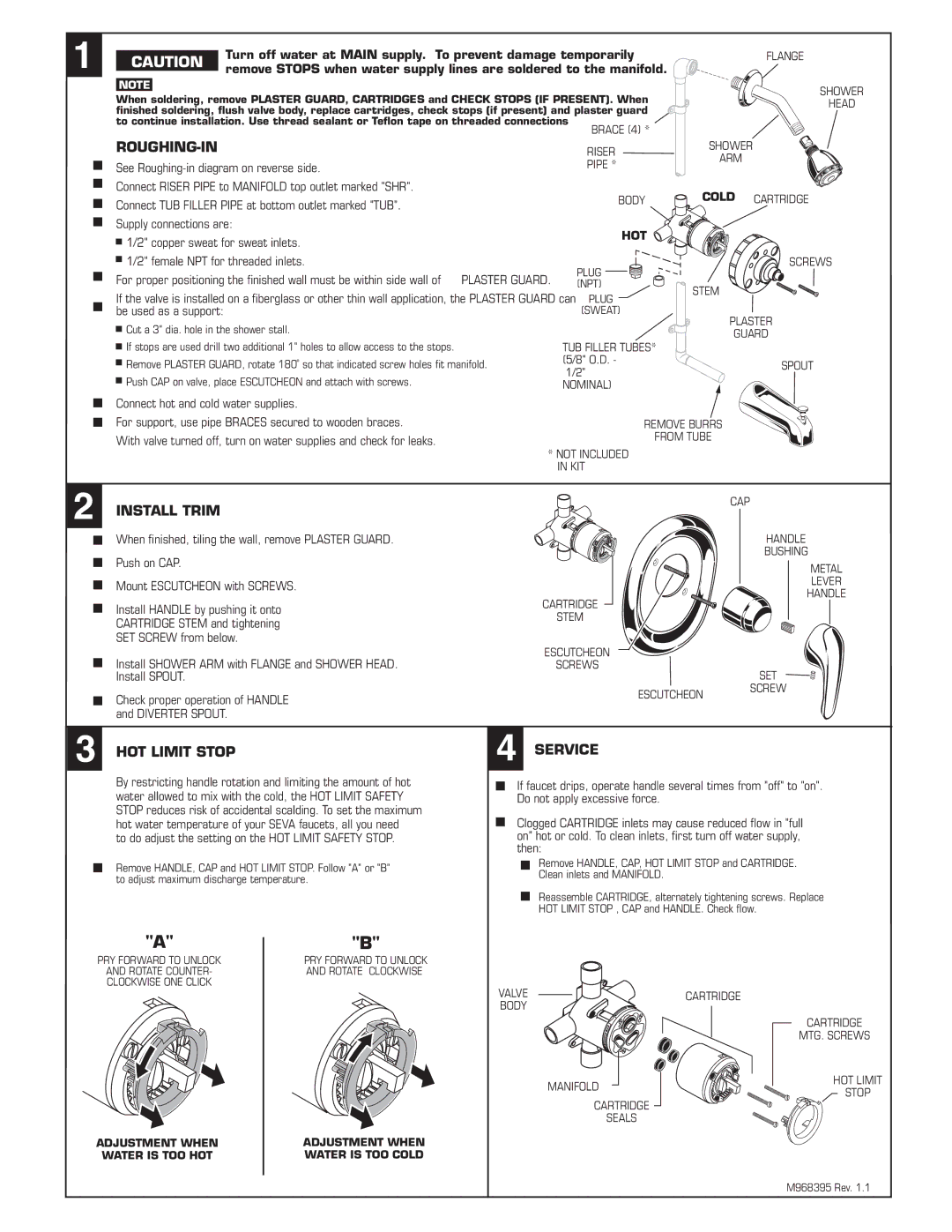

Another important characteristic of this faucet is its easy installation process. Equipped with the Quick Spin utility, the T480.500 can be installed with minimal tools, providing convenience for DIY enthusiasts and professionals alike. The user-friendly design minimizes the potential for leaks, ensuring a reliable, worry-free experience.

In terms of usability, the faucet features a single-handle lever that allows precise water temperature control with just one hand. The smooth operation of the handle enhances the user experience and is particularly beneficial for individuals with limited mobility. This thoughtful design element ensures that users can achieve their desired water temperature effortlessly.

The American Standard T480.500 is also designed with maintenance in mind. Its robust construction and materials reduce the need for frequent repairs and replacements. In addition, the faucet's easy-to-clean surface helps prevent the buildup of water spots and mineral deposits, maintaining its appearance over time.

In summary, the American Standard T480.500,1480SS.500 is a perfect blend of style, efficiency, and ease of use. With its durable brass construction, water-saving technology, and user-friendly design, it stands out as a top choice for homeowners looking to elevate their bathroom fixtures. Whether updating a personal space or considering options for a new build, this faucet represents a modern solution that meets the needs of today's consumers.