Super Cross Grain Sheeter specifications

The AMF Super Cross Grain Sheeter is a revolutionary machine in the baking industry, designed to streamline the dough sheeting process and enhance overall production efficiency. This innovative equipment is a testament to AMF’s commitment to quality and performance, offering bakers exceptional features that cater to both artisan and large-scale operations.One of the standout characteristics of the Super Cross Grain Sheeter is its advanced sheeting technology. It utilizes a unique cross-grain sheeting method, allowing for more uniform dough thickness and texture. This technology ensures that the dough maintains its integrity during the sheeting process, minimizing the risk of tearing and enabling bakers to produce high-quality baked goods with consistent results.

The machine is equipped with a user-friendly control interface that simplifies operation. Bakers can easily adjust settings such as dough thickness and sheeting speed, providing complete control over the sheeting process. This flexibility allows for the production of a variety of baked items, from delicate pastries to robust bread sheets, catering to a wide range of customer needs.

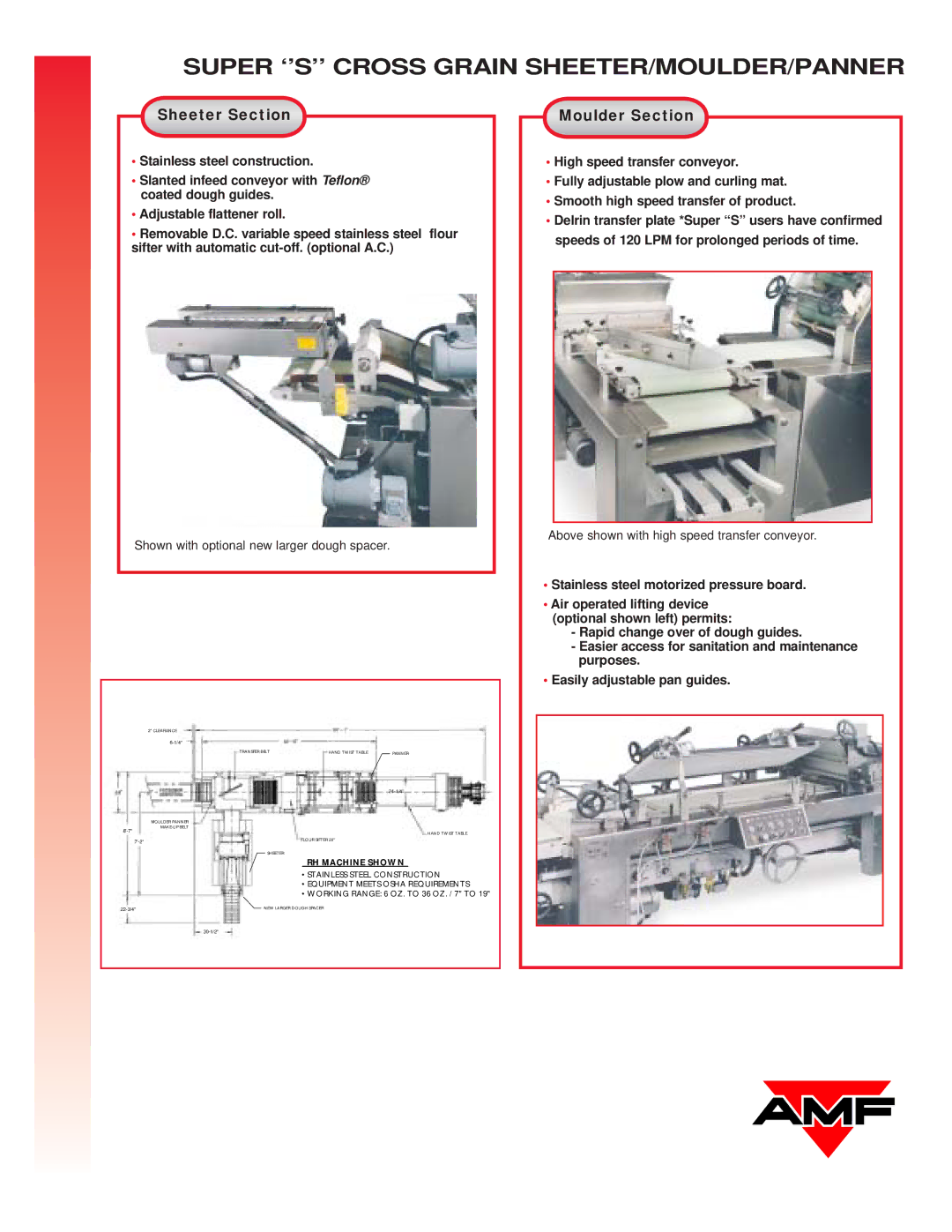

Another key feature of the AMF Super Cross Grain Sheeter is its robust construction and reliability. Built with high-quality materials, it can withstand the demanding environment of a busy bakery. Its design includes easy-to-clean surfaces, ensuring that sanitation standards are met without compromising on efficiency.

In terms of technology, the sheeter is often equipped with a variable frequency drive, allowing precise speed adjustments. This is crucial for working with different types of dough, as it can greatly affect the final product. The machine also incorporates energy-efficient motors, contributing to lower operating costs and a reduced environmental footprint.

Safety is a top priority with the Super Cross Grain Sheeter. It is designed with built-in safety features that protect operators during use. The open design allows for easy access, while guards and emergency stop functions ensure a safe working environment.

In summary, the AMF Super Cross Grain Sheeter stands out with its advanced sheeting technology, user-friendly controls, robust construction, and energy-efficient design. It is a vital asset for any bakery looking to enhance production efficiency while maintaining the quality of their baked goods. With this machine, bakers can achieve consistent results that satisfy customer expectations, making it an invaluable addition to modern baking operations.