MAINTENANCE

WARNING:

When servicing, use only identical Harbor Freight Tools replacement parts. Use of any other parts may create a hazard or cause product damage.

WARNING:

Always wear safety goggles or safety glasses with side shields during power tool operation or when blowing dust. If operation is dusty, also wear a dust mask.

WARNING:

Always release all pressure, disconnect from power supply, and allow unit to cool to the touch before cleaning or making repairs on the air compressor.

GENERAL MAINTENANCE

Humidity in the air causes condensate to form in the air tank. This condensate should be drained daily and/or every hour, using the instructions found in Draining the

Tank.

The safety valve automatically releases air if the air receiver pressure exceeds the preset maximum. Check the safety valve before each use following the instructions

found in Checking the Safety Valve.

Inspect the tank yearly for rust, pin holes, or other imperfections that could cause it to become unsafe.

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of commercial solvents and may be damaged by their use. Use clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline, petroleum- based products, penetrating oils, etc., come in contact with plastic parts. Chemical can damage, weaken or destroy plastic which may result in serious personal injury. Electric tools used on fiberglass material, wall- board, spackling compounds, or plaster are subject

to accelerated wear and possible premature failure because the fiberglass chips and grindings are highly abrasive to bearings, brushes, commutators, etc. Consequently, we do not recommend using this tool for extended work on these type of materials. However, if you do work with any of these materials, it is extremely important to clean the tool using compressed air.

CHECK THE OIL LEVEL AT REGULAR INTERVALS

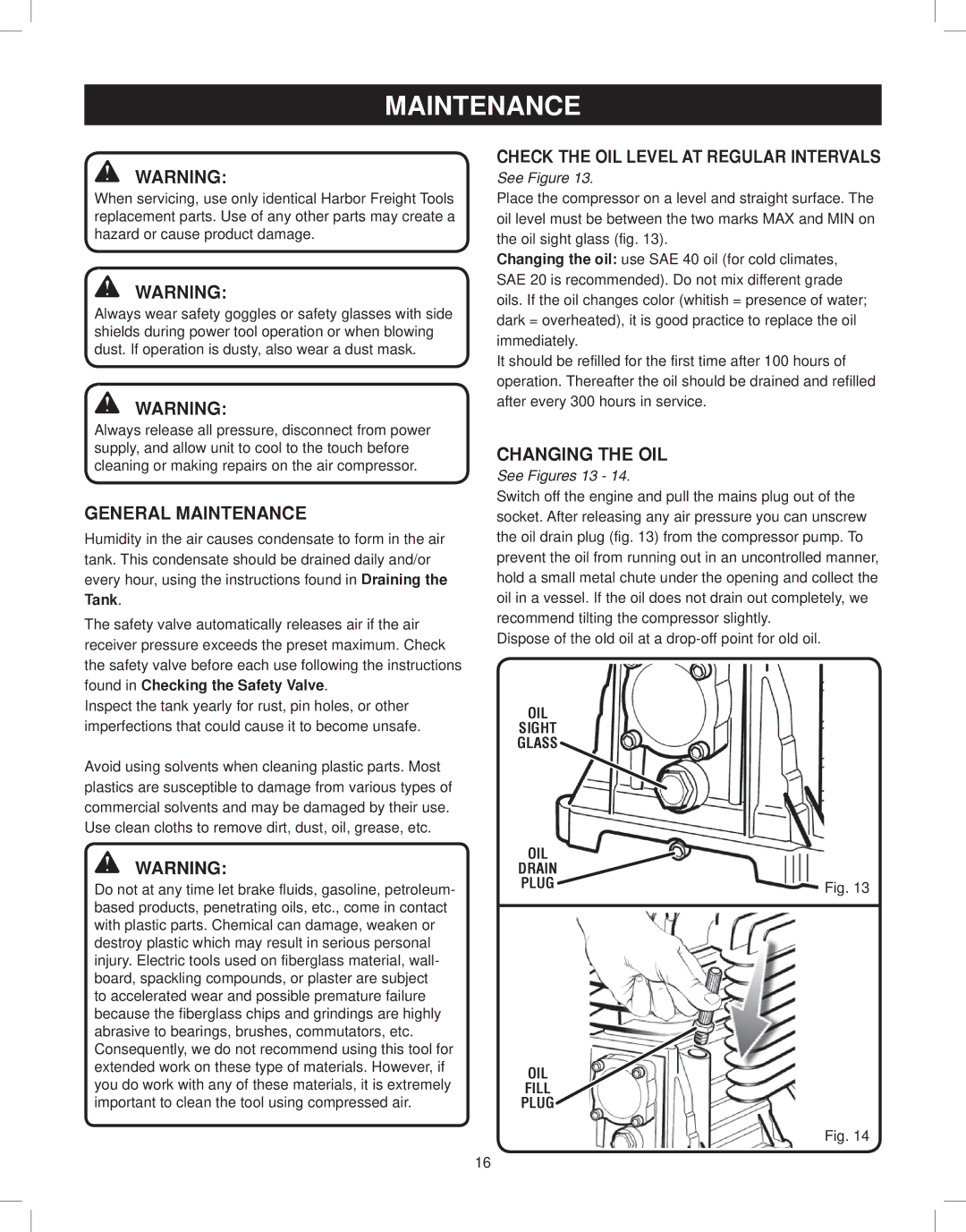

See Figure 13.

Place the compressor on a level and straight surface. The oil level must be between the two marks MAX and MIN on the oil sight glass (fig. 13).

Changing the oil: use SAE 40 oil (for cold climates, SAE 20 is recommended). Do not mix different grade oils. If the oil changes color (whitish = presence of water; dark = overheated), it is good practice to replace the oil immediately.

It should be refilled for the first time after 100 hours of operation. Thereafter the oil should be drained and refilled after every 300 hours in service.

CHANGING THE OIL

See Figures 13 - 14.

Switch off the engine and pull the mains plug out of the socket. After releasing any air pressure you can unscrew the oil drain plug (fig. 13) from the compressor pump. To prevent the oil from running out in an uncontrolled manner, hold a small metal chute under the opening and collect the oil in a vessel. If the oil does not drain out completely, we recommend tilting the compressor slightly.

Dispose of the old oil at a

OIL

SIGHT

GLASS

OIL |

|

DRAIN |

|

PLUG | Fig. 13 |

OIL

FILL

PLUG

Fig. 14

16