EIR102 Series Quick Start

Guide

EIR102

© 2008 by B&B Electronics. All rights reserved.

Package Contents

•EIR102 Series Industrial Media Converter

•Quick Start Guide (One per shipment)

•Power Terminal Block (installed)

•Fiber Optic Dust Covers (installed on fiber optic models)

If any item is missing or damaged, contact B&B Electronics for a replacement

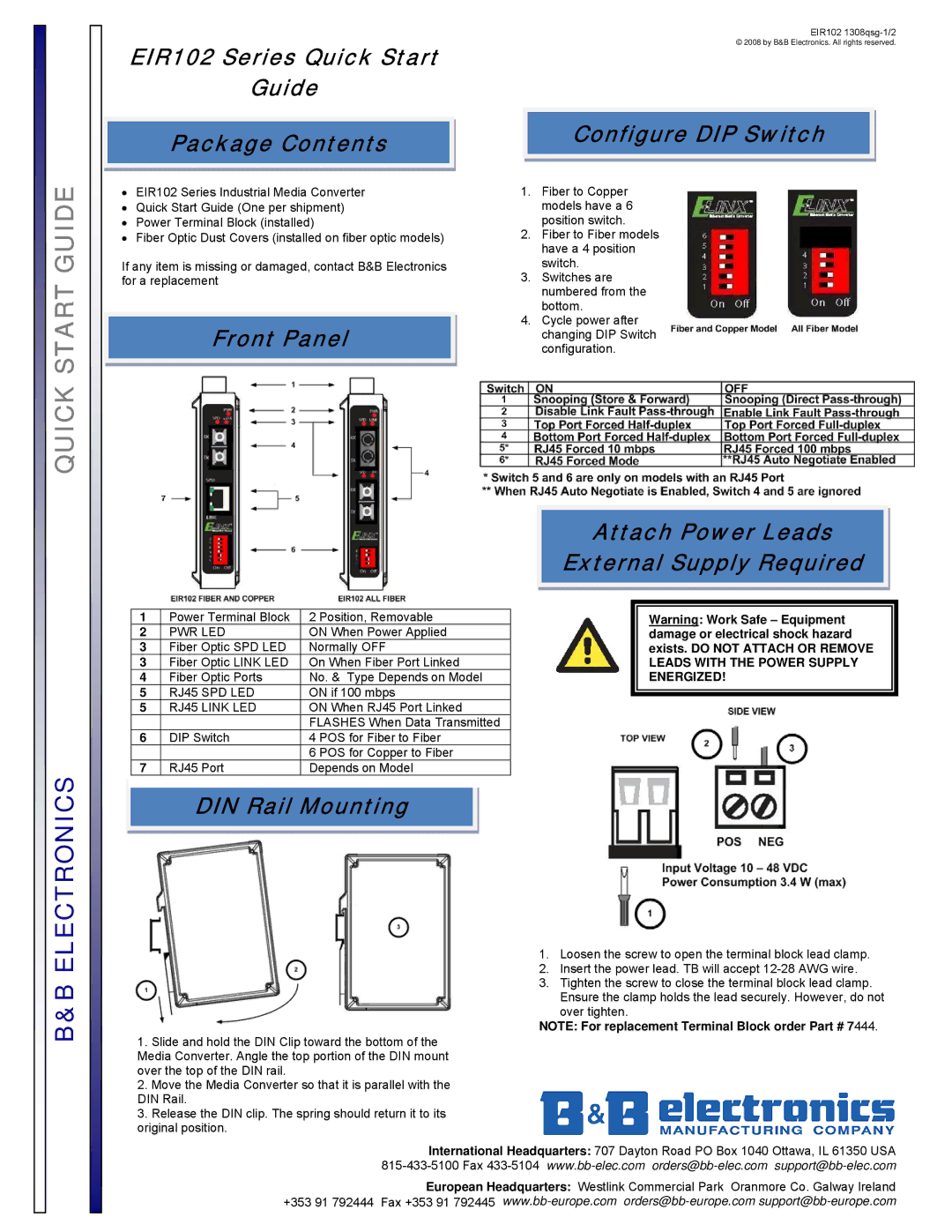

Front Panel

Configure DIP Switch

1.Fiber to Copper models have a 6 position switch.

2.Fiber to Fiber models have a 4 position switch.

3.Switches are numbered from the bottom.

4.Cycle power after changing DIP Switch configuration.

Attach Power Leads

External Supply Required

QUICK START GUIDE

B&B ELECTRONICS

|

|

|

|

|

|

| 1 | Power Terminal Block | 2 | Position, Removable |

|

| 2 | PWR LED | ON When Power Applied |

| |

| 3 | Fiber Optic SPD LED | Normally OFF |

| |

| 3 | Fiber Optic LINK LED | On When Fiber Port Linked |

| |

| 4 | Fiber Optic Ports | No. & Type Depends on Model |

| |

| 5 | RJ45 SPD LED | ON if 100 mbps |

| |

| 5 | RJ45 LINK LED | ON When RJ45 Port Linked |

| |

|

|

| FLASHES When Data Transmitted |

| |

| 6 | DIP Switch | 4 | POS for Fiber to Fiber |

|

|

|

| 6 | POS for Copper to Fiber |

|

| 7 | RJ45 Port | Depends on Model |

| |

|

|

|

|

|

|

DIN Rail Mounting

1.Slide and hold the DIN Clip toward the bottom of the Media Converter. Angle the top portion of the DIN mount over the top of the DIN rail.

2.Move the Media Converter so that it is parallel with the DIN Rail.

3.Release the DIN clip. The spring should return it to its original position.

Warning: Work Safe – Equipment damage or electrical shock hazard exists. DO NOT ATTACH OR REMOVE LEADS WITH THE POWER SUPPLY ENERGIZED!

1.Loosen the screw to open the terminal block lead clamp.

2.Insert the power lead. TB will accept

3.Tighten the screw to close the terminal block lead clamp. Ensure the clamp holds the lead securely. However, do not over tighten.

NOTE: For replacement Terminal Block order Part # 7444.

International Headquarters: 707 Dayton Road PO Box 1040 Ottawa, IL 61350 USA

European Headquarters: Westlink Commercial Park Oranmore Co. Galway Ireland