Section 6 • Electrical Systems

!DANGER

GASOLINE VAPORS CAN EXPLODE

Use ONLY

Do not use automotive parts for these components or any jumper cables because they are not ignition- protected and could cause a fire or explosion.

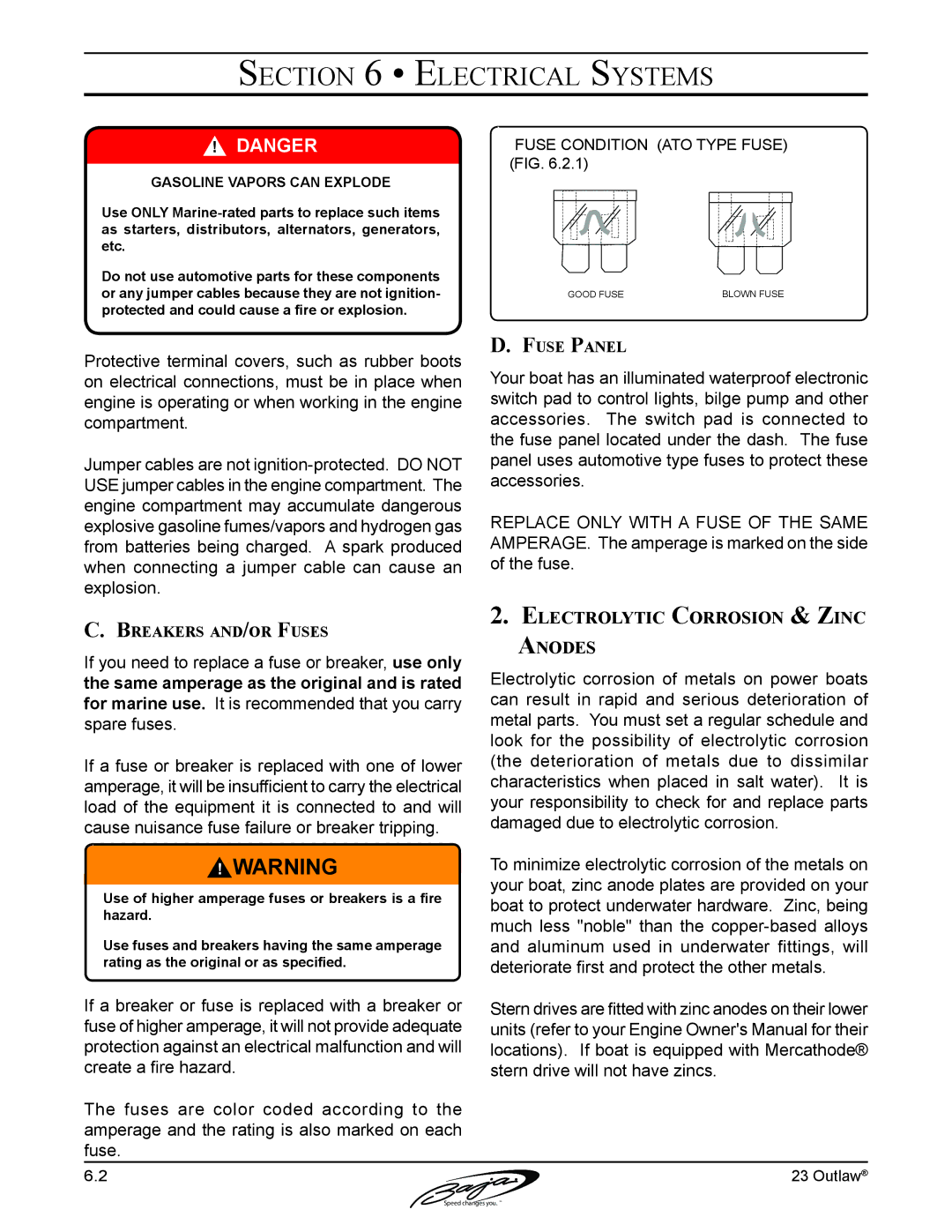

FUSE CONDITION (ATO TYPE FUSE) (FIG. 6.2.1)

GOOD FUSE | BLOWN FUSE |

Protective terminal covers, such as rubber boots on electrical connections, must be in place when engine is operating or when working in the engine compartment.

Jumper cables are not

C.Breakers and/or Fuses

If you need to replace a fuse or breaker, use only the same amperage as the original and is rated for marine use. It is recommended that you carry spare fuses.

If a fuse or breaker is replaced with one of lower amperage, it will be insufficient to carry the electrical load of the equipment it is connected to and will cause nuisance fuse failure or breaker tripping.

!WARNING

Use of higher amperage fuses or breakers is a fire hazard.

Use fuses and breakers having the same amperage rating as the original or as specified.

If a breaker or fuse is replaced with a breaker or fuse of higher amperage, it will not provide adequate protection against an electrical malfunction and will create a fire hazard.

The fuses are color coded according to the amperage and the rating is also marked on each fuse.

D.Fuse Panel

Your boat has an illuminated waterproof electronic switch pad to control lights, bilge pump and other accessories. The switch pad is connected to the fuse panel located under the dash. The fuse panel uses automotive type fuses to protect these accessories.

REPLACE ONLY WITH A FUSE OF THE SAME AMPERAGE. The amperage is marked on the side of the fuse.

2.Electrolytic Corrosion & Zinc Anodes

Electrolytic corrosion of metals on power boats can result in rapid and serious deterioration of metal parts. You must set a regular schedule and look for the possibility of electrolytic corrosion (the deterioration of metals due to dissimilar characteristics when placed in salt water). It is your responsibility to check for and replace parts damaged due to electrolytic corrosion.

To minimize electrolytic corrosion of the metals on your boat, zinc anode plates are provided on your boat to protect underwater hardware. Zinc, being much less "noble" than the

Stern drives are fitted with zinc anodes on their lower units (refer to your Engine Owner's Manual for their locations). If boat is equipped with Mercathode® stern drive will not have zincs.

6.2 | R |

23 Outlaw®

Speed changes you. TM.