DX81P6 specifications

The Banner DX81P6 is a versatile and robust industrial sensor designed for advanced automation applications. This device is known for its high precision and reliability, making it an essential component in various manufacturing processes. Its main features include a compact design, advanced sensing capabilities, and seamless integration with existing systems.One of the standout features of the DX81P6 is its high-resolution sensing technology. It employs sophisticated photoelectric sensors that can detect objects at varying distances and sizes, ensuring optimal performance in diverse environments. The device is equipped with multiple sensing modes, such as reflective, through-beam, and proximity sensing, allowing it to adapt to specific application requirements.

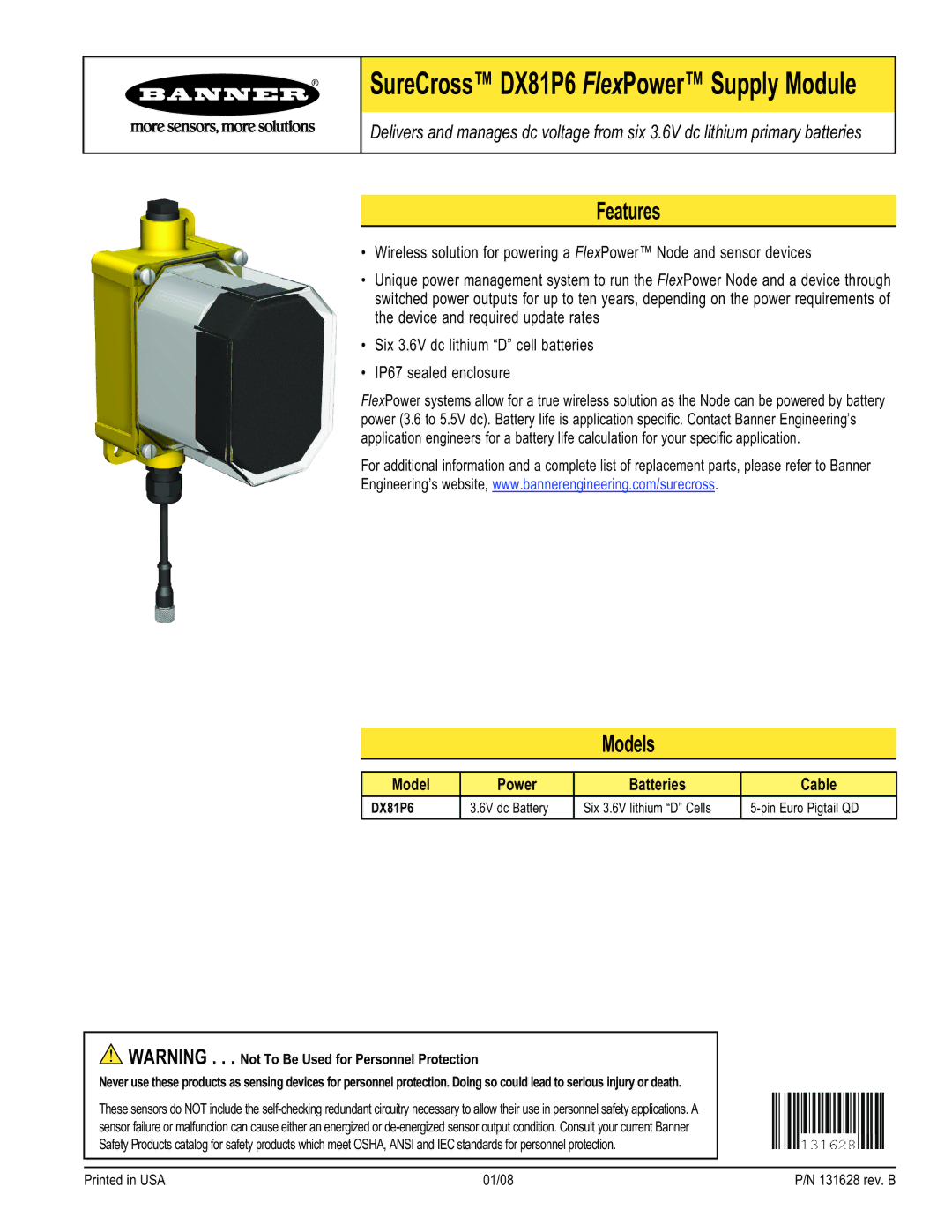

Additionally, the DX81P6 boasts a durable construction that can withstand harsh industrial conditions. It is rated IP67, meaning it is fully protected against dust ingress and can withstand temporary immersion in water. This robustness ensures that the sensor operates reliably even in challenging environments, such as those found in manufacturing and processing plants.

Another key characteristic of the DX81P6 is its user-friendly interface. The sensor features a simple setup process, allowing for quick installation and minimal downtime. With easy-to-read LED indicators, operators can monitor the sensor’s status at a glance, facilitating efficient operation and maintenance.

The DX81P6 also supports various communication protocols, including IO-Link. This enables seamless data exchange between the sensor and other devices in the automation ecosystem. By utilizing IO-Link technology, users can access detailed diagnostic information, enhancing troubleshooting capabilities and reducing unexpected equipment failures.

Furthermore, the DX81P6 is designed with energy efficiency in mind. It features low power consumption, which contributes to sustainable operation and cost savings for businesses. The sensor’s long lifespan and minimal maintenance needs further enhance its value, making it a cost-effective solution for various industries.

In conclusion, the Banner DX81P6 encapsulates innovation and reliability in industrial sensing. Its high-resolution sensing capabilities, durable construction, user-friendly interface, and advanced communication technologies make it a top choice for optimizing automation processes. Businesses can benefit significantly from implementing this sensor, driving efficiency and productivity in their operations.