PA13-SERIES PACKAGED AIR CONDITIONERS

Cooling Capacities: 23,000 to 56,000

SEER: 13.0

GREEN REFRIGERANT

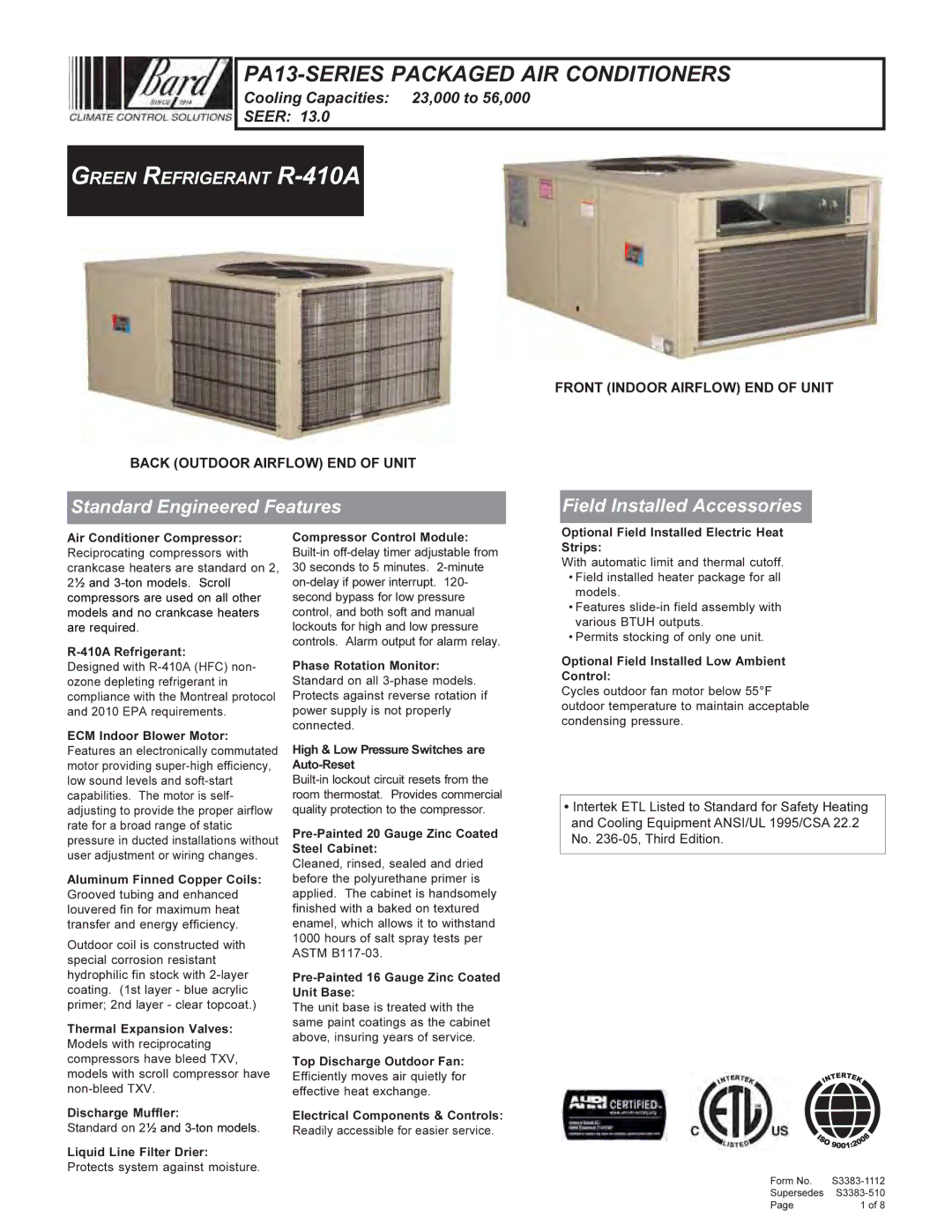

BACK (OUTDOOR AIRFLOW) END OF UNIT

Standard Engineered Features

FRONT (INDOOR AIRFLOW) END OF UNIT

Field Installed Accessories

Air Conditioner Compressor: Reciprocating compressors with crankcase heaters are standard on 2, 2½ and

Designed with

ECM Indoor Blower Motor: Features an electronically commutated motor providing

Aluminum Finned Copper Coils: Grooved tubing and enhanced louvered fin for maximum heat transfer and energy efficiency.

Outdoor coil is constructed with special corrosion resistant hydrophilic fin stock with

Thermal Expansion Valves: Models with reciprocating compressors have bleed TXV, models with scroll compressor have

Discharge Muffler:

Standard on 2½ and

Liquid Line Filter Drier: Protects system against moisture.

Compressor Control Module:

Phase Rotation Monitor: Standard on all

High & Low Pressure Switches are

Cleaned, rinsed, sealed and dried before the polyurethane primer is applied. The cabinet is handsomely finished with a baked on textured enamel, which allows it to withstand 1000 hours of salt spray tests per ASTM

The unit base is treated with the same paint coatings as the cabinet above, insuring years of service.

Top Discharge Outdoor Fan: Efficiently moves air quietly for effective heat exchange.

Electrical Components & Controls: Readily accessible for easier service.

Optional Field Installed Electric Heat

Strips:

With automatic limit and thermal cutoff.

•Field installed heater package for all models.

•Features

•Permits stocking of only one unit.

Optional Field Installed Low Ambient

Control:

Cycles outdoor fan motor below 55°F outdoor temperature to maintain acceptable condensing pressure.

•Intertek ETL Listed to Standard for Safety Heating and Cooling Equipment ANSI/UL 1995/CSA 22.2 No.

Form No. | |

Supersedes | |

Page | 1 of 8 |