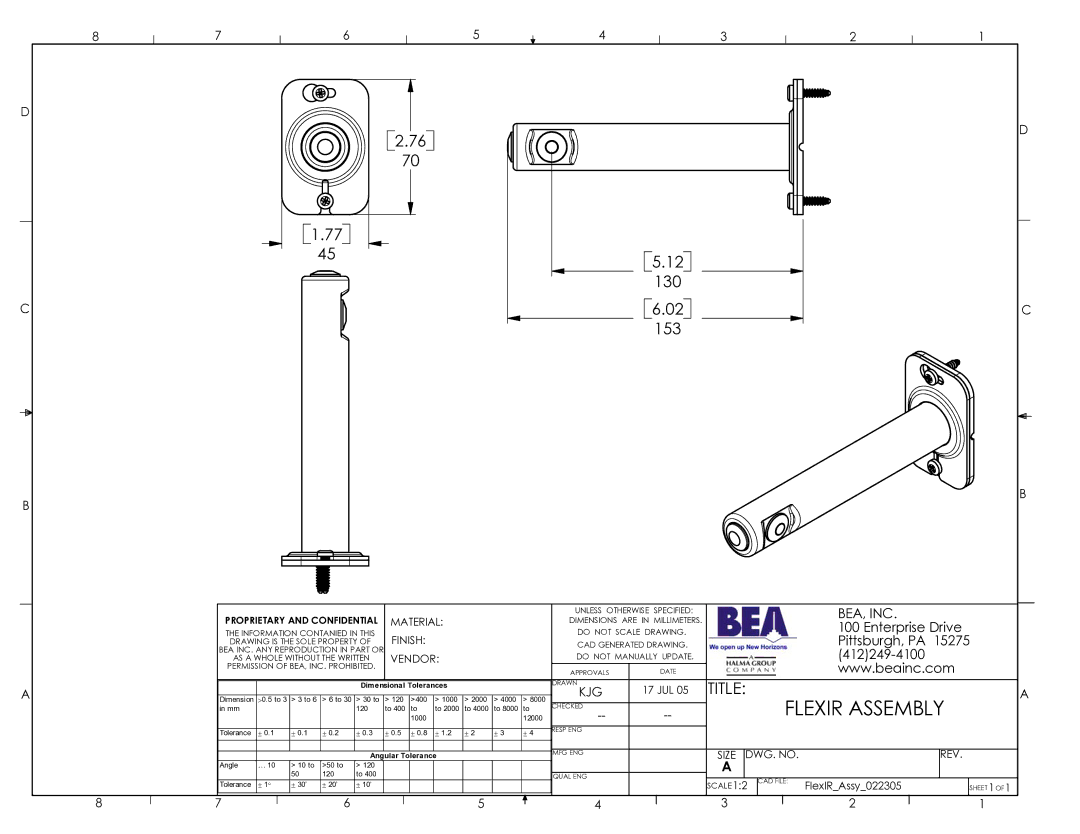

Flexir Assembly specifications

BEA Flexir Assembly is an innovative platform designed to optimize the assembly and production processes in various manufacturing environments. Its ability to enhance efficiency and adaptability makes it particularly valuable for companies facing changing market demands and the need for rapid product variations.One of the main features of BEA Flexir Assembly is its modular design. This allows manufacturers to customize their assembly lines by adding or removing components based on specific production needs. Such flexibility is essential in today’s fast-paced market, where customer preferences shift rapidly and manufacturers must respond quickly to maintain competitiveness.

The platform utilizes advanced automation technologies, including robotics and artificial intelligence, which enhance precision and speed in the assembly process. By integrating robotic arms and AI-driven systems, BEA Flexir Assembly minimizes human error and optimizes operational workflows, ensuring that assembly tasks are performed accurately and efficiently.

Another noteworthy characteristic of BEA Flexir Assembly is its real-time data analytics capability. By leveraging IoT (Internet of Things) technology, the platform collects data from various stages of the assembly process, allowing managers to monitor performance metrics continuously. This data can be analyzed to identify bottlenecks, improve resource allocation, and facilitate informed decision-making.

Interconnectivity is another critical feature of BEA Flexir Assembly. The platform supports seamless integration with existing ERP systems and other manufacturing software, facilitating a smooth flow of information across different departments. This interconnected approach ensures that all stakeholders, from production teams to supply chain managers, can access real-time insights, thus improving collaboration and overall operational efficiency.

The user interface of BEA Flexir Assembly is designed with ease of use in mind. Operators can easily navigate the system, making it simple to manage the assembly process and respond to any emerging issues quickly. This focus on user experience helps to reduce training time and enhances productivity on the shop floor.

In summary, BEA Flexir Assembly stands out due to its modular design, advanced automation technologies, real-time data analytics, interconnectivity, and user-friendly interface. These features collectively empower manufacturers to streamline their assembly operations, improve productivity, and adapt to the ever-evolving demands of the marketplace. As industries continue to embrace digital transformation, solutions like BEA Flexir Assembly will play a crucial role in shaping the future of manufacturing.