with the end of the brake actuator push rod. Install the retaining ring on the adapter bushing, making certain it is in the adapter bushing groove. Turn the ASA‑5® slack adjuster manual adjustment hex clockwise until the adapter bushing begins to enter the yoke. Fully compress the retaining ring “legs” and continue turning the ASA‑5® slack adjuster manual adjustment hex until the adapter bushing is completely in the yoke. Allow the retaining ring to expand into the corresponding groove in the yoke. Make certain the retaining ring is seated in both the yoke and the adapter bushing groove by manually pulling the ASA‑5® slack adjuster arm, attempting to separate the adapter bushing and yoke.

5.Run the brake actuator push rod jam nut down against the adapter or adapter bushing. Hold the adapter or adapter bushing hex with a wrench and tighten the jam nut to 300‑400 inch pounds for the 1/2"‑20 thread and 400‑600 inch pounds for the 5/8"‑18 thread.

6.Manually adjust the brakes.

Note: The vehicle brakes should be adjusted using the vehicle or brake manufacturer’s recommendation. If they are not available, the following procedure can be used: Rotate the manual adjustment hex clockwise until the linings are snug against the drum. Turn the adjustment hex counterclockwise 1/2 turn. Pull the actuator push rod to confirm that approximately 1/2 inch of push rod free stroke exists. Apply 85 psi and check that the push rod stroke is below the readjustment limit. If the stroke exceeds the readjustment limit, check the condition of the foundation brake. Refer to Brake Maintenance Inspection.

7.Manually uncage the spring brakes before returning the vehicle to service.

8.With the ASA‑5® slack adjuster installed, check to ensure clearance requirements with the brake fully released and at the actuator’s maximum stroke. Also consider clearances with the vehicle suspension springs depressed to the jounce bumpers, as well as in rebound.

PREVENTIVE MAINTENANCE

Important: Always review the Bendix Warranty Policy before performing any intrusive maintenance procedures. A warranty may be voided if intrusive maintenance is performed during the warranty period.

No two vehicles operate under identical conditions, as a result, maintenance intervals may vary. Experience is a valuable guide in determining the best maintenance interval for air brake system components. At a minimum, the

Visually check for physical damage such as broken air lines and broken or missing parts.

Every 25,000 miles, or 3 months, or 500 operating hours or at the time of routine vehicle chassis lubrication, whichever occurs first, the following steps should be followed (Also observe any shorter brake adjustment inspections or maintenance intervals specified by the vehicle manufacturer):

1.Lubricate the automatic slack adjuster through the lube fitting with a quality multipurpose chassis lubricant (N.L.G.I. Grade 2).

Lubricate the slack adjuster until clean lubricant flows from the grease relief opening in the boot.

2.Perform the In Service Inspection described in this manual.

IN SERVICE INSPECTION

1.Apply and release the vehicle brakes several times while observing the ASA‑5® slack adjuster. The ASA‑5® slack adjuster and brake actuator should move freely without binding or interference and should return to the full released position. Observe the looseness that exists between the yoke and adapter bushing and the yoke and link pins and their mating parts (yoke, body, link). Replace these parts if looseness appears excessive. Make certain the brake actuator push rod jam nut is tight against the yoke adapter.

2.Inspect the ASA‑5® slack adjuster for physical damage paying particular attention to the link, boot and yoke. Inspect for bent, broken, loose or misaligned brake actuator push rods and cracked or damaged brake actuator brackets. Repair or replace any components found to be damaged.

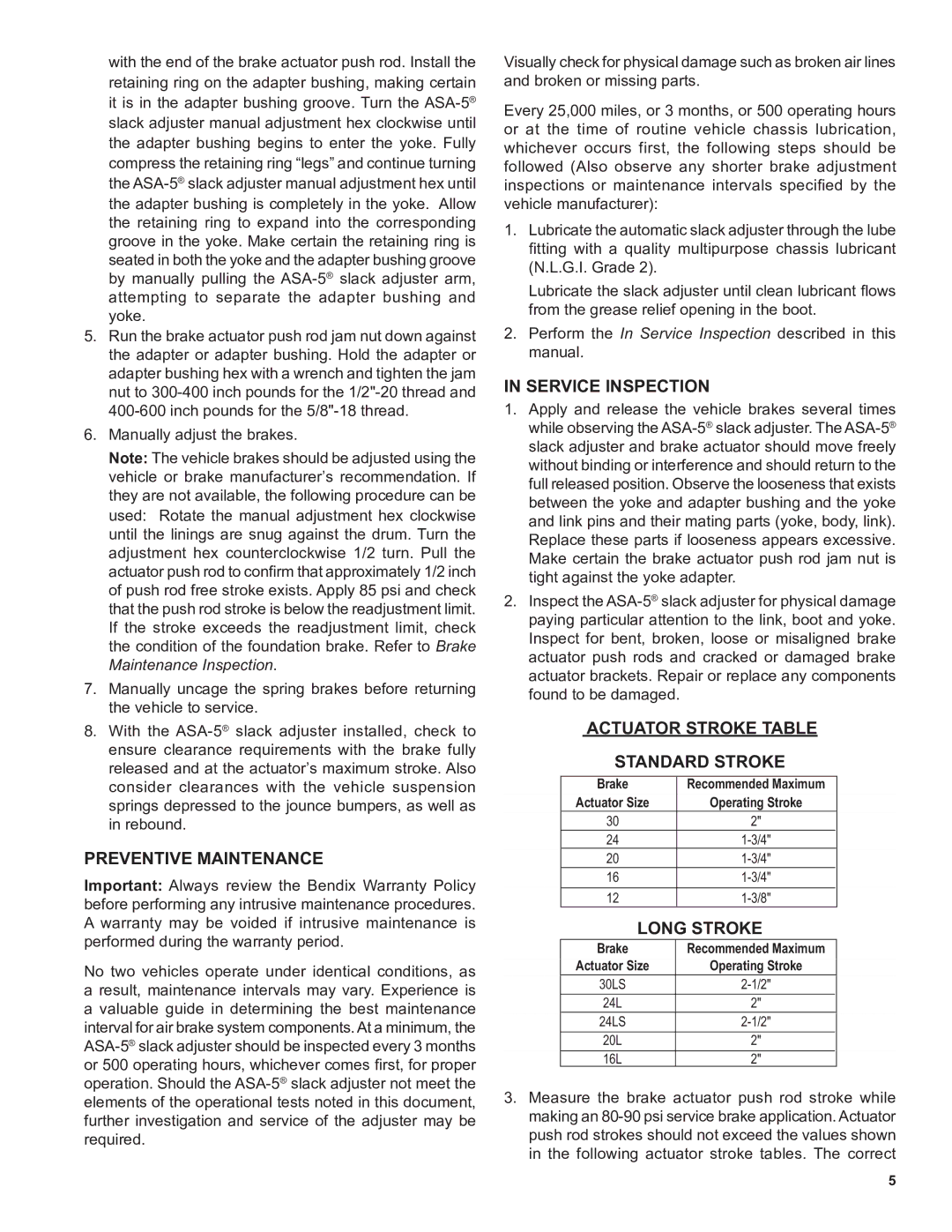

ACTUATOR STROKE TABLE

STANDARD STROKE

| Brake | Recommended Maximum |

|

| Actuator Size | Operating Stroke |

|

| 30 | 2" |

|

| 24 | 1‑3/4" |

|

| 20 | 1‑3/4" |

|

| 16 | 1‑3/4" |

|

|

|

|

|

| 12 | 1‑3/8" |

|

LONG STROKE

| Brake | Recommended Maximum |

|

| Actuator Size | Operating Stroke |

|

| 30LS |

| |

| 24L | 2" |

|

| 24LS |

| |

| 20L | 2" |

|

| 16L | 2" |

|

3.Measure the brake actuator push rod stroke while making an 80‑90 psi service brake application. Actuator push rod strokes should not exceed the values shown in the following actuator stroke tables. The correct

5