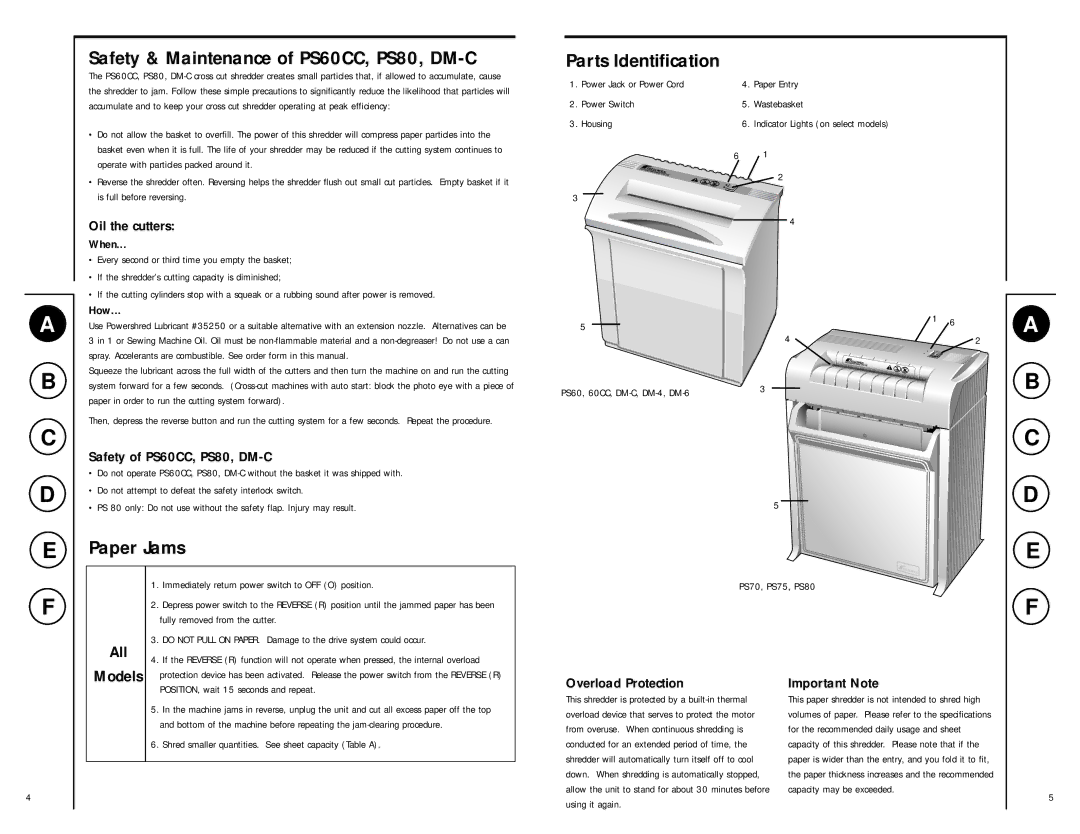

DM-4, DM-6, Ps60, Dm-c, Ps60cc, Dm-4, Ps70, Dm-6, Ps75, Ps80, PS60, PS75 specifications

Fellowes offers an extensive range of shredders designed to meet the diverse needs of home and office users. Among the popular models are the PS75, PS60, PS60cc, DM-C, PS70, DM-4, PS75, PS80, and DM-6. Each of these shredders comes with unique features and technologies aimed at enhancing document security and user convenience.The Fellowes PS75 shredder is equipped with a cross-cut mechanism that efficiently shreds up to 12 sheets of paper at once. Its compact design makes it perfect for home use, while the safety lock feature ensures that children cannot operate the machine unintentionally. The PS60 and PS60cc also serve similar needs but provide different capacities, allowing users to choose based on their shredding demands. The PS60cc model stands out with its 4-digit security code to protect confidential documents.

Moving on to the DM series, the DM-C and DM-4 shredders are built for more heavy-duty use, offering greater sheet capacities and durability. The DM-C can shred credit cards and staples, making it ideal for users with varied shredding needs. Moreover, the DM-4 includes the Fellowes patented Safety Lock technology, which helps prevent accidental operation, further enhancing safety.

The PS70 offers a blend of efficiency and user-friendly features, shredding up to 10 pages at a time with a quiet motor that minimizes distractions. The PS80 model takes shredding to the next level by incorporating a high-capacity bin that reduces the frequency of emptying, making it suitable for busy office environments.

Each shredder boasts the Fellowes SilentShred technology, ensuring a quieter operation, which is crucial in office settings. Furthermore, the Jam Blocker technology prevents paper jams by detecting and stopping the shredding process before a jam occurs.

All these models demonstrate Fellowes' commitment to providing high-quality shredding solutions with a focus on security and convenience. Whether you are an individual looking for a reliable home shredder or a business with higher-volume shredding needs, Fellowes has a suitable option to protect your sensitive information effectively.