Technical Bulletin

Bulletin No: | Effective Date: | Cancels: N/A | Page: 1 of 3 |

Subject: Bendix®

The Bendix®

| Metal |

|

Hard Seat | Black | Soft Seat |

Rubber |

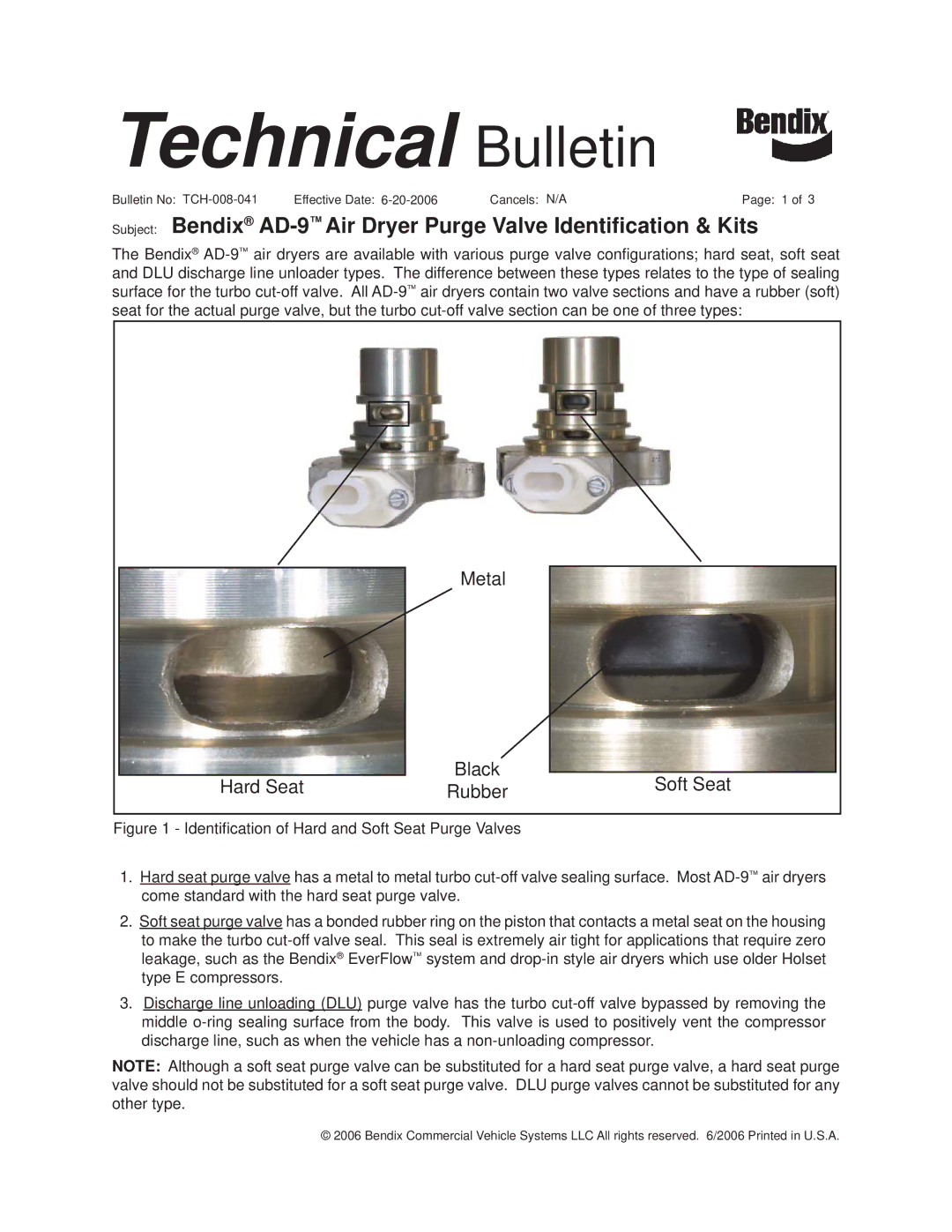

Figure 1 - Identification of Hard and Soft Seat Purge Valves

1.Hard seat purge valve has a metal to metal turbo cut-off valve sealing surface. Most AD-9™ air dryers come standard with the hard seat purge valve.

2.Soft seat purge valve has a bonded rubber ring on the piston that contacts a metal seat on the housing to make the turbo cut-off valve seal. This seal is extremely air tight for applications that require zero leakage, such as the Bendix® EverFlow™ system and drop-in style air dryers which use older Holset type E compressors.

3.Discharge line unloading (DLU) purge valve has the turbo cut-off valve bypassed by removing the middle o-ring sealing surface from the body. This valve is used to positively vent the compressor discharge line, such as when the vehicle has a non-unloading compressor.

NOTE: Although a soft seat purge valve can be substituted for a hard seat purge valve, a hard seat purge valve should not be substituted for a soft seat purge valve. DLU purge valves cannot be substituted for any other type.

© 2006 Bendix Commercial Vehicle Systems LLC All rights reserved. 6/2006 Printed in U.S.A.