FM Owner’s Manual

MAINTENANCE

PERIODIC MAINTENANCE

Periodic maintenance should be performed at the following intervals:

Maintenance Operation | Every Use (daily) | Every 5 hrs or (daily) | Every 25 Hrs | Every 50 Hrs | Every 200 Hrs |

|

|

|

|

|

|

Inspect for loose, worn or damaged parts. | z |

|

|

|

|

|

|

|

|

|

|

Check for excessive vibration |

| z |

|

|

|

|

|

|

|

|

|

Inspect belt for wear |

|

| z |

|

|

|

|

|

|

|

|

Engine (See Engine Manual) |

|

|

|

|

|

|

|

|

|

|

|

Grease caster pivot points and lubricate height |

|

| z |

|

|

adjustment spacers |

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|

|

Sharpen Blade |

|

| z |

|

|

|

|

|

|

|

|

Lubricate pivot points of all three control levers |

|

| z |

|

|

|

|

|

|

|

|

Check tire pressure |

|

|

|

|

|

Note: inflate to mfr.’s specs. as shown on tire |

|

| z |

|

|

side wall |

|

|

|

|

|

|

|

|

|

|

|

Check brake puck |

|

|

| z |

|

|

|

|

|

|

|

Check parking brake |

|

|

| z |

|

|

|

|

|

|

|

Replace blade and traction belts |

|

|

|

| z |

|

|

|

|

|

|

Note: Blade, blade brake puck, transaxle brake, and drive belts are normal wear items. These should be inspected on a regular basis and replaced if worn.

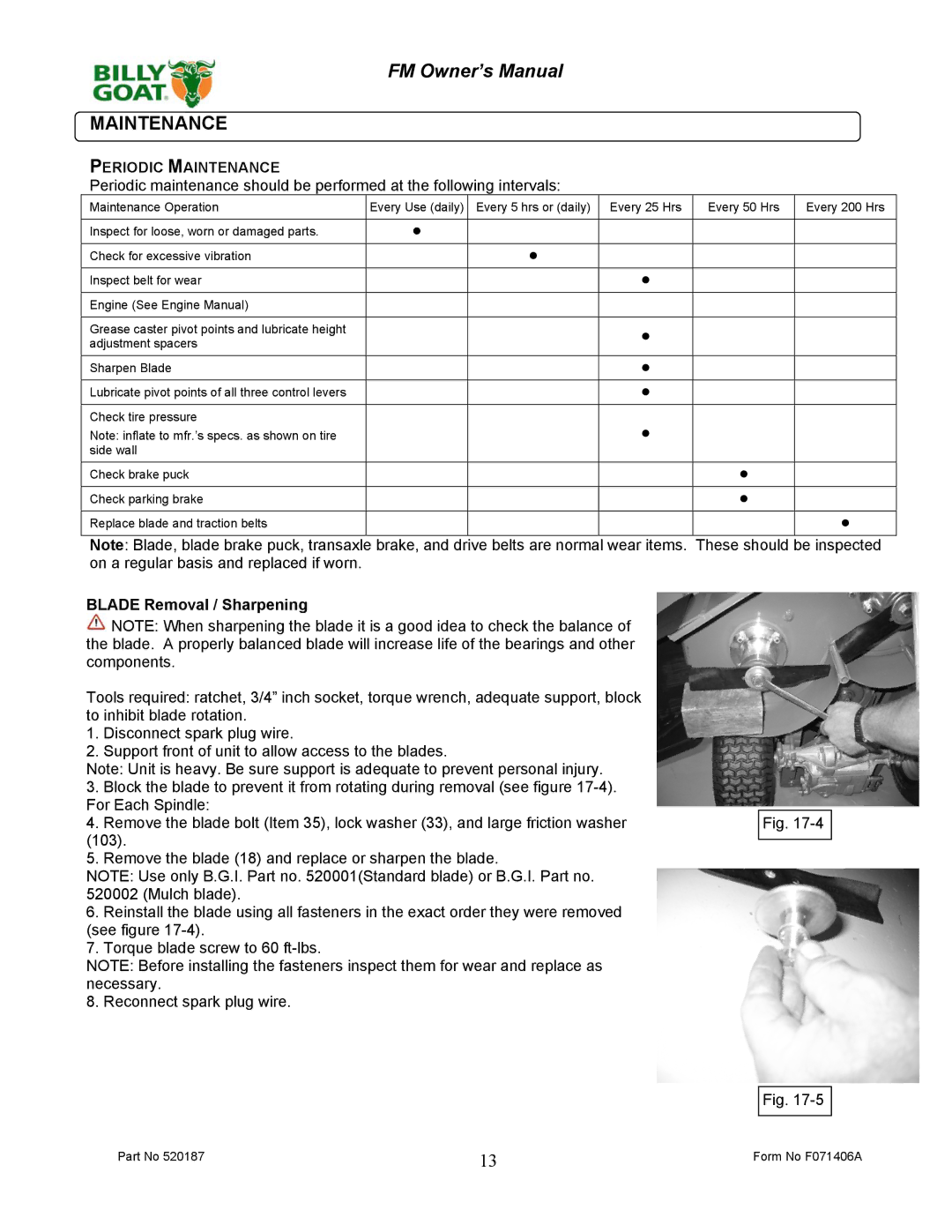

BLADE Removal / Sharpening

![]() NOTE: When sharpening the blade it is a good idea to check the balance of the blade. A properly balanced blade will increase life of the bearings and other components.

NOTE: When sharpening the blade it is a good idea to check the balance of the blade. A properly balanced blade will increase life of the bearings and other components.

Tools required: ratchet, 3/4” inch socket, torque wrench, adequate support, block to inhibit blade rotation.

1. Disconnect spark plug wire.

2. Support front of unit to allow access to the blades.

Note: Unit is heavy. Be sure support is adequate to prevent personal injury.

3.Block the blade to prevent it from rotating during removal (see figure

4.Remove the blade bolt (Item 35), lock washer (33), and large friction washer (103).

5.Remove the blade (18) and replace or sharpen the blade.

NOTE: Use only B.G.I. Part no. 520001(Standard blade) or B.G.I. Part no. 520002 (Mulch blade).

6.Reinstall the blade using all fasteners in the exact order they were removed (see figure

7.Torque blade screw to 60

NOTE: Before installing the fasteners inspect them for wear and replace as necessary.

8.Reconnect spark plug wire.

Fig.

Fig.

Part No 520187 | 13 | Form No F071406A |