PR600S, OS551H, OS600S, PR500HT, OS551 specifications

The Billy Goat brand is renowned for its durable and efficient outdoor power equipment, particularly in the realm of leaf blowers, vacuums, and brush cutters. Among the standout offerings are the OS551H, PR600S, OS551, OS600S, and PR500HT models, each designed to tackle specific tasks with efficiency and ease.The OS551H is a powerful outdoor clean-up tool featuring a robust Honda engine that ensures high performance and reliability. With its innovative design, this model offers excellent maneuverability and is perfect for tackling large areas with leaves and debris. The OS551H also boasts a debris management system that allows users to effectively collect and mulch leaves, making it a favorite among landscaping professionals.

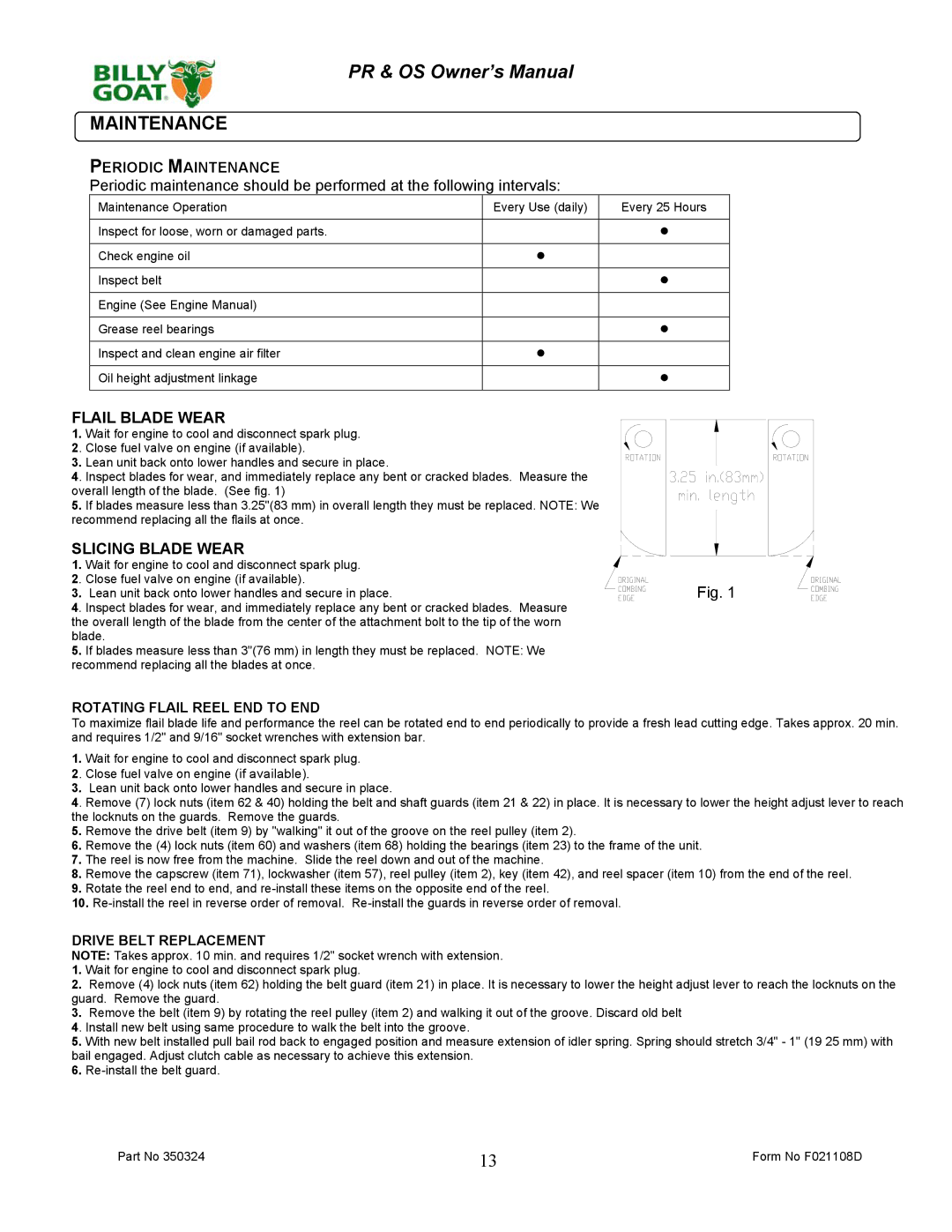

The PR600S is a versatile and user-friendly power rake. It is built to effortlessly remove thatch and promote healthy lawn growth. With adjustable height settings, the PR600S accommodates various turf types and conditions. Its powerful engine and durable construction make it an ideal choice for homeowners and professionals seeking to enhance lawn health and aesthetics.

Meanwhile, the OS551 model features a robust blower designed for clearing debris effectively. Its compact design allows for easy operation in tight spaces, making it suitable for both residential and commercial use. Additionally, it employs advanced noise-reduction technology, ensuring quieter operation while still maintaining powerful air output.

The OS600S is an upgraded version of its predecessor with an enhanced airspeed capacity, allowing it to move large volumes of air efficiently. This model is particularly advantageous for heavy-duty clean-up tasks, such as clearing thick leaves or debris after storms. The ergonomic design ensures operator comfort during extended use, reducing fatigue and enhancing productivity.

Lastly, the PR500HT is a high-performance power rake optimized for heavy-duty lawn care. It incorporates advanced features such as adjustable rake depth and high-speed operation, allowing it to tackle thick thatch effectively. The PR500HT is designed for both ease of use and longevity, making it a preferred tool among lawn care enthusiasts and professionals alike.

In conclusion, Billy Goat’s OS551H, PR600S, OS551, OS600S, and PR500HT models reflect a commitment to quality, efficiency, and user-friendliness. Whether for residential or commercial applications, these machines offer the technology and durability needed to meet various outdoor maintenance challenges.