QB1601, QB1601SP specifications

The Billy Goat QB1601 and QB1601SP are advanced commercial-grade quick-attach blowers designed to deliver unmatched performance and efficiency in outdoor clean-up tasks. These models excel in managing debris in demanding environments, making them perfect for landscapers, contractors, and property maintenance teams.At the heart of both models is a powerful 160cc engine that ensures robust performance. This engine not only provides ample power for efficient debris clearing but also operates at lower emissions levels, aligning with regulatory standards while minimizing environmental impact. The lightweight design of the QB1601 and QB1601SP models allows operators to maneuver with ease, reducing fatigue during long work hours.

One of the standout features of these blowers is their innovative air intake system. Incorporating a large, durable air filter, the QB1601 and QB1601SP are equipped to handle dust and debris, ensuring the engine runs smoothly for extended periods. The blowers also feature a unique vacuum and mulching system that allows users to switch between blowing and vacuuming modes effortlessly. This versatility significantly enhances productivity, as it enables operators to handle different tasks without needing multiple machines.

The QB1601 model is designed to offer a comfortable user experience, boasting ergonomically designed handles that reduce vibration and provide a secure grip. This thoughtful design translates to improved control and precision during operation. Moreover, the unit's compact size ensures easy storage and transport, making it a practical choice for professionals on the go.

In contrast, the QB1601SP model introduces a self-propelled feature, allowing for greater ease in operation over uneven terrains. This makes it particularly advantageous for expansive properties or areas with challenging landscapes. The self-propelled drive system provides added speed and efficiency, enabling users to cover larger areas in less time while maintaining consistent blowing power.

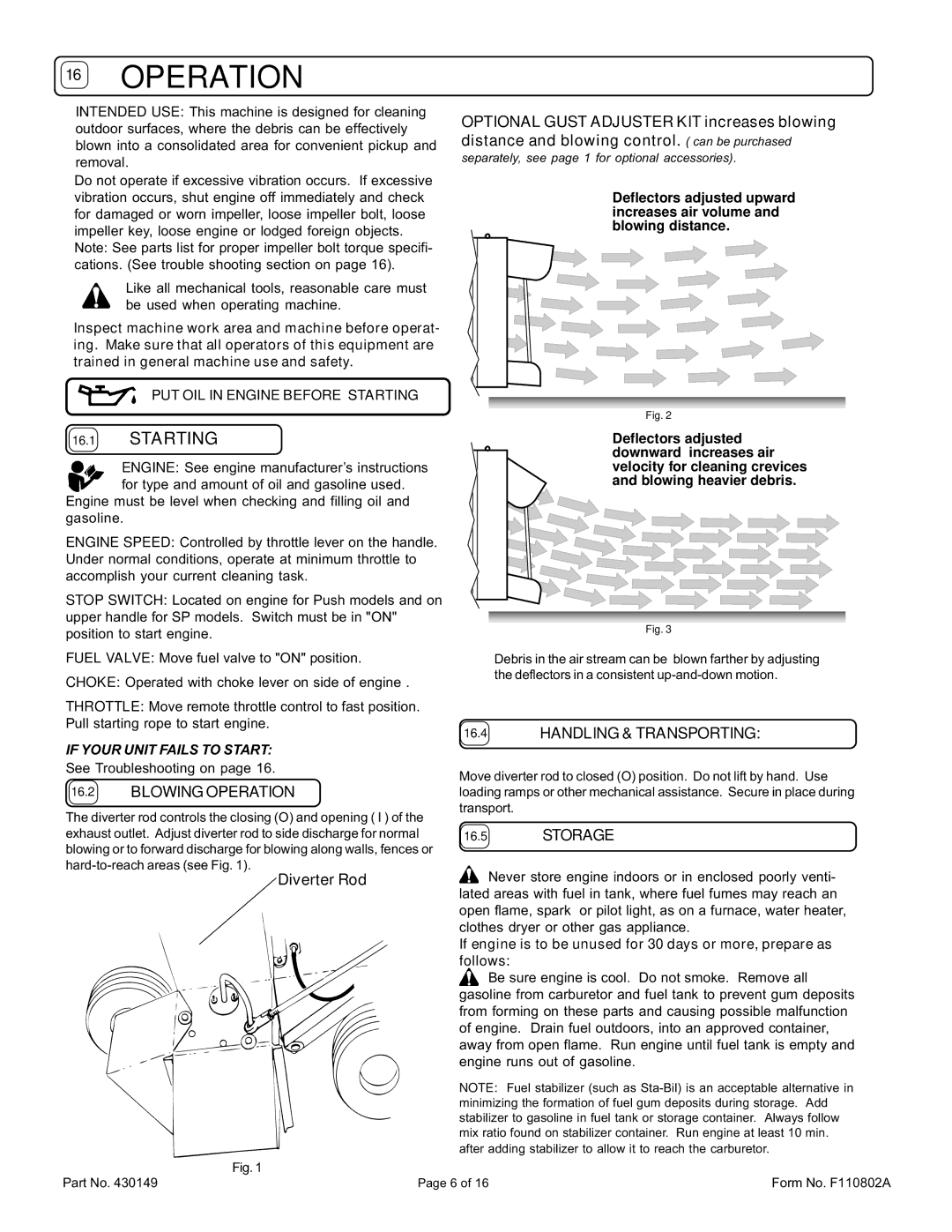

Both models come with a variety of nozzle attachments, allowing the user to customize airflow to suit different tasks—whether it's tackling leaves, grass clippings, or heavier debris. The adjustable airflow speed settings also give operators greater control, ensuring they can meet specific cleanup requirements effectively.

In summary, the Billy Goat QB1601 and QB1601SP are exemplary outdoor blowers that feature robust engines, innovative air intake systems, comfortable handling designs, and versatile attachments. These machines are engineered to provide high efficiency, durability, and user comfort, making them indispensable tools for any outdoor maintenance professional.