17MAINTENANCE

Use only a qualified mechanic for any adjustments, disassembly or any kind of repair .

WARNING: TO AVOID PERSONAL INJURY, ALWAYS

TURN MACHINE OFF, MAKE SURE ALL MOVING

PARTS COME TO A COMPLETE STOP.

DISCONNECT SPARK PLUG WIRE

BEFORE SERVICING UNIT.

ENGINE: See engine manufacturer operator's instructions.

RECONNECT SPARK PLUG WIRE AND

GUARDS BEFORE STARTING ENGINE.

17.1

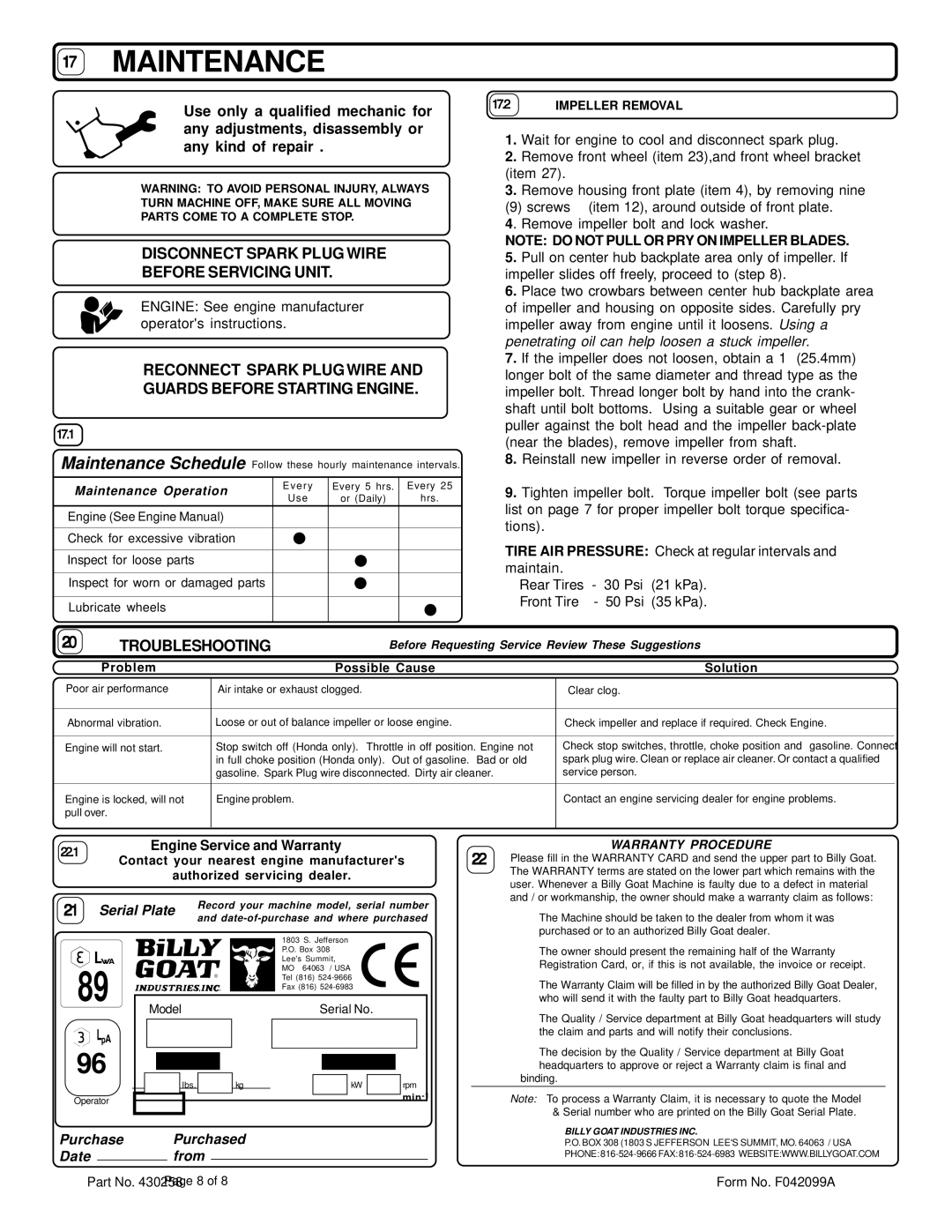

Maintenance Schedule Follow these hourly maintenance intervals.

17.2IMPELLER REMOVAL

1.Wait for engine to cool and disconnect spark plug.

2.Remove front wheel (item 23),and front wheel bracket (item 27).

3.Remove housing front plate (item 4), by removing nine

(9) screws (item 12), around outside of front plate.

4. Remove impeller bolt and lock washer.

NOTE: DO NOT PULL OR PRY ON IMPELLER BLADES.

5.Pull on center hub backplate area only of impeller. If impeller slides off freely, proceed to (step 8).

6.Place two crowbars between center hub backplate area of impeller and housing on opposite sides. Carefully pry impeller away from engine until it loosens. Using a penetrating oil can help loosen a stuck impeller.

7.If the impeller does not loosen, obtain a 1” (25.4mm) longer bolt of the same diameter and thread type as the impeller bolt. Thread longer bolt by hand into the crank- shaft until bolt bottoms. Using a suitable gear or wheel puller against the bolt head and the impeller

8.Reinstall new impeller in reverse order of removal.

Maintenance Operation | Every | Every 5 hrs. | Every 25 |

| 9. Tighten impeller bolt. Torque impeller bolt (see parts | |||||||||

Use | or (Daily) | hrs. | ||||||||||||

|

|

|

| list on page 7 for proper impeller bolt torque specifica- | ||||||||||

Engine (See Engine Manual) |

|

|

|

| ||||||||||

|

|

|

| tions). |

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Check for excessive vibration |

|

|

|

|

|

|

|

|

| |||||

|

|

|

| TIRE AIR PRESSURE: Check at regular intervals and | ||||||||||

|

|

|

|

|

|

|

| |||||||

Inspect for loose parts |

|

|

|

|

|

| ||||||||

|

|

|

|

|

| maintain. |

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| |||

Inspect for worn or damaged parts |

|

|

|

| Rear Tires | - | 30 Psi | (21 kPa). | ||||||

|

|

|

|

|

|

|

| Front Tire | - | 50 Psi | (35 kPa). | |||

Lubricate wheels |

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||

20 | TROUBLESHOOTING |

|

|

| ||||||||||

| Before Requesting Service Review These Suggestions | |||||||||||||

| Problem |

|

|

| Possible Cause |

|

|

|

| Solution | ||||

Poor air performance |

| Air intake or exhaust clogged. |

|

|

| Clear clog. |

|

| ||||||

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

| |||||

Abnormal vibration. |

| Loose or out of balance impeller or loose engine. |

| Check impeller and replace if required. Check Engine. | ||||||||||

|

|

|

|

|

|

|

|

| ||||||

Engine will not start. |

| Stop switch off (Honda only). Throttle in off position. Engine not | Check stop switches, throttle, choke position and gasoline. Connect | |||||||||||

|

|

| in full choke position (Honda only). Out of gasoline. Bad or old | spark plug wire. Clean or replace air cleaner. Or contact a qualified | ||||||||||

|

|

| gasoline. Spark Plug wire disconnected. Dirty air cleaner. |

| service person. |

|

| |||||||

|

|

|

|

|

|

|

|

|

| |||||

Engine is locked, will not |

| Engine problem. |

|

|

|

| Contact an engine servicing dealer for engine problems. | |||||||

pull over. |

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

22.1 |

| Engine Service and Warranty |

| |||

| Contact your nearest engine manufacturer's | |||||

|

| |||||

|

| authorized servicing dealer. |

| |||

21 | Serial Plate | Record your machine model, serial number | ||||

and | ||||||

|

|

| ||||

|

|

|

| 1803 S. Jefferson |

| |

| L A |

|

| P.O. Box 308 |

| |

|

|

| Lee's Summit, |

| ||

89 |

|

| MO 64063 / USA |

| ||

| R | Tel (816) |

| |||

|

|

|

| Fax (816) |

| |

|

| Model |

| Serial No. |

| |

96 | Unit(Weight) | Engine Power |

| |||

|

|

| ||||

|

| lbs. | kg | kW | rpm | |

Operator |

|

|

| |||

|

|

|

| |||

Purchase Purchased

Datefrom

WARRANTY PROCEDURE

22Please fill in the WARRANTY CARD and send the upper part to Billy Goat. The WARRANTY terms are stated on the lower part which remains with the user. Whenever a Billy Goat Machine is faulty due to a defect in material and / or workmanship, the owner should make a warranty claim as follows:

The Machine should be taken to the dealer from whom it was purchased or to an authorized Billy Goat dealer.

The owner should present the remaining half of the Warranty Registration Card, or, if this is not available, the invoice or receipt.

The Warranty Claim will be filled in by the authorized Billy Goat Dealer, who will send it with the faulty part to Billy Goat headquarters.

The Quality / Service department at Billy Goat headquarters will study the claim and parts and will notify their conclusions.

The decision by the Quality / Service department at Billy Goat headquarters to approve or reject a Warranty claim is final and

binding.

Note: To process a Warranty Claim, it is necessary to quote the Model

&Serial number who are printed on the Billy Goat Serial Plate.

BILLY GOAT INDUSTRIES INC.

P.O. BOX 308 (1803 S JEFFERSON LEE'S SUMMIT, MO. 64063 / USA PHONE:

Page 8 of 8 | Form No. F042099A |

Part No. 430258 |