16Operation

INTENDED USE: This machine is designed for vacuuming leaves, grass clippings and other types of organic litter and for chipping brush, limbs, corn and sunflower stalks and palm fronds.

Debris mixed with cans, bottles and small amounts of sand can be vacuumed; however, it is not this machine's primary purpose. Vacuuming cans, bottles and sand will affect the

Nozzle Height Fine Adjustment For Hard Surface Use: Optimum nozzle height is 1/2" (12.7mm) above ground with engine not running. To adjust height, loosen screws (item 37), on quad plate. Prop front of nozzle up 1.0" (25.4mm) above ground. Keeping wheels on ground,

longevity of your machine.

Do not operate if excessive vibration occurs. If excessive vibration occurs, shut engine off immediately and check for damaged or worn impeller, loose impeller bolt, loose impeller key, loose engine or lodged foreign objects. Note: See parts list for proper impeller bolt torque specifications. (See trouble shooting section on page 12).

Adjustment

Lowers

Nozzle

Rod In

First Hole

(fig. 1)

![]() Item 37 Ref. Securely Tighten, postion slots toward unit. Can be reversed to provide better hole alignment if required.

Item 37 Ref. Securely Tighten, postion slots toward unit. Can be reversed to provide better hole alignment if required.

Adjustment

Raises Nozzle

Like all mechanical tools, reasonable care must be used when operating machine.

Inspect machine work area and machine before operat- ing. Make sure that all operators of this equipment are trained in general machine use and safety.

PUT OIL IN ENGINE BEFORE STARTING.

16.7CHIPPING OPERATION

Wearing Eye Protection and Durable Gloves is recommended while operating chipper.

Use caution when using chipper

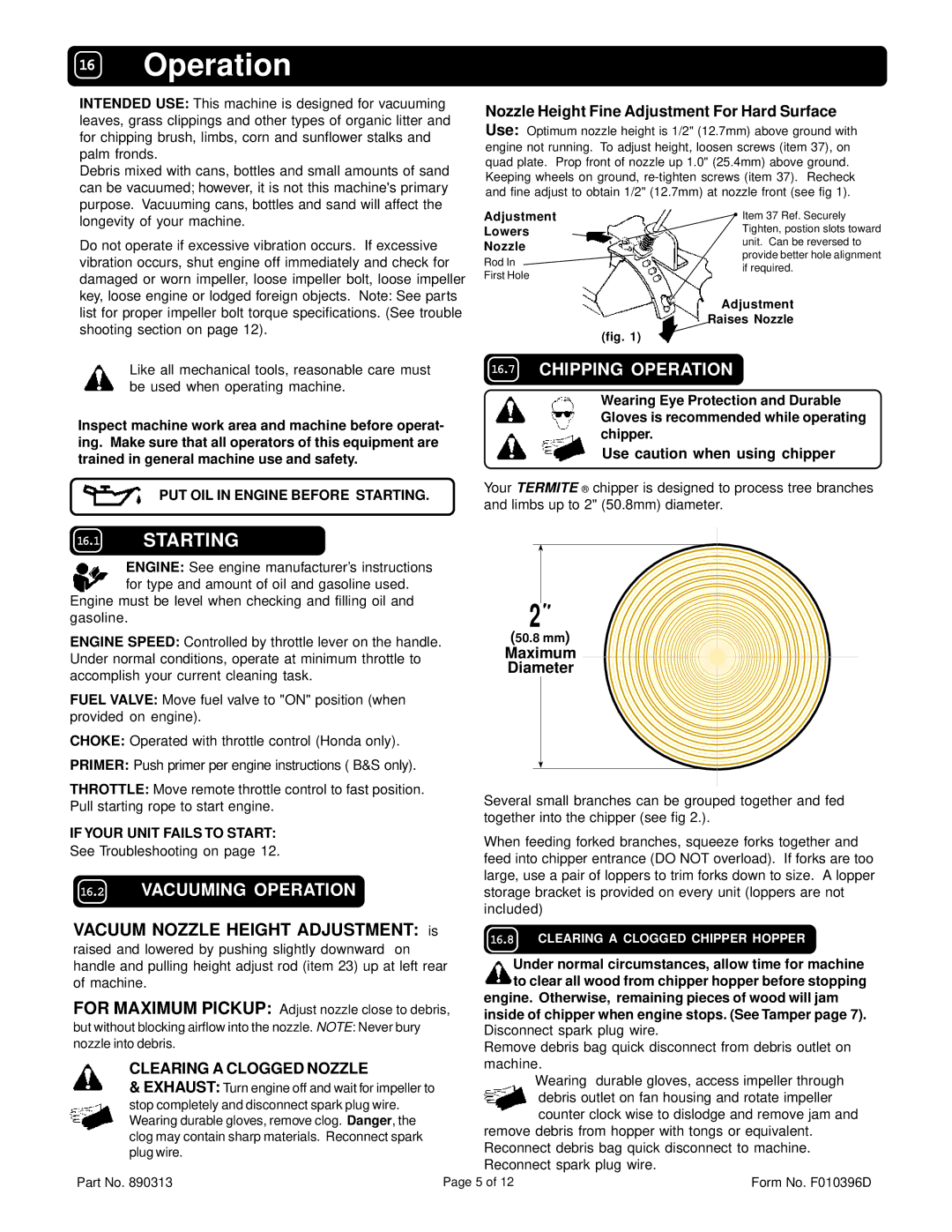

Your TERMITE ® chipper is designed to process tree branches and limbs up to 2" (50.8mm) diameter.

16.1STARTING

ENGINE: See engine manufacturer’s instructions for type and amount of oil and gasoline used.

Engine must be level when checking and filling oil and gasoline.

ENGINE SPEED: Controlled by throttle lever on the handle. Under normal conditions, operate at minimum throttle to accomplish your current cleaning task.

FUEL VALVE: Move fuel valve to "ON" position (when provided on engine).

CHOKE: Operated with throttle control (Honda only).

PRIMER: Push primer per engine instructions ( B&S only).

THROTTLE: Move remote throttle control to fast position. Pull starting rope to start engine.

IF YOUR UNIT FAILS TO START:

See Troubleshooting on page 12.

16.2VACUUMING OPERATION

VACUUM NOZZLE HEIGHT ADJUSTMENT: is

raised and lowered by pushing slightly downward on handle and pulling height adjust rod (item 23) up at left rear of machine.

FOR MAXIMUM PICKUP: Adjust nozzle close to debris,

but without blocking airflow into the nozzle. NOTE: Never bury nozzle into debris.

CLEARING A CLOGGED NOZZLE

&EXHAUST: Turn engine off and wait for impeller to stop completely and disconnect spark plug wire. Wearing durable gloves, remove clog. Danger, the clog may contain sharp materials. Reconnect spark plug wire.

2

(50.8 mm) Maximum Diameter

Several small branches can be grouped together and fed together into the chipper (see fig 2.).

When feeding forked branches, squeeze forks together and feed into chipper entrance (DO NOT overload). If forks are too large, use a pair of loppers to trim forks down to size. A lopper storage bracket is provided on every unit (loppers are not included)

16.8CLEARING A CLOGGED CHIPPER HOPPER

Under normal circumstances, allow time for machine to clear all wood from chipper hopper before stopping

engine. Otherwise, remaining pieces of wood will jam inside of chipper when engine stops. (See Tamper page 7).

Disconnect spark plug wire.

Remove debris bag quick disconnect from debris outlet on machine.

Wearing durable gloves, access impeller through debris outlet on fan housing and rotate impeller counter clock wise to dislodge and remove jam and

remove debris from hopper with tongs or equivalent. Reconnect debris bag quick disconnect to machine. Reconnect spark plug wire.

Part No. 890313 | Page 5 of 12 | Form No. F010396D |