TR1204L specifications

The Billy Goat TR1204L is a highly regarded debris loader that stands out in the landscaping and grounds maintenance industry. Designed for efficiency and ease of use, this compact yet powerful vacuuming machine is perfect for professional landscapers, contractors, and anyone in need of serious cleanup capabilities.One of the key features of the TR1204L is its robust 29 HP Briggs & Stratton Vanguard engine. This powerful engine provides the necessary muscle for tackling tough debris loads, whether it's leaves, grass clippings, or other yard waste. The engine is paired with a quick-attach discharge hose that enables operators to easily switch between collection and discharge modes, maximizing productivity.

The TR1204L is equipped with a 12-inch diameter, high-density polyethylene impeller that ensures efficient airflow and material breakdown. The impeller design allows for superior suction power, making it easy to pick up large volumes of debris without clogging. Additionally, the vacuum is designed with a unique "Easy-Pull" feature, which allows users to easily maneuver and position the machine with minimal effort, enhancing the overall user experience.

Another notable characteristic is the machine's large capacity debris collection bag, which significantly reduces the need for frequent emptying during operation. The bag can hold up to 340 gallons, allowing for extended use in larger landscapes or commercial properties without interruption. The TR1204L also features a convenient dump mechanism that makes emptying the bag quick and effortless.

The design of the Billy Goat TR1204L prioritizes operator comfort with features such as an adjustable handle, which allows users to customize the height for better control and ergonomics. The low center of gravity enhances stability, further improving handling on uneven terrains.

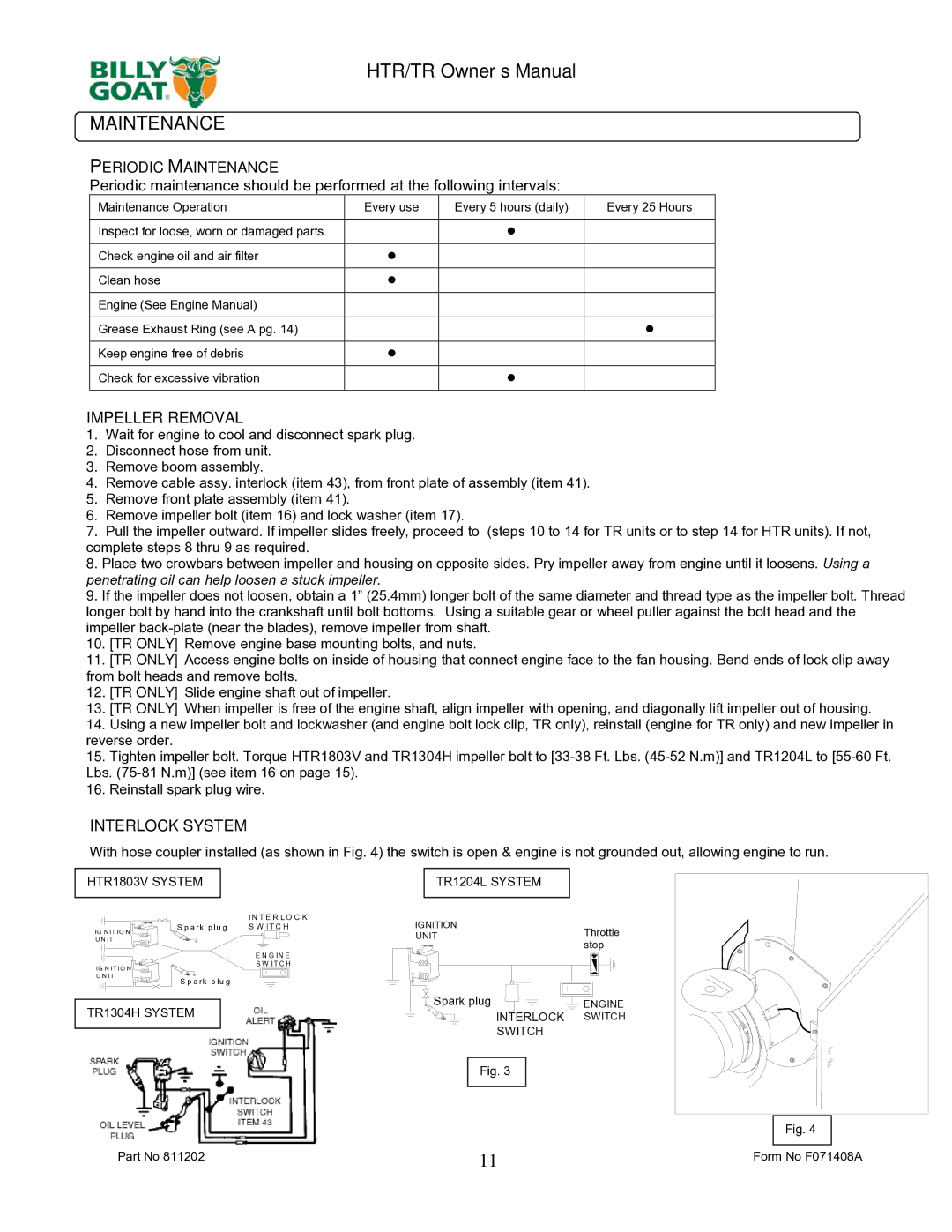

Safety is another important aspect of the TR1204L. It is built with various safety features, including a protective grill that prevents debris from escaping and ensures that users are protected during operation.

In summary, the Billy Goat TR1204L is an exemplary model of a debris loader that combines power, efficiency, and user-friendly features. Its robust engine, innovative design, and large capacity make it an essential tool for anyone looking to keep their outdoor spaces tidy and well-maintained. Whether for residential, commercial, or municipal use, the TR1204L promises to deliver reliable performance and exceptional results.