HTR/TR Owner’s Manual

VACUUMING OPERATION

EXHAUST FLAPPER: Discharging into enclosed container, position exhaust flapper

to desired opening and secure adjustment knob before starting engine. NOTE: An enclosed container must capture all debris delivered into it preventing any debris from blowing back onto unit's engine (see page 1 optional accessories).

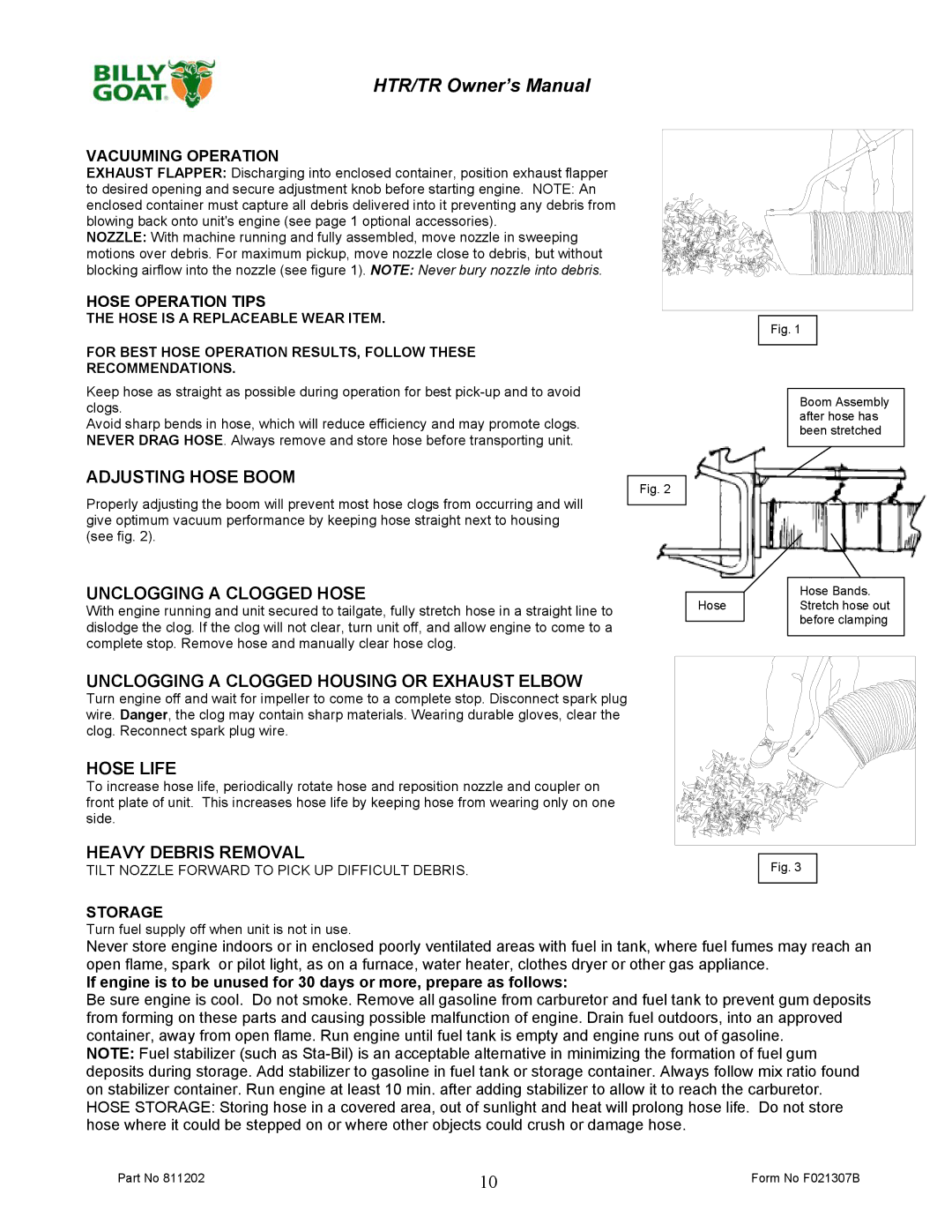

NOZZLE: With machine running and fully assembled, move nozzle in sweeping motions over debris. For maximum pickup, move nozzle close to debris, but without blocking airflow into the nozzle (see figure 1). NOTE: Never bury nozzle into debris.

HOSE OPERATION TIPS

THE HOSE IS A REPLACEABLE WEAR ITEM.

FOR BEST HOSE OPERATION RESULTS, FOLLOW THESE

RECOMMENDATIONS.

Keep hose as straight as possible during operation for best

Avoid sharp bends in hose, which will reduce efficiency and may promote clogs. NEVER DRAG HOSE. Always remove and store hose before transporting unit.

ADJUSTING HOSE BOOM

Properly adjusting the boom will prevent most hose clogs from occurring and will give optimum vacuum performance by keeping hose straight next to housing (see fig. 2).

UNCLOGGING A CLOGGED HOSE

With engine running and unit secured to tailgate, fully stretch hose in a straight line to dislodge the clog. If the clog will not clear, turn unit off, and allow engine to come to a complete stop. Remove hose and manually clear hose clog.

Fig. 2

Hose

Fig. 1

Boom Assembly after hose has been stretched

Hose Bands. Stretch hose out before clamping

UNCLOGGING A CLOGGED HOUSING OR EXHAUST ELBOW

Turn engine off and wait for impeller to come to a complete stop. Disconnect spark plug wire. Danger, the clog may contain sharp materials. Wearing durable gloves, clear the clog. Reconnect spark plug wire.

HOSE LIFE

To increase hose life, periodically rotate hose and reposition nozzle and coupler on front plate of unit. This increases hose life by keeping hose from wearing only on one side.

HEAVY DEBRIS REMOVAL

TILT NOZZLE FORWARD TO PICK UP DIFFICULT DEBRIS.

STORAGE

Turn fuel supply off when unit is not in use.

Fig. 3

Never store engine indoors or in enclosed poorly ventilated areas with fuel in tank, where fuel fumes may reach an open flame, spark or pilot light, as on a furnace, water heater, clothes dryer or other gas appliance.

If engine is to be unused for 30 days or more, prepare as follows:

Be sure engine is cool. Do not smoke. Remove all gasoline from carburetor and fuel tank to prevent gum deposits from forming on these parts and causing possible malfunction of engine. Drain fuel outdoors, into an approved container, away from open flame. Run engine until fuel tank is empty and engine runs out of gasoline.

NOTE: Fuel stabilizer (such as

Part No 811202 | 10 | Form No F021307B |