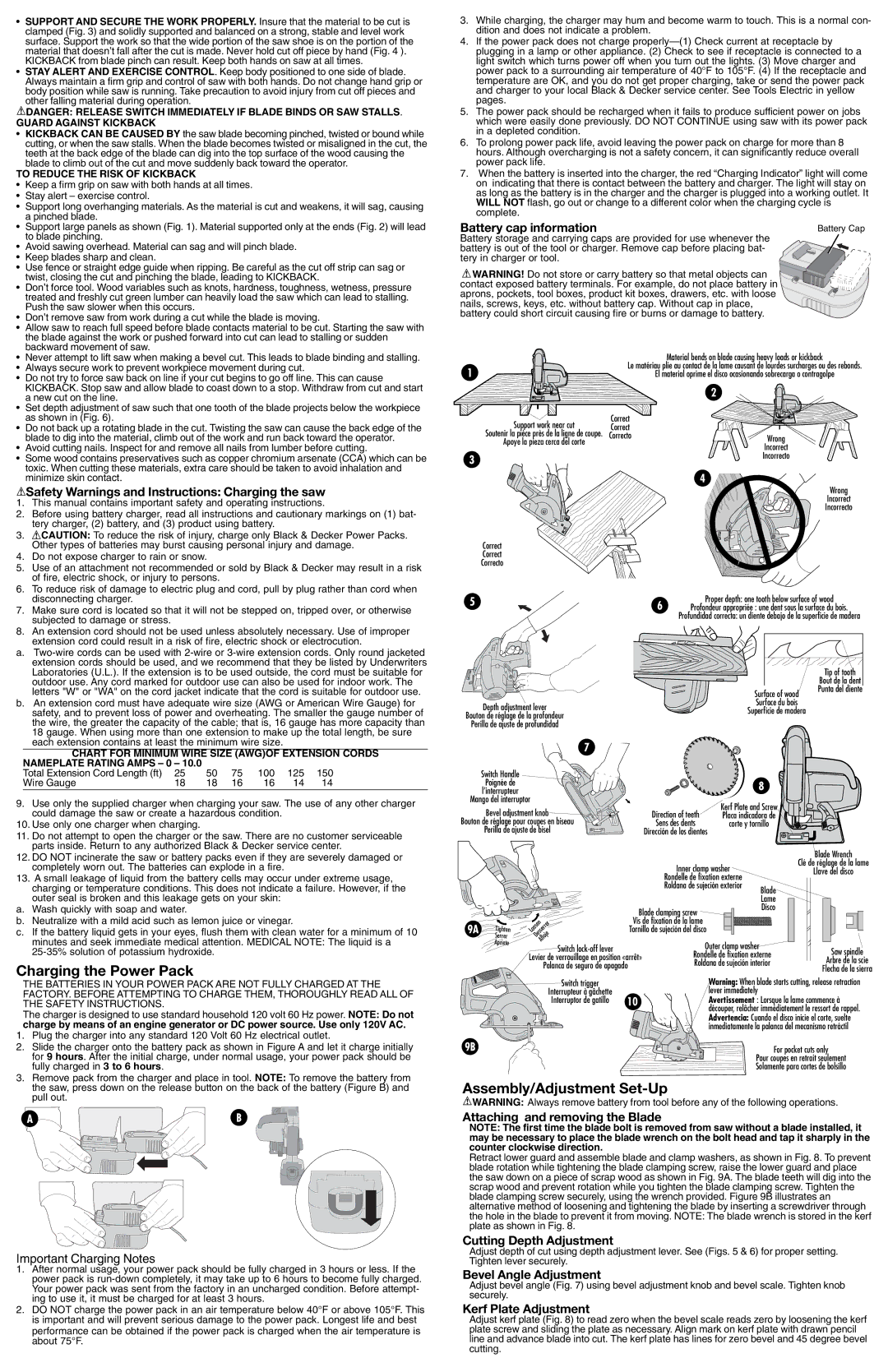

•SUPPORT AND SECURE THE WORK PROPERLY. Insure that the material to be cut is clamped (Fig. 3) and solidly supported and balanced on a strong, stable and level work surface. Support the work so that the wide portion of the saw shoe is on the portion of the material that doesn’t fall after the cut is made. Never hold cut off piece by hand (Fig. 4 ). KICKBACK from blade pinch can result. Keep both hands on saw at all times.

•STAY ALERT AND EXERCISE CONTROL. Keep body positioned to one side of blade. Always maintain a firm grip and control of saw with both hands. Do not change hand grip or body position while saw is running. Take precaution to avoid injury from cut off pieces and other falling material during operation.

![]() DANGER: RELEASE SWITCH IMMEDIATELY IF BLADE BINDS OR SAW STALLS.

DANGER: RELEASE SWITCH IMMEDIATELY IF BLADE BINDS OR SAW STALLS.

GUARD AGAINST KICKBACK

•KICKBACK CAN BE CAUSED BY the saw blade becoming pinched, twisted or bound while cutting, or when the saw stalls. When the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade can dig into the top surface of the wood causing the blade to climb out of the cut and move suddenly back toward the operator.

TO REDUCE THE RISK OF KICKBACK

• | Keep a firm grip on saw with both hands at all times. |

• | Stay alert – exercise control. |

• Support long overhanging materials. As the material is cut and weakens, it will sag, causing | |

| a pinched blade. |

• | Support large panels as shown (Fig. 1). Material supported only at the ends (Fig. 2) will lead |

| to blade pinching. |

• | Avoid sawing overhead. Material can sag and will pinch blade. |

• Keep blades sharp and clean. | |

• | Use fence or straight edge guide when ripping. Be careful as the cut off strip can sag or |

| twist, closing the cut and pinching the blade, leading to KICKBACK. |

• | Don’t force tool. Wood variables such as knots, hardness, toughness, wetness, pressure |

| treated and freshly cut green lumber can heavily load the saw which can lead to stalling. |

| Push the saw slower when this occurs. |

• | Don’t remove saw from work during a cut while the blade is moving. |

• | Allow saw to reach full speed before blade contacts material to be cut. Starting the saw with |

| the blade against the work or pushed forward into cut can lead to stalling or sudden |

| backward movement of saw. |

• | Never attempt to lift saw when making a bevel cut. This leads to blade binding and stalling. |

• Always secure work to prevent workpiece movement during cut. | |

• | Do not try to force saw back on line if your cut begins to go off line. This can cause |

| KICKBACK. Stop saw and allow blade to coast down to a stop. Withdraw from cut and start |

| a new cut on the line. |

• | Set depth adjustment of saw such that one tooth of the blade projects below the workpiece |

3.While charging, the charger may hum and become warm to touch. This is a normal con- dition and does not indicate a problem.

4.If the power pack does not charge

5.The power pack should be recharged when it fails to produce sufficient power on jobs which were easily done previously. DO NOT CONTINUE using saw with its power pack in a depleted condition.

6.To prolong power pack life, avoid leaving the power pack on charge for more than 8 hours. Although overcharging is not a safety concern, it can significantly reduce overall power pack life.

7.When the battery is inserted into the charger, the red “Charging Indicator” light will come on indicating that there is contact between the battery and charger. The light will stay on as long as the battery is in the charger and the charger is plugged into a working outlet. It WILL NOT flash, go out or change to a different color when the charging cycle is complete.

Battery cap information | Battery Cap |

Battery storage and carrying caps are provided for use whenever the battery is out of the tool or charger. Remove cap before placing bat- tery in charger or tool.

![]() WARNING! Do not store or carry battery so that metal objects can contact exposed battery terminals. For example, do not place battery in aprons, pockets, tool boxes, product kit boxes, drawers, etc. with loose nails, screws, keys, etc. without battery cap. Without cap in place, battery could short circuit causing fire or burns or damage to battery.

WARNING! Do not store or carry battery so that metal objects can contact exposed battery terminals. For example, do not place battery in aprons, pockets, tool boxes, product kit boxes, drawers, etc. with loose nails, screws, keys, etc. without battery cap. Without cap in place, battery could short circuit causing fire or burns or damage to battery.

| Material bends on blade causing heavy loads or kickback |

1 | Le matériau plie au contact de la lame causant de lourdes surcharges ou des rebonds. |

El material oprime el disco ocasionando sobrecarga o contragolpe |

2

as shown in (Fig. 6). |

• Do not back up a rotating blade in the cut. Twisting the saw can cause the back edge of the |

blade to dig into the material, climb out of the work and run back toward the operator. |

Support work near cut

Soutenir la pièce près de la ligne de coupe.

Apoye la pieza cerca del corte

Correct

Correct

Correcto

Wrong

• | Avoid cutting nails. Inspect for and remove all nails from lumber before cutting. |

• | Some wood contains preservatives such as copper chromium arsenate (CCA) which can be |

| toxic. When cutting these materials, extra care should be taken to avoid inhalation and |

| minimize skin contact. |

Safety Warnings and Instructions: Charging the saw

Safety Warnings and Instructions: Charging the saw

1. | This manual contains important safety and operating instructions. |

2. | Before using battery charger, read all instructions and cautionary markings on (1) bat- |

| tery charger, (2) battery, and (3) product using battery. |

3. | CAUTION: To reduce the risk of injury, charge only Black & Decker Power Packs. |

| Other types of batteries may burst causing personal injury and damage. |

4. | Do not expose charger to rain or snow. |

5. | Use of an attachment not recommended or sold by Black & Decker may result in a risk |

| of fire, electric shock, or injury to persons. |

6. | To reduce risk of damage to electric plug and cord, pull by plug rather than cord when |

3

Correct

Correct

Correcto

Incorrect

Incorrecto

4

Wrong

Incorrect

Incorrecto

| disconnecting charger. |

7. | Make sure cord is located so that it will not be stepped on, tripped over, or otherwise |

| subjected to damage or stress. |

8. | An extension cord should not be used unless absolutely necessary. Use of improper |

| extension cord could result in a risk of fire, electric shock or electrocution. |

5 | 6 | Proper depth: one tooth below surface of wood |

Profondeur appropriée : une dent sous la surface du bois. |

Profundidad correcta: un diente debajo de la superficie de madera

a. |

extension cords should be used, and we recommend that they be listed by Underwriters |

Laboratories (U.L.). If the extension is to be used outside, the cord must be suitable for |

outdoor use. Any cord marked for outdoor use can also be used for indoor work. The |

letters "W" or "WA" on the cord jacket indicate that the cord is suitable for outdoor use. |

b. An extension cord must have adequate wire size (AWG or American Wire Gauge) for |

Surface of wood Surface du bois

Tip of tooth

Bout de la dent Punta del diente

safety, and to prevent loss of power and overheating. The smaller the gauge number of |

the wire, the greater the capacity of the cable; that is, 16 gauge has more capacity than |

18 gauge. When using more than one extension to make up the total length, be sure |

each extension contains at least the minimum wire size. |

CHART FOR MINIMUM WIRE SIZE (AWG)OF EXTENSION CORDS

NAMEPLATE RATING AMPS – 0 – 10.0 |

|

|

|

|

| |

Total Extension Cord Length (ft) | 25 | 50 | 75 | 100 | 125 | 150 |

Wire Gauge | 18 | 18 | 16 | 16 | 14 | 14 |

9. Use only the supplied charger when charging your saw. The use of any other charger |

could damage the saw or create a hazardous condition. |

10. Use only one charger when charging. |

11. Do not attempt to open the charger or the saw. There are no customer serviceable |

parts inside. Return to any authorized Black & Decker service center. |

Depth adjustment leverSuperficie de madera Bouton de réglage de la profondeur

Perilla de ajuste de profundidad

| 7 |

| |

Switch Handle |

|

| |

Poignée de |

| 8 | |

l’interrupteur |

| ||

Mango del interruptor |

| Kerf Plate and Screw | |

Bevel adjustment knob | Direction of teeth | ||

Placa indicadora de | |||

Bouton de réglage pour coupes en biseau | Sens des dents | corte y tornillo | |

Perilla de ajuste de bisel | Dirección de los dientes |

|

12. DO NOT incinerate the saw or battery packs even if they are severely damaged or |

completely worn out. The batteries can explode in a fire. |

13. A small leakage of liquid from the battery cells may occur under extreme usage, |

charging or temperature conditions. This does not indicate a failure. However, if the |

outer seal is broken and this leakage gets on your skin: |

a.Wash quickly with soap and water.

b.Neutralize with a mild acid such as lemon juice or vinegar.

c.If the battery liquid gets in your eyes, flush them with clean water for a minimum of 10 minutes and seek immediate medical attention. MEDICAL NOTE: The liquid is a

Charging the Power Pack

THE BATTERIES IN YOUR POWER PACK ARE NOT FULLY CHARGED AT THE FACTORY. BEFORE ATTEMPTING TO CHARGE THEM, THOROUGHLY READ ALL OF THE SAFETY INSTRUCTIONS.

The charger is designed to use standard household 120 volt 60 Hz power. NOTE: Do not charge by means of an engine generator or DC power source. Use only 120V AC.

1. | Plug the charger into any standard 120 Volt 60 Hz electrical outlet. |

2. | Slide the charger onto the battery pack as shown in Figure A and let it charge initially |

| for 9 hours. After the initial charge, under normal usage, your power pack should be |

| fully charged in 3 to 6 hours. |

3. | Remove pack from the charger and place in tool. NOTE: To remove the battery from |

9A

9B

Tighten

Serrer

Apriete

|

|

|

|

| Blade Wrench | |

|

|

| Inner clamp washer |

| Clé de réglage de la lame | |

|

|

|

| Llave del disco | ||

|

|

| Rondelle de fixation externe |

|

| |

|

|

| Roldana de sujeción exterior | Blade |

| |

|

|

|

|

| ||

|

|

|

| Lame |

| |

|

| Blade clamping screw | Disco |

| ||

|

|

|

| |||

Loosen | Vis de fixation de la lame |

|

| |||

Tornillo de sujeción del disco |

|

| ||||

Desserrer |

|

|

|

|

| |

Afloje |

|

| Outer clamp washer |

|

| |

Switch |

|

|

| Saw spindle | ||

|

| Rondelle de fixation externe | ||||

Levier de verrouillage en position «arrêt» | ||||||

Roldana de sujeción interior | Arbre de la scie | |||||

Palanca de seguro de apagado |

| |||||

|

|

| Flecha de la sierra | |||

|

|

|

|

| ||

Switch trigger |

|

| Warning: When blade starts cutting, release retraction | |||

Interrupteur à gâchette | 10 |

| lever immediately |

|

| |

Interruptor de gatillo |

| Avertissement : Lorsque la lame commence à | ||||

|

|

| découper, relâcher immédiatement le ressort de rappel. | |||

Advertencia: Cuando el disco inicie el corte, suelte inmediatamente la palanca del mecanismo retráctil

For pocket cuts only

Pour coupes en retrait seulement

Solamente para cortes de bolsillo

the saw, press down on the release button on the back of the battery (Figure B) and |

pull out. |

AB

Important Charging Notes

1.After normal usage, your power pack should be fully charged in 3 hours or less. If the power pack is

2.DO NOT charge the power pack in an air temperature below 40°F or above 105°F. This is important and will prevent serious damage to the power pack. Longest life and best

performance can be obtained if the power pack is charged when the air temperature is about 75°F.

Assembly/Adjustment Set-Up

![]() WARNING: Always remove battery from tool before any of the following operations.

WARNING: Always remove battery from tool before any of the following operations.

Attaching and removing the Blade

NOTE: The first time the blade bolt is removed from saw without a blade installed, it may be necessary to place the blade wrench on the bolt head and tap it sharply in the counter clockwise direction.

Retract lower guard and assemble blade and clamp washers, as shown in Fig. 8. To prevent blade rotation while tightening the blade clamping screw, raise the lower guard and place the saw down on a piece of scrap wood as shown in Fig. 9A. The blade teeth will dig into the scrap wood and prevent rotation while you tighten the blade clamping screw. Tighten the blade clamping screw securely, using the wrench provided. Figure 9B illustrates an alternative method of loosening and tightening the blade by inserting a screwdriver through the hole in the blade to prevent it from moving. NOTE: The blade wrench is stored in the kerf plate as shown in Fig. 8.

Cutting Depth Adjustment

Adjust depth of cut using depth adjustment lever. See (Figs. 5 & 6) for proper setting. Tighten lever securely.

Bevel Angle Adjustment

Adjust bevel angle (Fig. 7) using bevel adjustment knob and bevel scale. Tighten knob securely.

Kerf Plate Adjustment

Adjust kerf plate (Fig. 8) to read zero when the bevel scale reads zero by loosening the kerf plate screw and sliding the plate as necessary. Align mark on kerf plate with drawn pencil line and advance blade into cut. The kerf plate has lines for zero bevel and 45 degree bevel cutting.