Cleaning and Disposal

•All surfaces in the work area should be vacuumed and thoroughly cleaned daily for the duration of the sanding project. Vacuum filter bags should be changed frequently.

•Plastic drop cloths should be gathered up and disposed of along with any dust chips or other removal debris. They should be placed in sealed refuse receptacles and disposed of through regular trash pick-up procedures. During clean up, children and pregnant women should be kept away from the immediate work area.

•All toys, washable furniture and utensils used by children should be washed thoroughly before being used again.

Motor

Be sure your power supply agrees with nameplate marking. 120 Volts AC only means your tool will operate on standard 60 Hz household power. Do not operate AC tools on DC. A rating of 120 volts AC/DC means that you tool will operate on standard 60 Hz AC or DC power. This information is printed on the nameplate. Lower voltage will cause loss of power and can result in over-heating. All Black & Decker tools are factory-tested; if this tool does not operate, check the power supply.

BATTERY CAP INFORMATION

Battery storage and carrying caps are provided for use whenever the battery is out of the tool or charger. Remove cap before placing battery in charger or tool.

Battery Cap

WARNING: Do not store or carry battery so that metal objects can contact exposed battery terminals. For example, do not place battery in aprons, pockets, tool boxes, product kit boxes, drawers, etc. with loose nails, screws, keys, etc. without battery cap. Transporting batteries can possibly cause fires if the battery terminals inadvertently come in contact with conductive materials such as keys, coins, hand tools and the like. The US Department of Transportation Hazardous Material Regulations (HMR) actually prohibit transporting batteries in commerce or on airplanes (i.e. packed in suitcases and carryon luggage) UNLESS they are properly protected from short circuits. So when transporting individual batteries, make sure that the battery terminals are protected and well insulated from materials that could contact them and cause a short circuit.

WARNING: Do not store or carry battery so that metal objects can contact exposed battery terminals. For example, do not place battery in aprons, pockets, tool boxes, product kit boxes, drawers, etc. with loose nails, screws, keys, etc. without battery cap. Transporting batteries can possibly cause fires if the battery terminals inadvertently come in contact with conductive materials such as keys, coins, hand tools and the like. The US Department of Transportation Hazardous Material Regulations (HMR) actually prohibit transporting batteries in commerce or on airplanes (i.e. packed in suitcases and carryon luggage) UNLESS they are properly protected from short circuits. So when transporting individual batteries, make sure that the battery terminals are protected and well insulated from materials that could contact them and cause a short circuit.

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

•SAVE THESE INSTRUCTIONS.

•Before using charger, read and understand all instructions and cautionary markings on

(1) charger, (2) battery pack, and (3) product using battery pack.

DANGER: 120 volts present at charging terminals. Do not probe with conductive objects. Danger of electric shock or electrocution.

DANGER: 120 volts present at charging terminals. Do not probe with conductive objects. Danger of electric shock or electrocution.

DANGER: If battery pack case is cracked or damaged, do not insert into charger. Danger of electric shock or electrocution.

DANGER: If battery pack case is cracked or damaged, do not insert into charger. Danger of electric shock or electrocution.

DANGER: Never attempt to open the battery pack for any reason. If the plastic housing of the battery pack breaks or cracks, return to a service center for recycling.

DANGER: Never attempt to open the battery pack for any reason. If the plastic housing of the battery pack breaks or cracks, return to a service center for recycling.

WARNING: Don’t allow any liquid to get inside charger. Electric shock may result.

WARNING: Don’t allow any liquid to get inside charger. Electric shock may result.  CAUTION: To reduce risk of injury, charge only Black & Decker rechargeable batteries. Other types of batteries may burst, causing personal injury and damage.

CAUTION: To reduce risk of injury, charge only Black & Decker rechargeable batteries. Other types of batteries may burst, causing personal injury and damage.

•To facilitate the cooling of the battery pack after use, avoid placing the charger or battery pack in a warm environment such as in a metal shed, or an uninsulated trailer.

•Do not expose charger to rain or snow.

•Use of an attachment not recommended or sold by Black & Decker may result in risk of fire, electric shock, or injury to persons.

•This charger is not intended for any uses other than charging Black & Decker rechargeable batteries. Any other uses may result in risk of fire, electric shock or electrocution.

•To reduce risk of damage to electric plug and cord, pull by plug rather than cord when disconnecting charger.

•Make sure cord is located so that it will not be stepped on, tripped over, or otherwise subjected to damage or stress.

•An extension cord should not be used unless absolutely necessary. Use of improper extension cord could result in risk of fire, electric shock, or electrocution. If an extension cord must be used, make sure:

•That the pins on plug of extension cord are the same number, size and shape of those of plug on charger.

•That extension cord is properly wired and in good electrical condition and the wire size is large enough for AC ampere rating of charger as specified below.

An extension cord must have adequate wire size (AWG or American Wire Gauge) for safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that is, 16 gauge has more capacity than 18 gauge. When using more than one extension to make up the total length, be sure each individual extension contains at least the minimum wire size.

RECOMMENDED MINIMUM AWG SIZE FOR EXTENSION CORDS

TOTAL EXTENSION CORD LENGTH (FEET)

25 | 50 | 75 | 100 | 125 | 150 | 175 |

WIRE GAUGE | | | | | | |

18 | 18 | 16 | 16 | 14 | 14 | 12 |

•The charger is ventilated through slots in the housing. Do not place any object on top of charger or place the charger on a soft surface that might block the ventilation slots and result in excessive internal heat. Place the charger in a position away from any heat source.

•Do not operate charger with damaged cord or plug — have them replaced immediately.

•Do not operate charger if it has received a sharp blow, been dropped, or otherwise damaged in any way; take it to an authorized service center.

•Do not disassemble charger; take it to an authorized service center when service or repair is required. Incorrect reassembly may result in risk of electric shock, electrocution or fire.

•The charger is designed to operate on standard120 VAC, 60Hz household electrical power. Do not attempt to use it on any other voltage.

•To reduce risk of electric shock, unplug charger from outlet before attempting any cleaning. Removing the battery pack will not reduce this risk.

•NEVER attempt to connect 2 chargers together.

•DO NOT store or use the tool and battery pack in locations where the temperature may reach or exceed 105°F (such as outside sheds or metal buildings in summer).

•A small leakage of liquid from the battery cells may occur under extreme usage, charging or temperature conditions. This does not indicate a failure. However, if the outer seal is broken and this leakage gets on your skin:

a.Wash quickly with soap and water.

b.Neutralize with a mild acid such as lemon juice or vinegar.

c.If the battery liquid gets in your eyes, flush them with clean water for a minimum of 10 minutes and seek immediate medical attention. MEDICAL NOTE: The liquid is a 25-35% solution of potassium hydroxide.

SAVE THESE INSTRUCTIONS

INTRODUCTION

READ AND UNDERSTAND ALL OF THE INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING TO CHARGE THE BATTERY PACK FOR YOUR TOOL.

Your charger is designed to use standard 120 volt AC, 60 Hz power. Do not use DC or any other voltage. Charge time is 3 to 6 hours depending on battery pack type and condition.

CHARGING PROCEDURE

1.Plug the charger into an appropriate outlet.

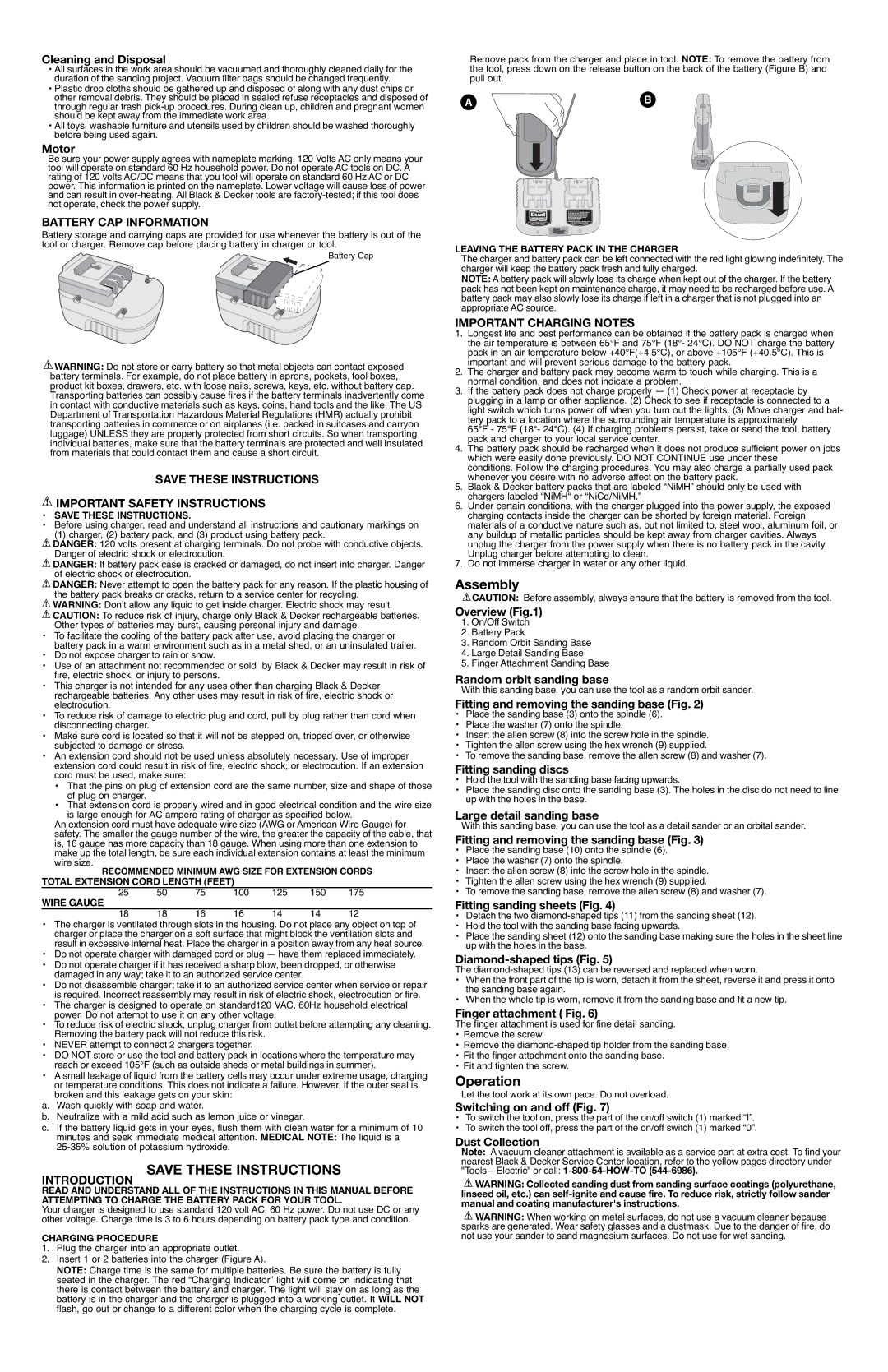

2.Insert 1 or 2 batteries into the charger (Figure A).

NOTE: Charge time is the same for multiple batteries. Be sure the battery is fully seated in the charger. The red “Charging Indicator” light will come on indicating that there is contact between the battery and charger. The light will stay on as long as the battery is in the charger and the charger is plugged into a working outlet. It WILL NOT flash, go out or change to a different color when the charging cycle is complete.

Remove pack from the charger and place in tool. NOTE: To remove the battery from the tool, press down on the release button on the back of the battery (Figure B) and pull out.

A B

B

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with the red light glowing indefinitely. The charger will keep the battery pack fresh and fully charged.

NOTE: A battery pack will slowly lose its charge when kept out of the charger. If the battery pack has not been kept on maintenance charge, it may need to be recharged before use. A battery pack may also slowly lose its charge if left in a charger that is not plugged into an appropriate AC source.

IMPORTANT CHARGING NOTES

1.Longest life and best performance can be obtained if the battery pack is charged when the air temperature is between 65°F and 75°F (18°- 24°C). DO NOT charge the battery pack in an air temperature below +40°F(+4.5°C), or above +105°F (+40.5°C). This is important and will prevent serious damage to the battery pack.

2.The charger and battery pack may become warm to touch while charging. This is a normal condition, and does not indicate a problem.

3.If the battery pack does not charge properly — (1) Check power at receptacle by plugging in a lamp or other appliance. (2) Check to see if receptacle is connected to a light switch which turns power off when you turn out the lights. (3) Move charger and bat- tery pack to a location where the surrounding air temperature is approximately

65°F - 75°F (18°- 24°C). (4) If charging problems persist, take or send the tool, battery pack and charger to your local service center.

4.The battery pack should be recharged when it does not produce sufficient power on jobs which were easily done previously. DO NOT CONTINUE use under these conditions. Follow the charging procedures. You may also charge a partially used pack whenever you desire with no adverse affect on the battery pack.

5.Black & Decker battery packs that are labeled “NiMH” should only be used with chargers labeled “NiMH“ or “NiCd/NiMH.”

6.Under certain conditions, with the charger plugged into the power supply, the exposed charging contacts inside the charger can be shorted by foreign material. Foreign materials of a conductive nature such as, but not limited to, steel wool, aluminum foil, or any buildup of metallic particles should be kept away from charger cavities. Always unplug the charger from the power supply when there is no battery pack in the cavity. Unplug charger before attempting to clean.

7.Do not immerse charger in water or any other liquid.

Assembly

CAUTION: Before assembly, always ensure that the battery is removed from the tool.

CAUTION: Before assembly, always ensure that the battery is removed from the tool.

Overview (Fig.1)

1.On/Off Switch

2.Battery Pack

3.Random Orbit Sanding Base

4.Large Detail Sanding Base

5.Finger Attachment Sanding Base

Random orbit sanding base

With this sanding base, you can use the tool as a random orbit sander.

Fitting and removing the sanding base (Fig. 2)

•Place the sanding base (3) onto the spindle (6).

•Place the washer (7) onto the spindle.

•Insert the allen screw (8) into the screw hole in the spindle.

•Tighten the allen screw using the hex wrench (9) supplied.

•To remove the sanding base, remove the allen screw (8) and washer (7).

Fitting sanding discs

•Hold the tool with the sanding base facing upwards.

•Place the sanding disc onto the sanding base (3). The holes in the disc do not need to line up with the holes in the base.

Large detail sanding base

With this sanding base, you can use the tool as a detail sander or an orbital sander.

Fitting and removing the sanding base (Fig. 3)

•Place the sanding base (10) onto the spindle (6).

•Place the washer (7) onto the spindle.

•Insert the allen screw (8) into the screw hole in the spindle.

•Tighten the allen screw using the hex wrench (9) supplied.

•To remove the sanding base, remove the allen screw (8) and washer (7).

Fitting sanding sheets (Fig. 4)

•Detach the two diamond-shaped tips (11) from the sanding sheet (12).

•Hold the tool with the sanding base facing upwards.

•Place the sanding sheet (12) onto the sanding base making sure the holes in the sheet line up with the holes in the base.

Diamond-shaped tips (Fig. 5)

The diamond-shaped tips (13) can be reversed and replaced when worn.

•When the front part of the tip is worn, detach it from the sheet, reverse it and press it onto the sanding base again.

•When the whole tip is worn, remove it from the sanding base and fit a new tip.

Finger attachment ( Fig. 6)

The finger attachment is used for fine detail sanding.

•Remove the screw.

•Remove the diamond-shaped tip holder from the sanding base.

•Fit the finger attachment onto the sanding base.

•Fit and tighten the screw.

Operation

Let the tool work at its own pace. Do not overload.

Switching on and off (Fig. 7)

•To switch the tool on, press the part of the on/off switch (1) marked “I”.

•To switch the tool off, press the part of the on/off switch (1) marked “0”.

Dust Collection

Note: A vacuum cleaner attachment is available as a service part at extra cost. To find your nearest Black & Decker Service Center location, refer to the yellow pages directory under "Tools—Electric" or call: 1-800-54-HOW-TO(544-6986).

WARNING: Collected sanding dust from sanding surface coatings (polyurethane, linseed oil, etc.) can self-ignite and cause fire. To reduce risk, strictly follow sander manual and coating manufacturer's instructions.

WARNING: Collected sanding dust from sanding surface coatings (polyurethane, linseed oil, etc.) can self-ignite and cause fire. To reduce risk, strictly follow sander manual and coating manufacturer's instructions.

WARNING: When working on metal surfaces, do not use a vacuum cleaner because sparks are generated. Wear safety glasses and a dustmask. Due to the danger of fire, do not use your sander to sand magnesium surfaces. Do not use for wet sanding.

WARNING: When working on metal surfaces, do not use a vacuum cleaner because sparks are generated. Wear safety glasses and a dustmask. Due to the danger of fire, do not use your sander to sand magnesium surfaces. Do not use for wet sanding.