4-1/ 2” ANGLE GRINDER

INSTRUCTION MANUAL

Catalog # G950

Catalog # G950

B E F O R E R E T U R N I N G T H I S P R O D U C T

F O R A N Y R E A S O N P L E A S E C A L L

1 - 8 0 0 - 5 4 4 - 6 9 8 6

IF YOU SHOULD HAVE A QUESTION OR EXPERIENCE A PROBLEM WITH YOUR BLACK & DECKER PRODUCT,

CALL 1 - 800 - 544 - 6986

BEFORE YOU CALL, HAVE THE FOLLOWING INFORMATION AVAILABLE, CATALOG No.,

TYPE No., AND DATE CODE (e.g. 0130M). IN MOST CASES, A BLACK & DECKER

REPRESENTATIVE CAN RESOLVE YOUR PROBLEM OVER THE PHONE. IF YOU HAVE A

SUGGESTION OR COMMENT, GIVE US A CALL. YOUR FEEDBACK IS VITAL

TO BLACK & DECKER.

INFORMATION YOU SHOULD KNOW

•Wait until grinding wheel reaches full speed before applying work.

•Hold grinder at proper angle, as shown in Figure 11 and 12.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y

PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

CAT. NO. G950 FORM NO. 587915-00 Copyright © 2004 Black & Decker (JUNE-04) Printed in China

General Safety Rules

WARNING! Read and understand all instructions. Failure to follow all instructions listed below may result in electric shock, fire and/or serious personal injury.

WARNING! Read and understand all instructions. Failure to follow all instructions listed below may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

•Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

•Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or fumes.

•Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

•Double insulated tools are equipped with a polarized plug (one blade is wider than the other.) This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install a polarized outlet. Do not change the plug in any way. Double insulation  eliminates the need for the three wire grounded power cord and grounded power supply system.

eliminates the need for the three wire grounded power cord and grounded power supply system.

•Avoid body contact with grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is grounded.

•Don’t expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

•Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

•When operating a power tool outside, use an outdoor extension cord marked "W-A" or "W." These cords are rated for outdoor use and reduce the risk of electric shock.

Personal Safety

•Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury,

•Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair and clothing away from moving parts. Loose clothing, jewelry, or long hair can be caught in moving parts.

•Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with your finger on the switch or plugging in tools that have the switch on invites accidents.

•Remove adjusting keys or wrenches before turning the tool on. A wrench or key that is left attached to a rotating part of the tool may result in personal injury.

•Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enables better control of the tool in unexpected situations.

•Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat, or hearing protection must be used for appropriate conditions.

Tool Use and Care

•Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable and may lead to a loss of control.

•Do not force tool. Use the correct tool for your application. The correct tool will do the job better and safer at the rate for which it is designed.

•Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with the switch is dangerous and must be repaired.

•Disconnect the plug from the power source before making any adjustments, changing accessories, or storing the tool. Such preventative safety measures reduce the risk of starting the tool accidentally.

•Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

•Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools, with sharp cutting edges are less likely to bind and are easier to control.

•Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the tools operation. If damaged, have the tool serviced before using. Many accidents are caused by poorly maintained tools.

•Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on another tool.

Service

•Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel could result in a risk of injury.

•When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance section of this manual. Use of unauthorized parts or failure to follow Maintenance Instructions may create a risk of electric shock or injury.

SAVE THESE INSTRUCTIONS

Specific Safety Rules

•Always use proper guard with grinding wheel. A guard protects operator from broken wheel fragments. Always position the guard so that as much of the exposed disc as possible is pointing away from you.

•Accessories must be rated for at least the speed recommended on the tool warning label. Wheels and other accessories running over rated speed can fly apart and cause injury.

•Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will make exposed metal parts of the tool "live" and shock the operator.

Additional Safety Rules

•ALWAYS WEAR EYE PROTECTION.

•WEAR EAR PROTECTION. NOISE LEVEL MAY BE AMPLIFIED WHEN GRINDING IN ENCLOSED SPACES.

•KEEP GUARDS IN PLACE.

•Use only accessories having a maximum operating speed at least as high as the speed specified in the warning on the tool’s label.

•Before using, inspect recommended accessory for cracks or flaws. If such a crack or flaw is evident, discard the accessory. The accessory should also be inspected whenever you think the tool may have been dropped.

•When starting the tool (with a new or replacement wheel or brush installed) hold the tool in a well protected area and let it run for one minute. If the wheel or brush has an undetected crack or flaw, it should burst or separate in less than one minute. Never start the tool with a person in line with the accessory. This includes the operator.

•In operation, avoid bouncing the wheel or giving it rough treatment. If this occurs, stop the tool and inspect the wheel.

•ALWAYS USE GUARDS with grinding wheels and wire brushes. Always position the guard so that as much of the exposed wheel or wire brush as possible is pointing away from you.

•Clean your tool out periodically.

•Do not use Type 1 flat cut-off abrasive or diamond wheels without proper guard. (Guard not included with unit.)

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•lead from lead-based paints,

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

•Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities. Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disperse dust, which may cause serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

WARNING: Use of this tool can generate and/or disperse dust, which may cause serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

CAUTION: Wear appropriate hearing protection during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

CAUTION: Wear appropriate hearing protection during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

•Do not operate this tool for long periods of time. Vibration caused by the operating action of this tool may cause permanent injury to fingers, hands, and arms. Use gloves to provide extra cushion, take frequent rest periods, and limit daily time of use.

The label on your tool may include the following symbols. | |

V | volts | A | amperes |

Hz | hertz | W | watts |

min | minutes | no | alternating current |

| | | direct current | no load speed |

| | ...................... |

| .......................... | Class II Construction | | | ........................ | earthing terminal |

| | | | | |

| ........................ | safety alert symbol | | | | |

SPM | strokes per minute | | | | |

.../min | revolutions or | | | | |

| | | reciprocations per minute | | | | |

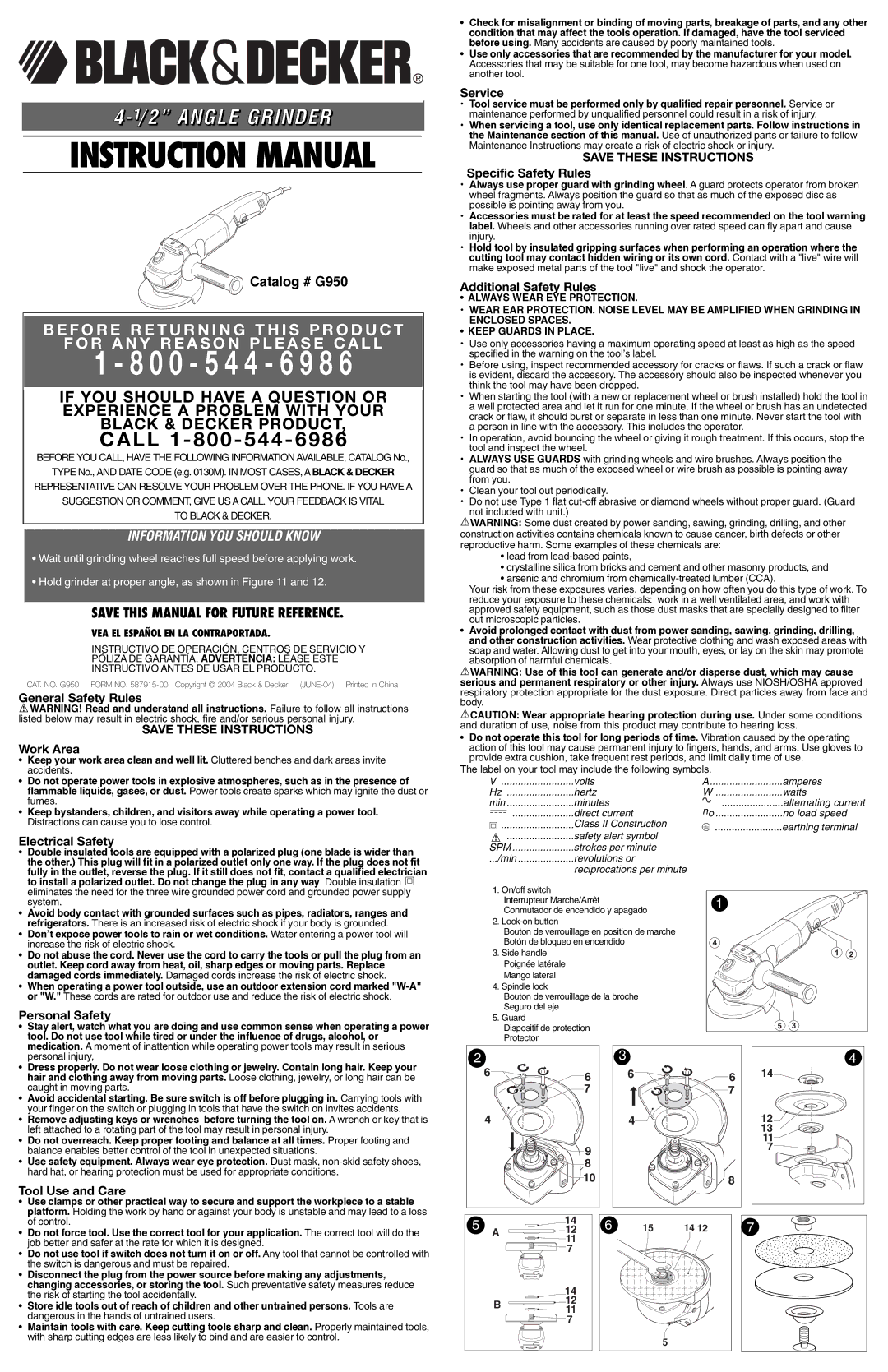

| 1. On/off switch | | | | | |

| | Interrupteur Marche/Arrêt | | | | 1 | |

| | Conmutador de encendido y apagado | | |

| | | | |

| 2. Lock-on button | | | | | |

| | Bouton de verrouillage en position de marche | | | |

| | Botón de bloqueo en encendido | | | | |

| 3. Side handle | | | | | |

| | Poignée latérale | | | | | |

| | Mango lateral | | | | | |

| 4. Spindle lock | | | | | |

| | Bouton de verrouillage de la broche | | | |

| | Seguro del eje | | | | | |

| 5. Guard | | | | | |

| | Dispositif de protection | | | | | |

| | Protector | | | | | |

2 | | | 3 | | | | 4 |

6 | | 6 | | 6 | | 6 | 14 |

| | 7 | | | | 7 | |

4 | | | | 4 | | | 12 |

| | | | | | | 13 |

| | | | | | | 11 |

| | 9 | | | | | 7 |

| | | | | | |

| | 8 | | | | | |

| | 10 | | | | 8 | |

5 | | 14 | 6 | 15 | 14 12 | | 7 |

A | 12 | |

| | 11 | | | | | |

| | 7 | | | | | |

14

B  12

12

11

11  7

7

5