90565379 LDX116

3.If the battery pack does not charge properly:

a.Check current at receptacle by plugging in a lamp or other appliance

b.Check to see if receptacle is connected to a light switch which turns power off when you turn out the lights.

c.Move charger and battery pack to a location where the surrounding air temperature is approximately 65°F - 75°F (18°- 24°C).

d.If charging problems persist, take the tool, battery pack and charger to your local service center.

4.The battery pack should be recharged when it fails to produce sufficient power on jobs which were easily done previously. DO NOT CONTINUE to use under these conditions. Follow the charging procedure. You may also charge a partially used pack whenever you desire with no adverse affect on the battery pack.

5.Foreign materials of a conductive nature such as, but not limited to, steel wool, aluminum foil, or any buildup of metallic particles should be kept away from charger cavities. Always unplug the charger from the power supply when there is no battery pack in the cavity. Unplug charger before attempting to clean.

6.Do not freeze or immerse charger in water or any other liquid.

![]() WARNING: Shock hazard. Do not allow any liquid to get inside charger. Never attempt to open the battery pack for any reason. If the plastic housing of the battery pack breaks or cracks, return to a service center for recycling.

WARNING: Shock hazard. Do not allow any liquid to get inside charger. Never attempt to open the battery pack for any reason. If the plastic housing of the battery pack breaks or cracks, return to a service center for recycling.

SAFETY WARNINGS AND INSTRUCTIONS: DRILLS

1.Hold drill firmly with one hand on the grip and the other hand on the bottom of the battery pack.

2.When attaching accessories in the drill chuck, hand tighten the keyless chuck firmly. ![]() WARNING: Drill may stall (if overloaded or improperly used) causing a twist. Always

WARNING: Drill may stall (if overloaded or improperly used) causing a twist. Always

expect the stall. Grip the drill firmly with both hands to control the twisting action and prevent loss of control which could cause personal injury. If a stall does occur, release the trigger immediately and determine the reason for the stall before

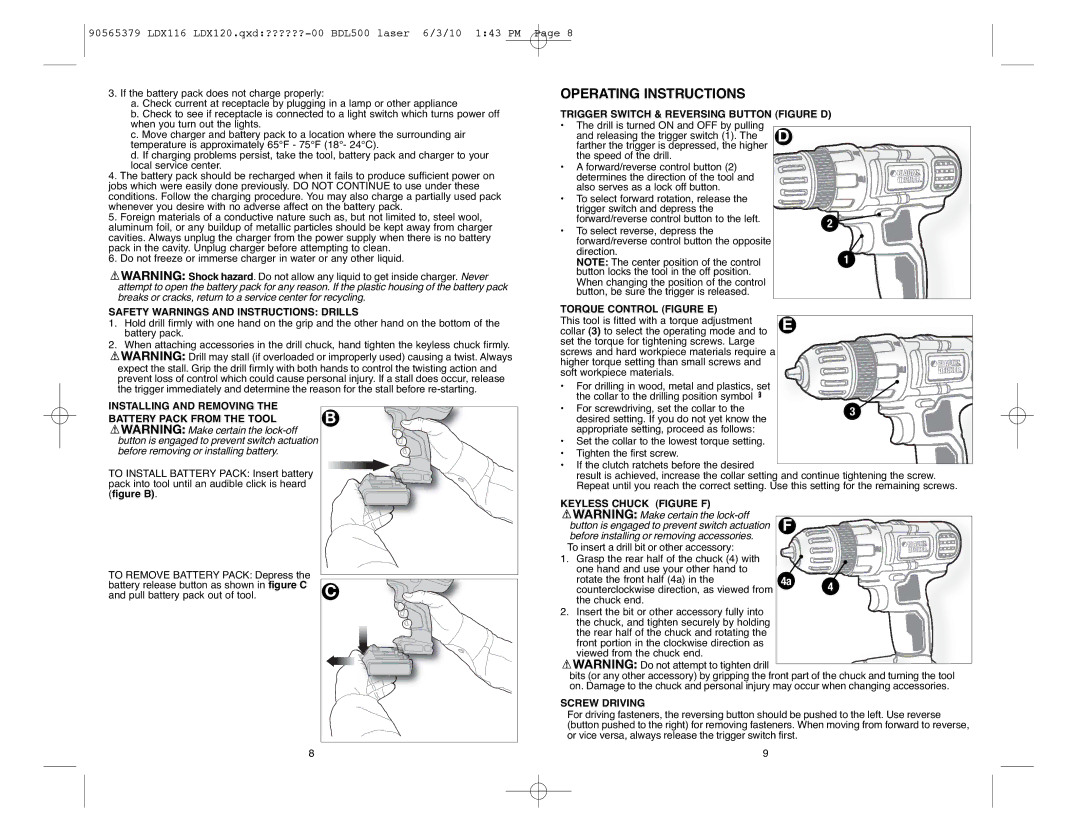

INSTALLING AND REMOVING THE | B |

BATTERY PACK FROM THE TOOL |

![]() WARNING: Make certain the

WARNING: Make certain the

TO INSTALL BATTERY PACK: Insert battery pack into tool until an audible click is heard (figure B).

TO REMOVE BATTERY PACK: Depress the |

|

battery release button as shown in figure C | C |

and pull battery pack out of tool. |

8

OPERATING INSTRUCTIONS

TRIGGER SWITCH & REVERSING BUTTON (FIGURE D)

•The drill is turned ON and OFF by pulling

and releasing the trigger switch (1). The | D |

| |

farther the trigger is depressed, the higher |

|

| |

the speed of the drill. |

|

| |

• A forward/reverse control button (2) |

|

| |

determines the direction of the tool and |

|

| |

also serves as a lock off button. |

|

| |

• To select forward rotation, release the |

|

| |

trigger switch and depress the |

|

| |

forward/reverse control button to the left. | 2 |

| |

• To select reverse, depress the |

|

| |

forward/reverse control button the opposite |

|

| |

direction. | 1 |

| |

NOTE: The center position of the control |

| ||

button locks the tool in the off position. |

|

| |

When changing the position of the control |

|

| |

button, be sure the trigger is released. |

|

|

|

TORQUE CONTROL (FIGURE E) |

|

| |

This tool is fitted with a torque adjustment | E |

| |

collar (3) to select the operating mode and to |

| ||

set the torque for tightening screws. Large |

|

| |

screws and hard workpiece materials require a |

|

| |

higher torque setting than small screws and |

|

| |

soft workpiece materials. |

|

| |

• For drilling in wood, metal and plastics, set |

|

| |

the collar to the drilling position symbol |

|

| |

• For screwdriving, set the collar to the | 3 |

| |

desired setting. If you do not yet know the |

|

| |

appropriate setting, proceed as follows: |

|

| |

•Set the collar to the lowest torque setting.

•Tighten the first screw.

•If the clutch ratchets before the desired

result is achieved, increase the collar setting and continue tightening the screw. Repeat until you reach the correct setting. Use this setting for the remaining screws.

KEYLESS CHUCK (FIGURE F)

![]() WARNING: Make certain the

WARNING: Make certain the

button is engaged to prevent switch actuation F before installing or removing accessories.

To insert a drill bit or other accessory:

1. Grasp the rear half of the chuck (4) with |

|

|

one hand and use your other hand to | 4a |

|

rotate the front half (4a) in the | 4 | |

counterclockwise direction, as viewed from |

| |

the chuck end. |

|

|

2.Insert the bit or other accessory fully into the chuck, and tighten securely by holding the rear half of the chuck and rotating the front portion in the clockwise direction as

viewed from the chuck end. ![]() WARNING: Do not attempt to tighten drill

WARNING: Do not attempt to tighten drill

bits (or any other accessory) by gripping the front part of the chuck and turning the tool on. Damage to the chuck and personal injury may occur when changing accessories.

SCREW DRIVING

For driving fasteners, the reversing button should be pushed to the left. Use reverse (button pushed to the right) for removing fasteners. When moving from forward to reverse, or vice versa, always release the trigger switch first.

9