90550750 VEC049DCB GOOD ONE.qxp 6/5/09 1:46 PM Page 8

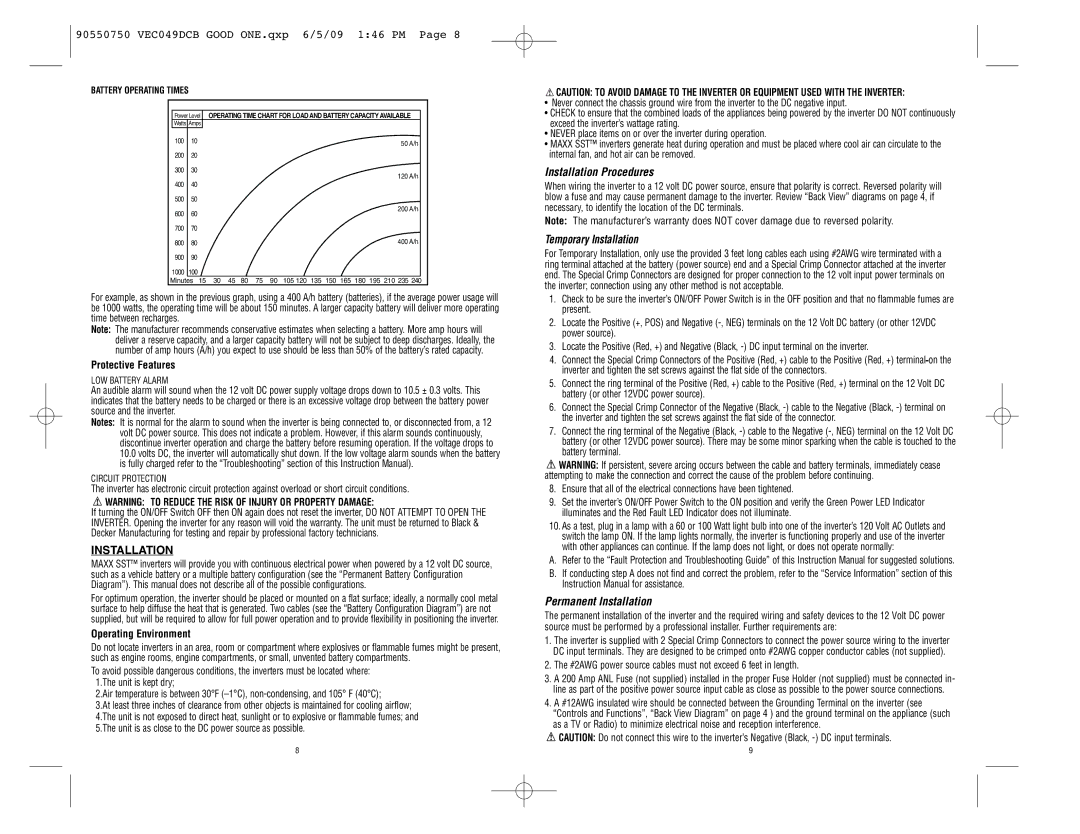

BATTERY OPERATING TIMES

Power Level | OPERATING TIME CHART FOR LOAD AND BATTERY CAPACITY AVAILABLE |

Watts Amps | |

100 | 10 | 50 A/h |

| |

20020

30030

| | | | | | | | | 120 A/h |

400 | 40 | | | | | | | | | |

500 | 50 | | | | | | | | | |

600 | 60 | | | | | | | | 200 A/h |

| | | | | | | | |

700 | 70 | | | | | | | | | |

800 | 80 | | | | | | | | 400 A/h |

900 | 90 | | | | | | | | | |

1000 | 100 | | | | | | | | | |

Minutes | 15 | 30 | 45 | 80 | 75 | 90 | 105 120 135 150 165 180 195 | 210 235 240 | |

For example, as shown in the previous graph, using a 400 A/h battery (batteries), if the average power usage will be 1000 watts, the operating time will be about 150 minutes. A larger capacity battery will deliver more operating time between recharges.

Note: The manufacturer recommends conservative estimates when selecting a battery. More amp hours will deliver a reserve capacity, and a larger capacity battery will not be subject to deep discharges. Ideally, the number of amp hours (A/h) you expect to use should be less than 50% of the battery’s rated capacity.

Protective Features

LOW BATTERY ALARM

An audible alarm will sound when the 12 volt DC power supply voltage drops down to 10.5 ± 0.3 volts. This indicates that the battery needs to be charged or there is an excessive voltage drop between the battery power source and the inverter.

Notes: It is normal for the alarm to sound when the inverter is being connected to, or disconnected from, a 12 volt DC power source. This does not indicate a problem. However, if this alarm sounds continuously, discontinue inverter operation and charge the battery before resuming operation. If the voltage drops to

10.0volts DC, the inverter will automatically shut down. If the low voltage alarm sounds when the battery is fully charged refer to the “Troubleshooting” section of this Instruction Manual).

CIRCUIT PROTECTION

The inverter has electronic circuit protection against overload or short circuit conditions.

WARNING: TO REDUCE THE RISK OF INJURY OR PROPERTY DAMAGE:

WARNING: TO REDUCE THE RISK OF INJURY OR PROPERTY DAMAGE:

If turning the ON/OFF Switch OFF then ON again does not reset the inverter, DO NOT ATTEMPT TO OPEN THE INVERTER. Opening the inverter for any reason will void the warranty. The unit must be returned to Black & Decker Manufacturing for testing and repair by professional factory technicians.

INSTALLATION

MAXX SST™ inverters will provide you with continuous electrical power when powered by a 12 volt DC source, such as a vehicle battery or a multiple battery configuration (see the “Permanent Battery Configuration Diagram”). This manual does not describe all of the possible configurations.

For optimum operation, the inverter should be placed or mounted on a flat surface; ideally, a normally cool metal surface to help diffuse the heat that is generated. Two cables (see the “Battery Configuration Diagram”) are not supplied, but will be required to allow for full power operation and to provide flexibility in positioning the inverter.

Operating Environment

Do not locate inverters in an area, room or compartment where explosives or flammable fumes might be present, such as engine rooms, engine compartments, or small, unvented battery compartments.

To avoid possible dangerous conditions, the inverters must be located where: 1.The unit is kept dry;

2.Air temperature is between 30°F (–1°C), non-condensing, and 105° F (40°C);

3.At least three inches of clearance from other objects is maintained for cooling airflow; 4.The unit is not exposed to direct heat, sunlight or to explosive or flammable fumes; and 5.The unit is as close to the DC power source as possible.

CAUTION: TO AVOID DAMAGE TO THE INVERTER OR EQUIPMENT USED WITH THE INVERTER:

CAUTION: TO AVOID DAMAGE TO THE INVERTER OR EQUIPMENT USED WITH THE INVERTER:

•Never connect the chassis ground wire from the inverter to the DC negative input.

•CHECK to ensure that the combined loads of the appliances being powered by the inverter DO NOT continuously exceed the inverter’s wattage rating.

•NEVER place items on or over the inverter during operation.

•MAXX SST™ inverters generate heat during operation and must be placed where cool air can circulate to the internal fan, and hot air can be removed.

Installation Procedures

When wiring the inverter to a 12 volt DC power source, ensure that polarity is correct. Reversed polarity will blow a fuse and may cause permanent damage to the inverter. Review “Back View” diagrams on page 4, if necessary, to identify the location of the DC terminals.

Note: The manufacturer’s warranty does NOT cover damage due to reversed polarity.

Temporary Installation

For Temporary Installation, only use the provided 3 feet long cables each using #2AWG wire terminated with a ring terminal attached at the battery (power source) end and a Special Crimp Connector attached at the inverter end. The Special Crimp Connectors are designed for proper connection to the 12 volt input power terminals on the inverter; connection using any other method is not acceptable.

1.Check to be sure the inverter’s ON/OFF Power Switch is in the OFF position and that no flammable fumes are present.

2.Locate the Positive (+, POS) and Negative (-, NEG) terminals on the 12 Volt DC battery (or other 12VDC power source).

3.Locate the Positive (Red, +) and Negative (Black, -) DC input terminal on the inverter.

4.Connect the Special Crimp Connectors of the Positive (Red, +) cable to the Positive (Red, +) terminal on the inverter and tighten the set screws against the flat side of the connectors.

5.Connect the ring terminal of the Positive (Red, +) cable to the Positive (Red, +) terminal on the 12 Volt DC battery (or other 12VDC power source).

6.Connect the Special Crimp Connector of the Negative (Black, -) cable to the Negative (Black, -) terminal on the inverter and tighten the set screws against the flat side of the connector.

7.Connect the ring terminal of the Negative (Black, -) cable to the Negative (-, NEG) terminal on the 12 Volt DC battery (or other 12VDC power source). There may be some minor sparking when the cable is touched to the battery terminal.

WARNING: If persistent, severe arcing occurs between the cable and battery terminals, immediately cease attempting to make the connection and correct the cause of the problem before continuing.

WARNING: If persistent, severe arcing occurs between the cable and battery terminals, immediately cease attempting to make the connection and correct the cause of the problem before continuing.

8.Ensure that all of the electrical connections have been tightened.

9.Set the inverter’s ON/OFF Power Switch to the ON position and verify the Green Power LED Indicator illuminates and the Red Fault LED Indicator does not illuminate.

10.As a test, plug in a lamp with a 60 or 100 Watt light bulb into one of the inverter’s 120 Volt AC Outlets and switch the lamp ON. If the lamp lights normally, the inverter is functioning properly and use of the inverter with other appliances can continue. If the lamp does not light, or does not operate normally:

A.Refer to the “Fault Protection and Troubleshooting Guide” of this Instruction Manual for suggested solutions.

B.If conducting step A does not find and correct the problem, refer to the “Service Information” section of this Instruction Manual for assistance.

Permanent Installation

The permanent installation of the inverter and the required wiring and safety devices to the 12 Volt DC power source must be performed by a professional installer. Further requirements are:

1.The inverter is supplied with 2 Special Crimp Connectors to connect the power source wiring to the inverter DC input terminals. They are designed to be crimped onto #2AWG copper conductor cables (not supplied).

2.The #2AWG power source cables must not exceed 6 feet in length.

3.A 200 Amp ANL Fuse (not supplied) installed in the proper Fuse Holder (not supplied) must be connected in- line as part of the positive power source input cable as close as possible to the power source connections.

4.A #12AWG insulated wire should be connected between the Grounding Terminal on the inverter (see “Controls and Functions”, “Back View Diagram” on page 4 ) and the ground terminal on the appliance (such as a TV or Radio) to minimize electrical noise and reception interference.

CAUTION: Do not connect this wire to the inverter’s Negative (Black, -) DC input terminals.

CAUTION: Do not connect this wire to the inverter’s Negative (Black, -) DC input terminals.