1415 specifications

The Blodgett 1415 is a highly efficient commercial convection oven designed to meet the demands of busy kitchens. Known for its durability and performance, the Blodgett 1415 is a popular choice among chefs and restaurateurs who seek reliable cooking equipment that can deliver consistent results.One of the main features of the Blodgett 1415 is its spacious cooking capacity. With multiple racks, this oven allows for cooking several dishes simultaneously, maximizing kitchen efficiency. Its size is perfect for bakeries, restaurants, and catering services, where large batches of food need to be prepared at once.

The oven's advanced heating technology ensures even heat distribution throughout the cooking chamber. This results in perfectly cooked meals, whether baking, roasting, or reheating. The Blodgett 1415 features a powerful fan that circulates hot air, promoting an even cooking environment. This convection technology allows for reduced cooking times and energy savings, making it an excellent choice for high-volume cooking operations.

Another significant characteristic of the Blodgett 1415 is its user-friendly digital controls. The intuitive interface allows chefs to easily set temperatures, timers, and cooking modes with precision. The oven also has several programmable settings, enabling operators to save time and streamline food preparation.

Safety is a key consideration in the design of the Blodgett 1415. The oven is built with a double-layered door that minimizes exterior heat, reducing the risk of burns. The door is also equipped with tempered glass, allowing staff to monitor cooking progress without opening the oven, further promoting energy efficiency.

The Blodgett 1415 is constructed from high-quality stainless steel, ensuring durability and ease of cleaning. Its robust design is built to withstand the rigorous demands of a busy kitchen, resisting scratches and corrosion over time. The oven's smooth surfaces allow for quick wipe-downs, promoting hygiene in food preparation areas.

In conclusion, the Blodgett 1415 convection oven combines functionality, efficiency, and safety, making it a vital piece of equipment for any professional kitchen. With its advanced technologies, spacious capacity, and user-friendly design, the Blodgett 1415 stands out as a top choice for culinary professionals committed to quality cooking.

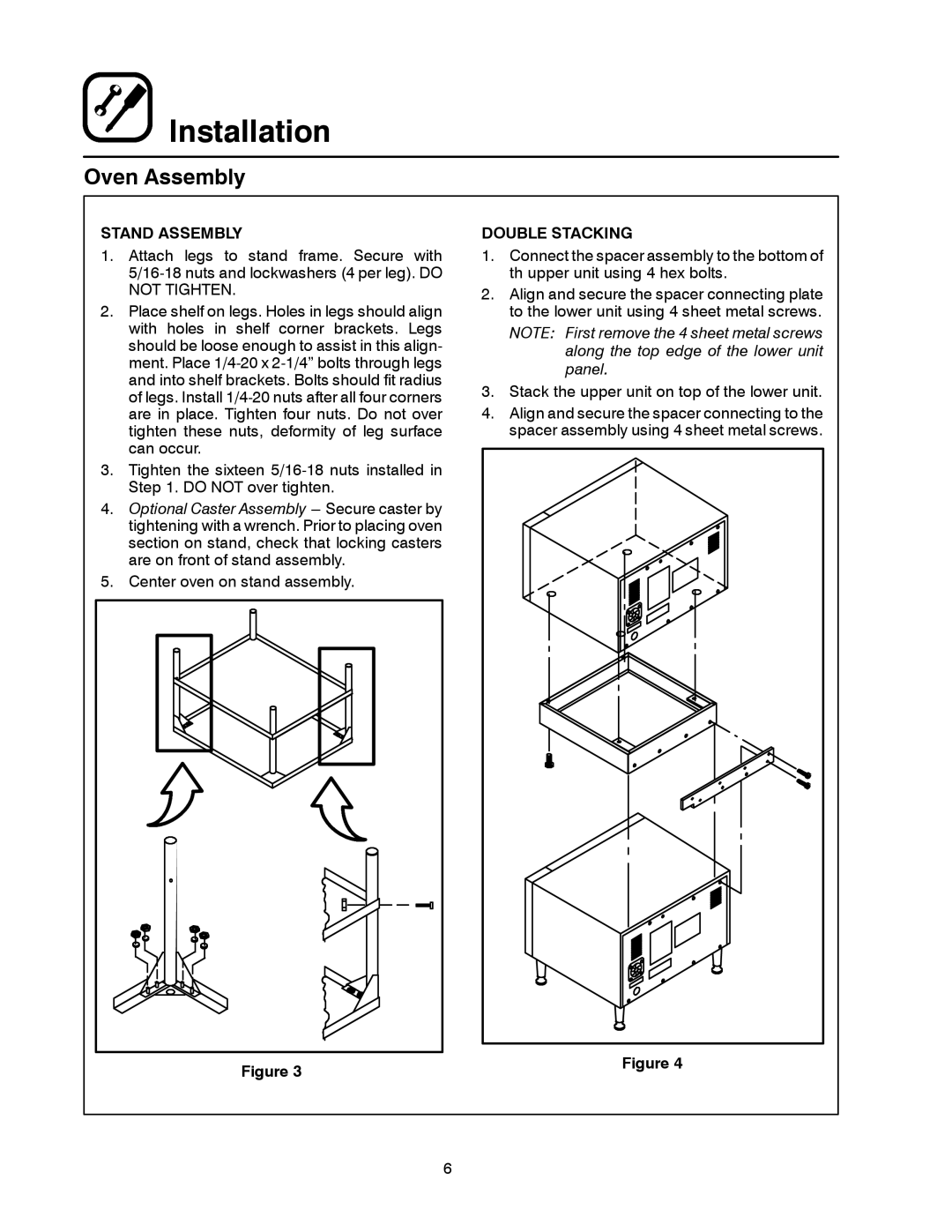

Installation

Installation